Stage device

A technology of loading stage and bench, which is applied in the direction of feeding device, large fixed member, instrument, etc., can solve the problems of difficult transportation, stone and stone processing, etc., and achieve the effect of reducing the moving range, saving space and compact structure of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

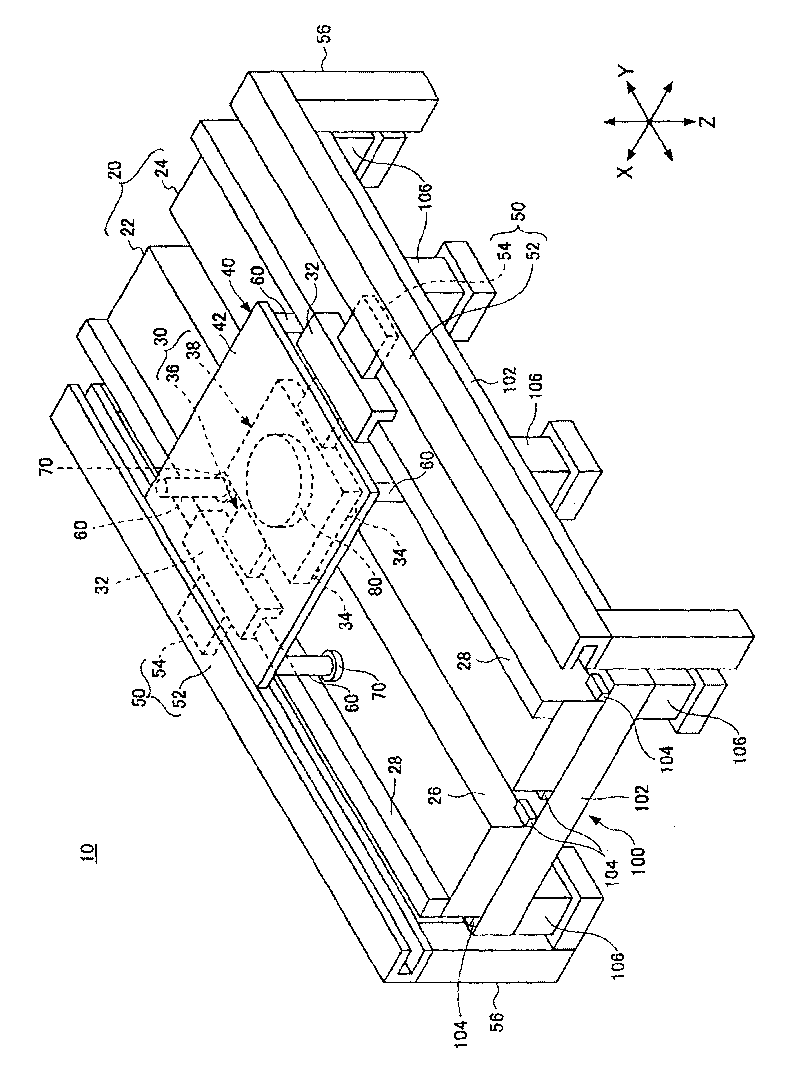

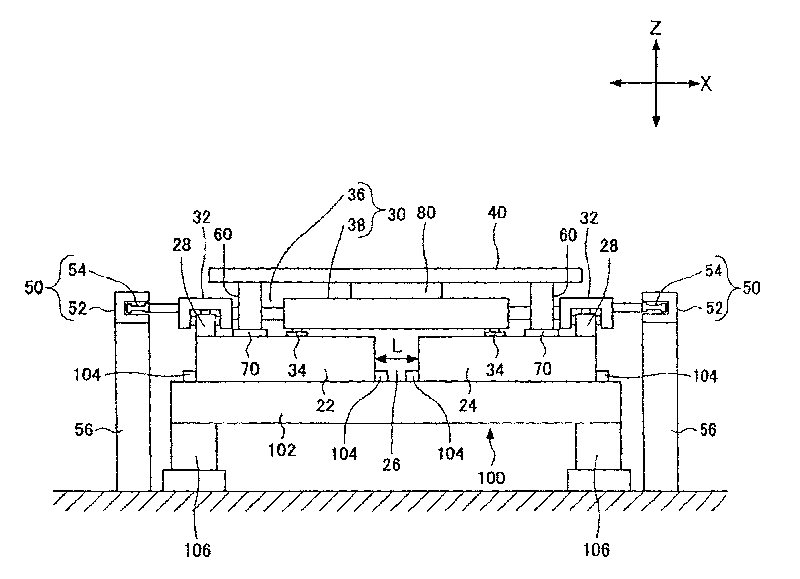

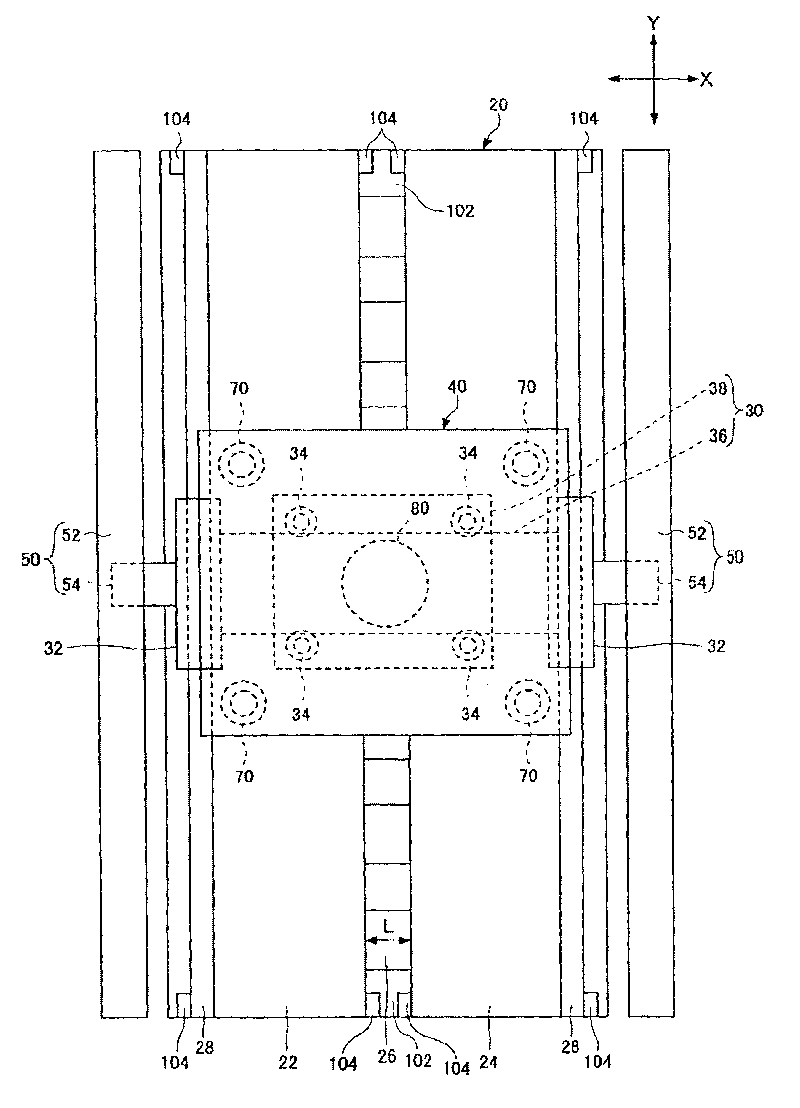

[0025] figure 1 It is a perspective view showing an embodiment of the stage device of the present invention. figure 2 for figure 1 Front view of the stage assembly shown. image 3 for figure 1 Top view of the stage assembly shown.

[0026] Such as Figure 1 ~ Figure 3 As shown, the stage device 10 has: a stone platform 20, a stage 30 that moves on the plane of the stone platform 20, and a suction disc that is placed on the stage 30 and sucks a flat workpiece (not shown in the figure) 40. A pair of Y linear motors 50 for moving the stage 30 in the Y direction.

[0027] The stone platform 20 is composed of stone platform halves 22 , 24 divided into two parallel parts along the moving direction (Y direction) of the stage 30 , and the pair of stone platform halves 22 , 24 are supported by the same stand 100 . A gap 26 extending in the Y direction is formed between the pair of stone platform half bodies 22 and 24 . The gap 26 is formed in an unused area through which an air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com