Mouth-protecting pipe piece, its making method and using method

A flaring pipe and integrated technology, applied in the field of flaring pipe fittings, can solve the problems of troublesome and time-consuming connection between pipes, complicated installation and connection procedures, cumbersome preparation work, etc., to reduce the risk of leakage, convenient installation of pipe connections, and easy installation The effect of reduced prep work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

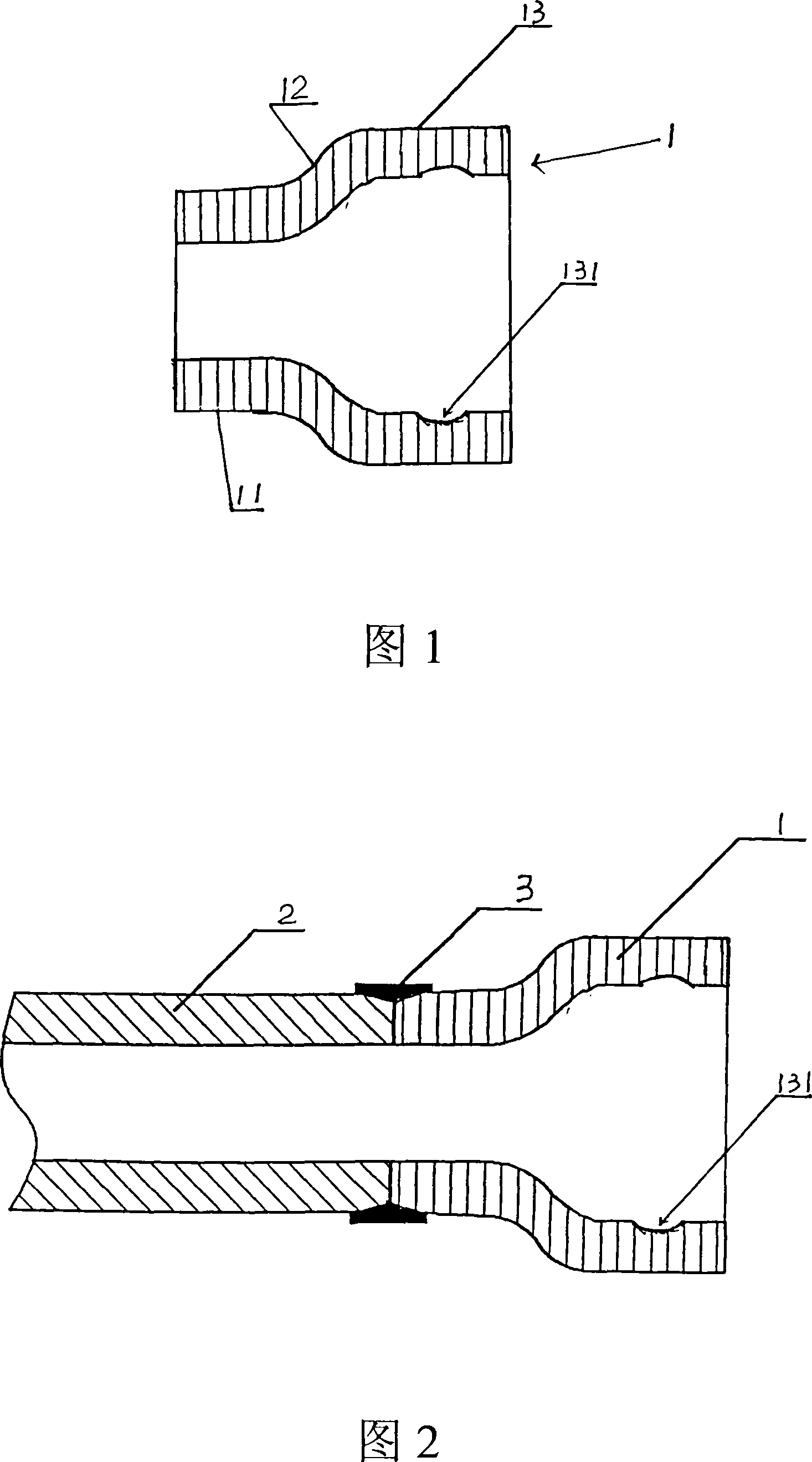

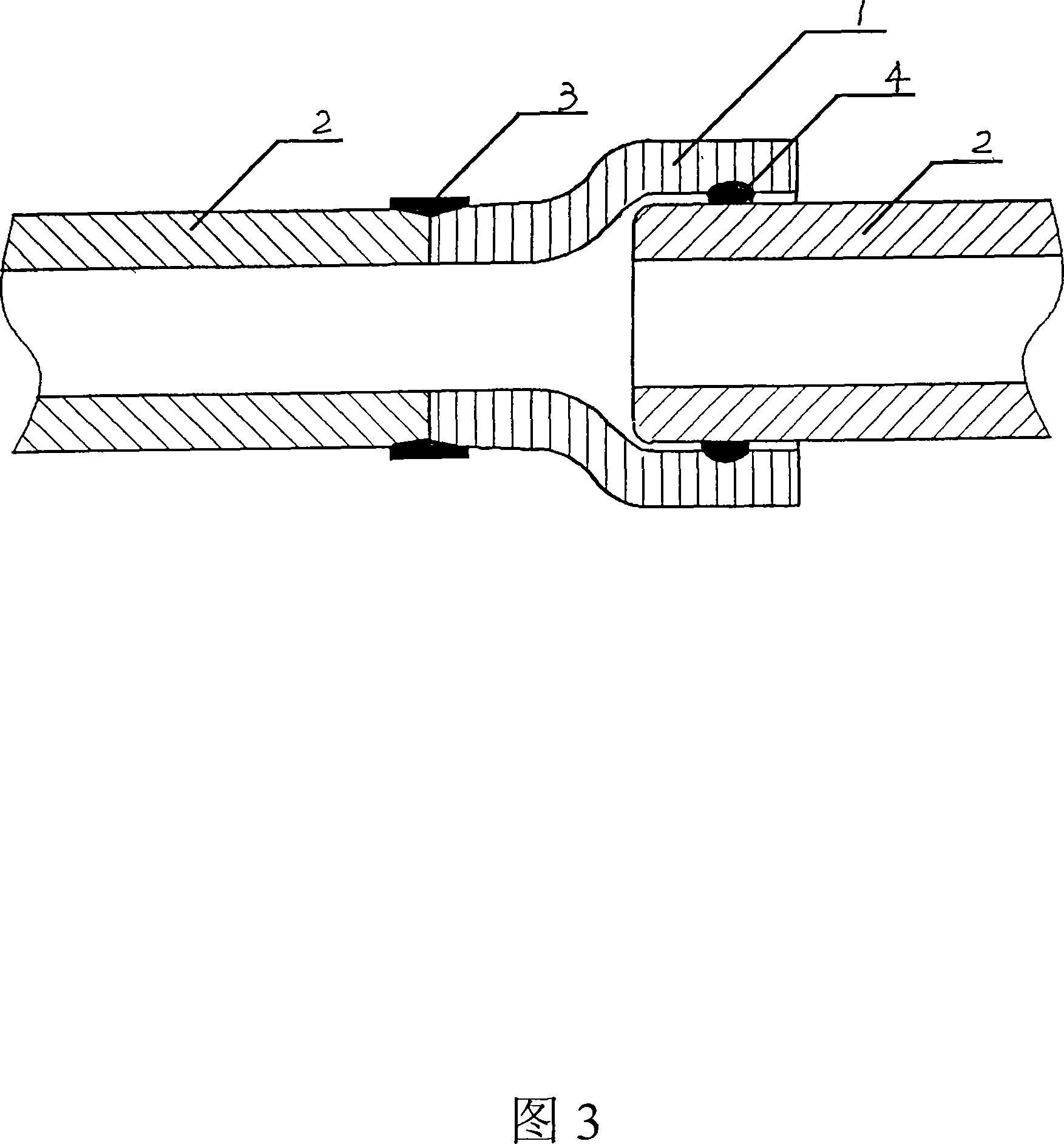

[0023] Referring to Fig. 1, referring to Fig. 2 and Fig. 3, the flared pipe fitting 1 of the present invention is used to connect the plastic winding structure wall pipe material 2, and it includes a straight pipe section 11, a flared section 12 and a socket section 13 which are sequentially integrated into one , the diameter of the straight pipe section 11 is adapted to the diameter of the connected pipe material 2 , and the inner diameter of the socket section 13 is larger than the outer diameter of the connected pipe material 2 . The inner wall of the socket section 13 is provided with a sealing groove 131 for embedding the expansion rubber ring.

[0024] The manufacturing method of the flaring pipe fitting 1 of the present invention is to use the same plastic as the plastic used to manufacture the plastic winding structure wall pipe 2 as a raw material, and adopt the method of pouring molding to make it.

[0025] The usage method of flared pipe fitting 1 of the present inv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com