Mechanical rope tightening device

A rope tensioner and mechanical technology, applied to wire tensioning appliances, motor vehicles, vehicles used for freight, etc., can solve the problems of affecting transportation safety, poor reinforcement effect, and cargo displacement, etc., to achieve convenient use and structural Simple, low-cost-to-manufacture effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

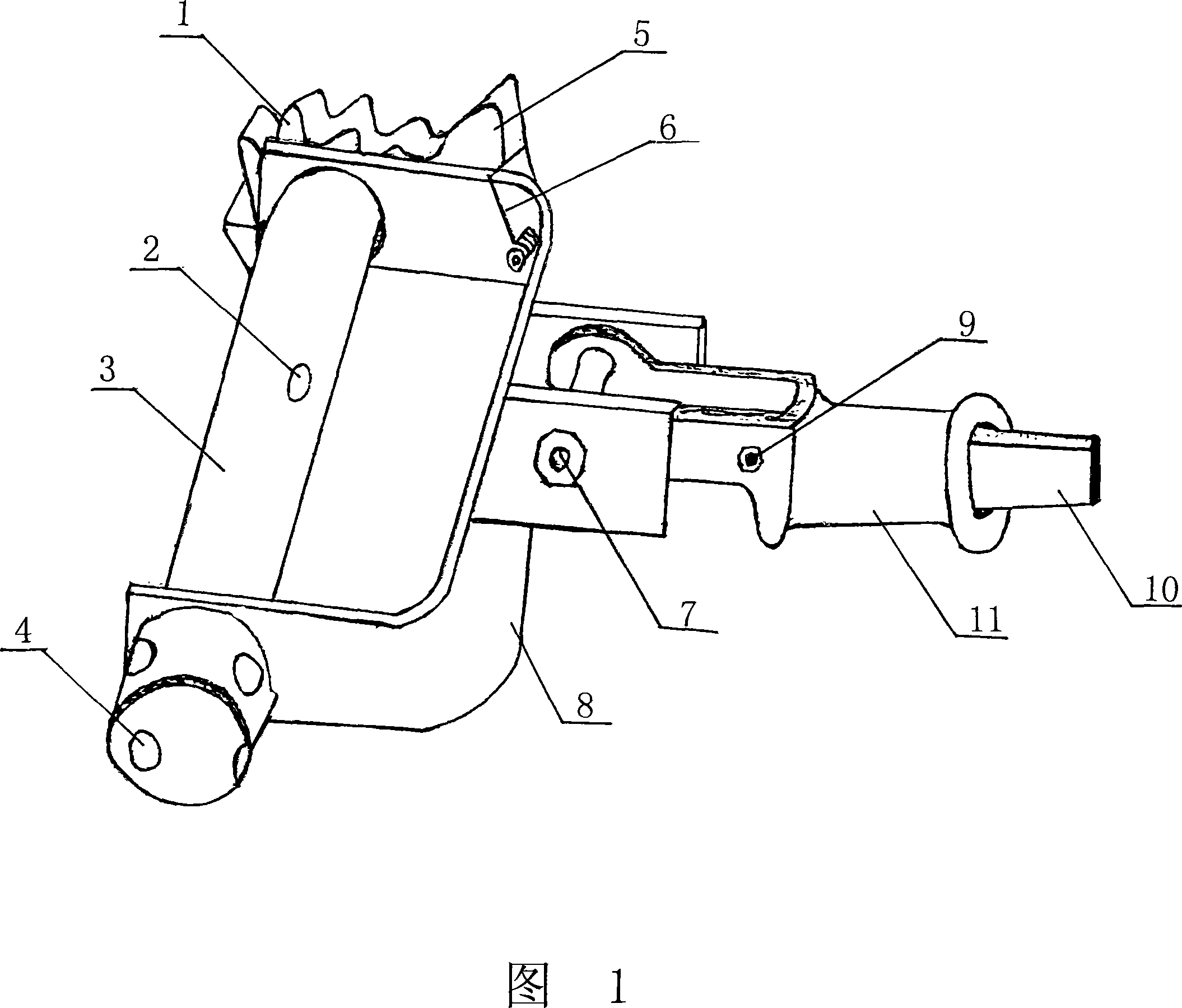

[0012] The invention consists of steel processing, steel castings and bolt components. The U-shaped seat 8 is provided with a rope reel 3, and at least one rope hole 2 is provided on the rope reel 3. The hole is used to pass a steel wire rope for fastening. One end of the rope reel 3 is provided There is a non-return ratchet wheel 1, and the other end is provided with a handle hole 4, the said non-return ratchet wheel 1 is provided with a tongue 5 in the wheel groove, the tongue 5 is equipped with a return spring 6, and the tongue 5 has a return spring 6 Under the action, it is stuck in the wheel groove of the anti-retraction ratchet 1 so that it cannot be reversed. Only the anti-retraction ratchet 1 can reverse when the tongue 5 is removed. An automatic locking assembly is provided on the top of the U-shaped seat 8. The automatic locking assembly includes a fixed seat 7, a locking sleeve 11 is provided on the fixed seat 7, and a stop bolt 9 is provided on the locking sleeve 11 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com