Flexible filler embedder and concrete panel seaming method

A technology of concrete panels and flexible fillers, which is applied in water conservancy projects, sea area projects, dams, etc., can solve the problems of low artificial embedding efficiency, difficult operation, and poor quality, and achieve easy equipment maintenance, simple procedures, and simple equipment. Effect

Inactive Publication Date: 2007-09-05

张明军

View PDF1 Cites 6 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

2. The operation is difficult

3. Low efficiency

In summary, in order to solve the problems of low efficiency and poor quality of manual filling, and eliminate the shortcomings of the prior art, the present invention proposes a flexible filling machine for face rockfill dams

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

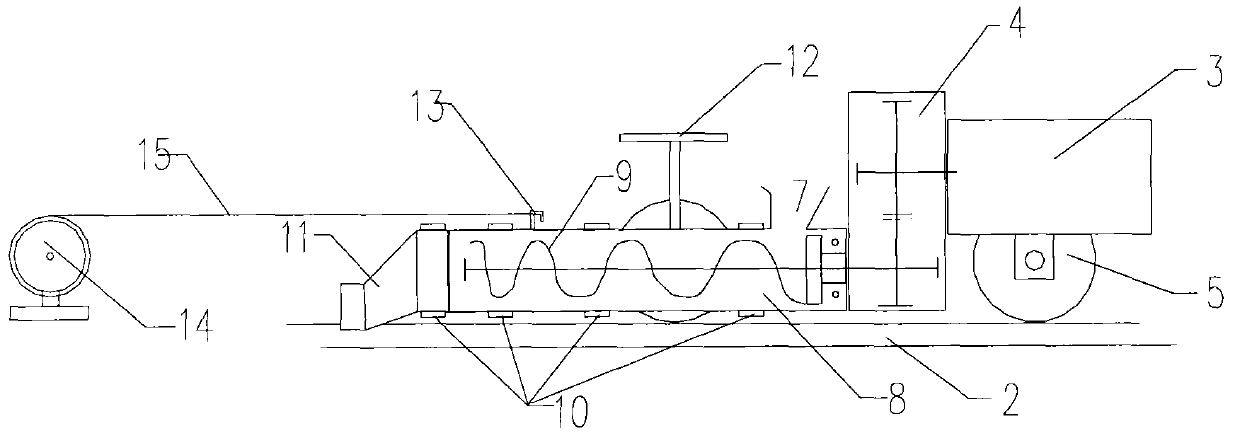

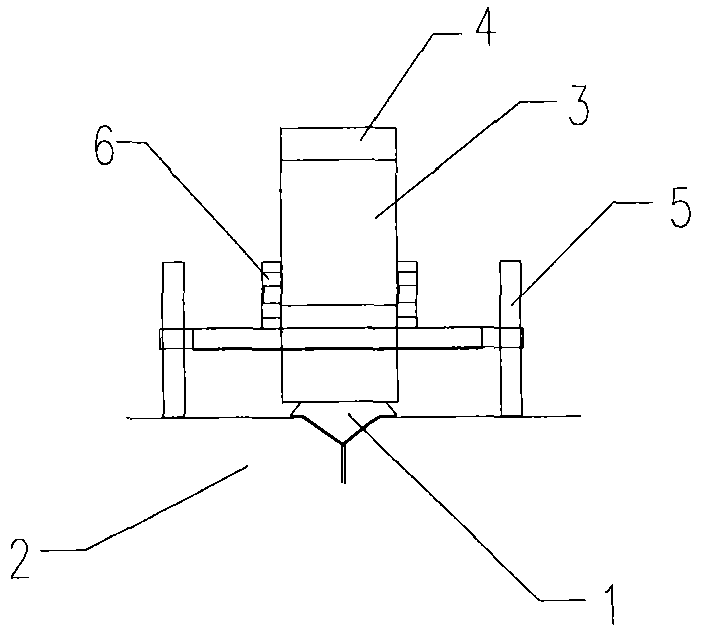

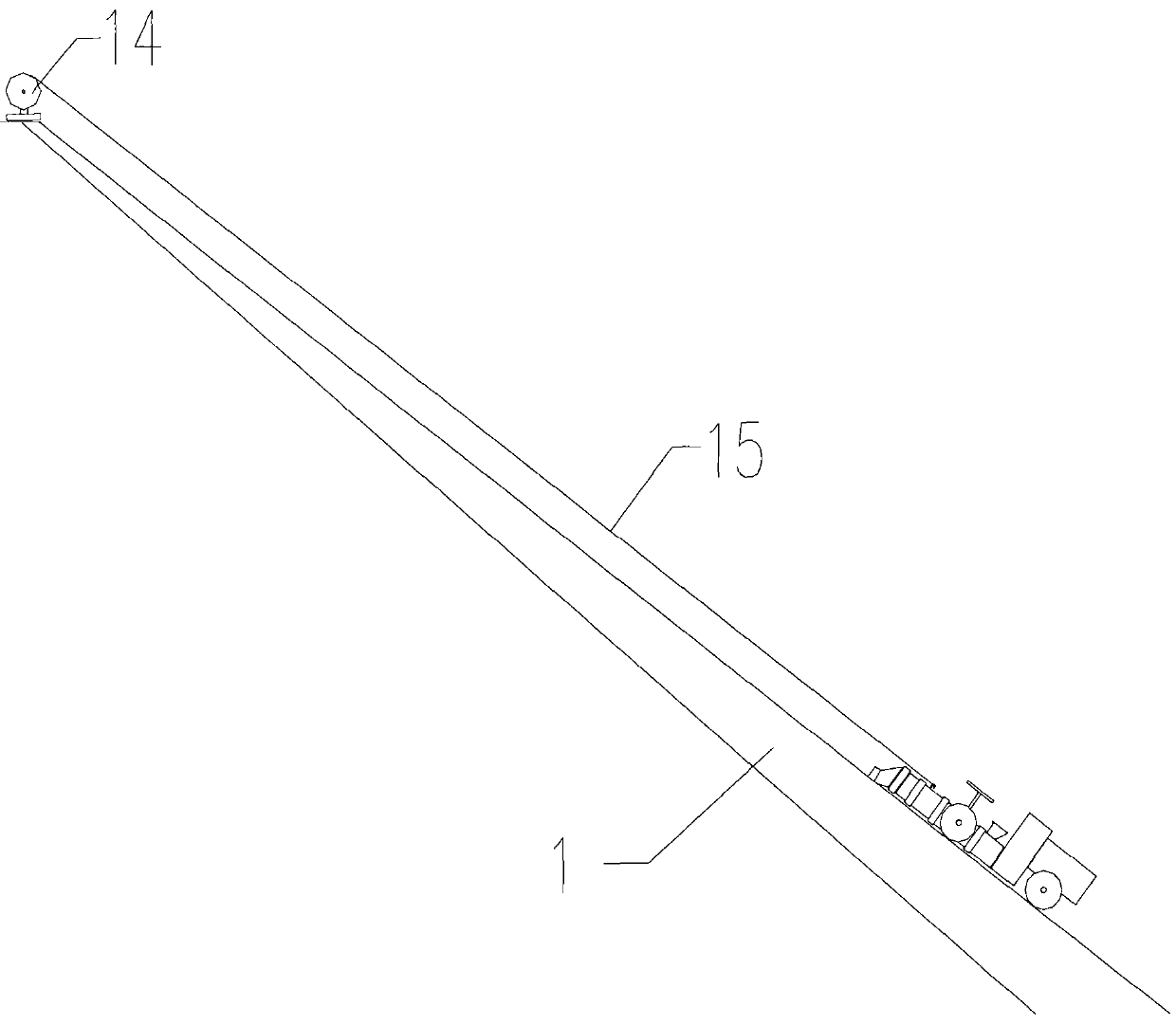

A stuffing machine for filling concrete plate along stone dyke is composed by machine body and two wheels on body's two sides. The body includes a motor, which is connected through a speed regulator to screw extruder in a hopper, at least one heater along the material moving line, a mode head at the hopper outlet for shape control of extruded material.

Description

technical field The invention relates to engineering machinery and engineering methods, in particular to a flexible filler embedding machine for embedding flexible fillers in concrete face joints of face rockfill dams and a concrete face joint method. Background technique The concrete face rockfill dam is a dam form widely used in the construction of hydropower stations at home and abroad. It uses the rockfill body as the main force-bearing structure to bear the reservoir water pressure, and the reinforcement poured from bottom to top on the facing surface of the rockfill body Concrete panels are anti-seepage structures. Due to factors such as the settlement and deformation of the dam body, the concrete panels need to be poured in blocks, so that dozens of joints are formed between the panel blocks, the plinth and the panel blocks that are integrated with the surrounding mountains. Seepage, the seepage will take away the small particles in the rockfill body, forming a grad...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): E02B3/16E02B7/06

Inventor 张明军

Owner 张明军

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com