Driving circuit and reset circuit for plasma display panel

A display panel and reset circuit technology, which is applied in the direction of identification devices, static indicators, instruments, etc., can solve the problem that the resonance of the maintenance circuit 101 is different from the resonance of the reset waveform, the maintenance period of the display unit is shortened, and the capacitor Cp is overvoltage Slow down and other issues to achieve the effect of shortening the reset period, improving display quality, and shortening the reset period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

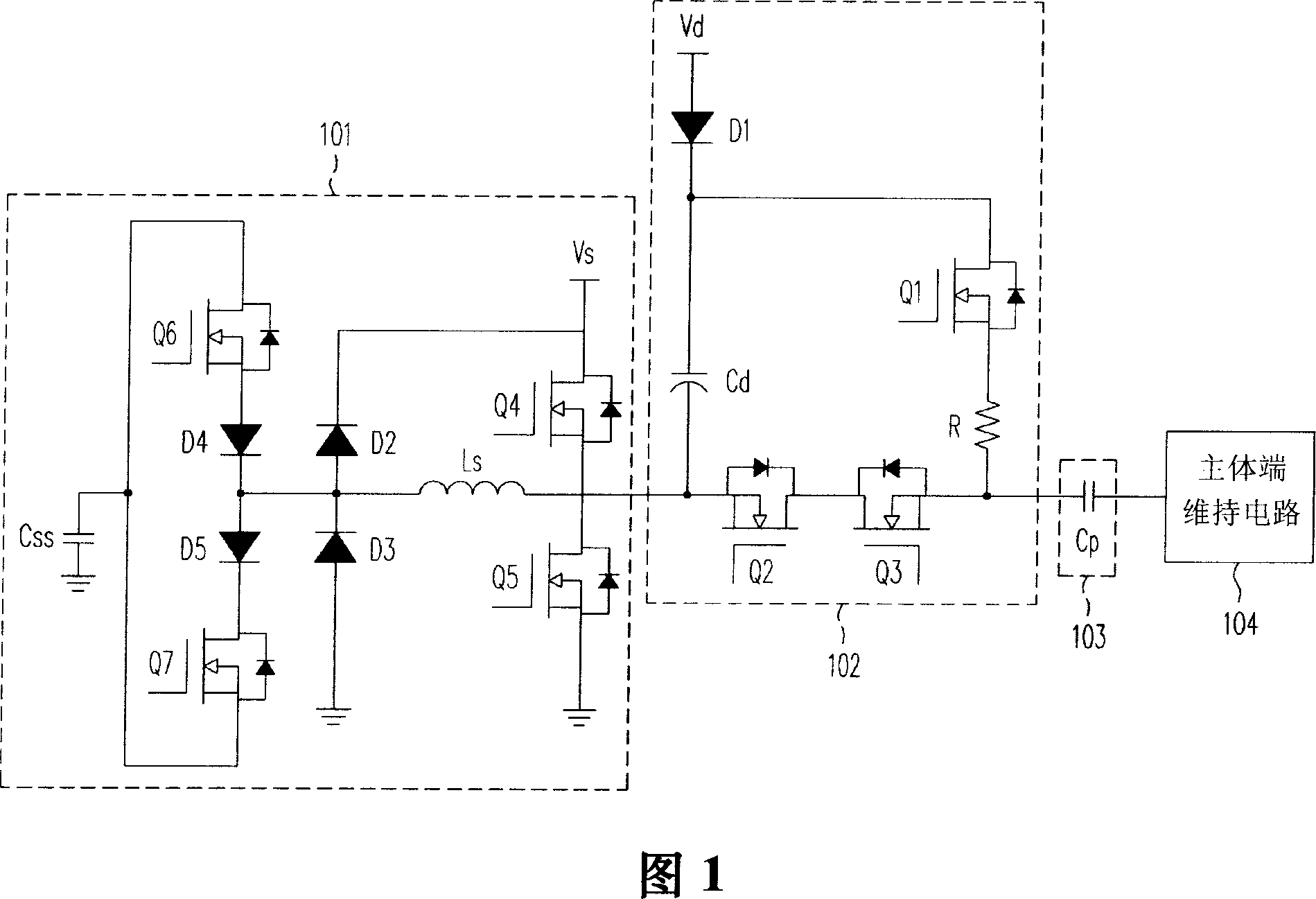

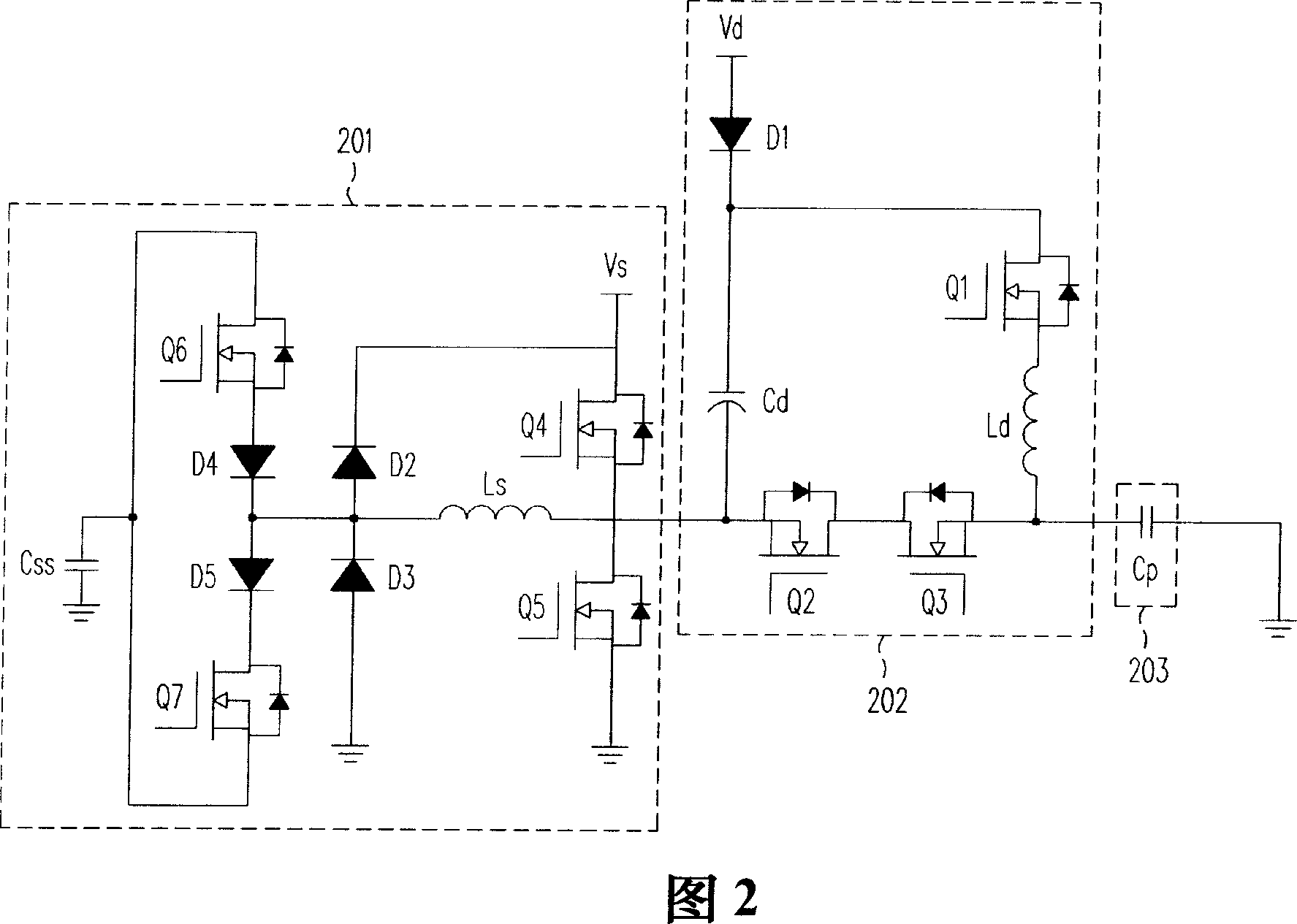

[0031] FIG. 2 is a schematic diagram of a PDP driving circuit according to an embodiment of the invention. The driving circuit in FIG. 2 includes a reset circuit 202 and a sustain circuit 201 . The reset circuit 202 is electrically connected to one of the display units 203 of the PDP, and generates a reset waveform of the display unit 203 by LC resonance. The sustain circuit 201 provides a sustain voltage to the display unit 203 during the sustain period.

[0032] The main difference between the reset circuit 202 of Fig. 2 and the reset circuit 102 of Fig. 1 is that the resistor R of Fig. 1 is changed into the inductor Ld of Fig. 2, and its purpose is to change the traditional resistance-capacitor resonance into the inductance of the present invention Capacitive resonance. On the other hand, the architecture of the sustain circuit 201 in FIG. 2 is the same as that of the sustain circuit 101 in FIG. 1 . The reset circuit 202 of this embodiment is electrically connected to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com