Disk brake

A disc brake and brake caliper technology, applied in the direction of brake type, brake components, axial brake, etc., can solve the problem of high production cost, and achieve the effects of weight reduction, simple installation, and reduction of external dimensions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

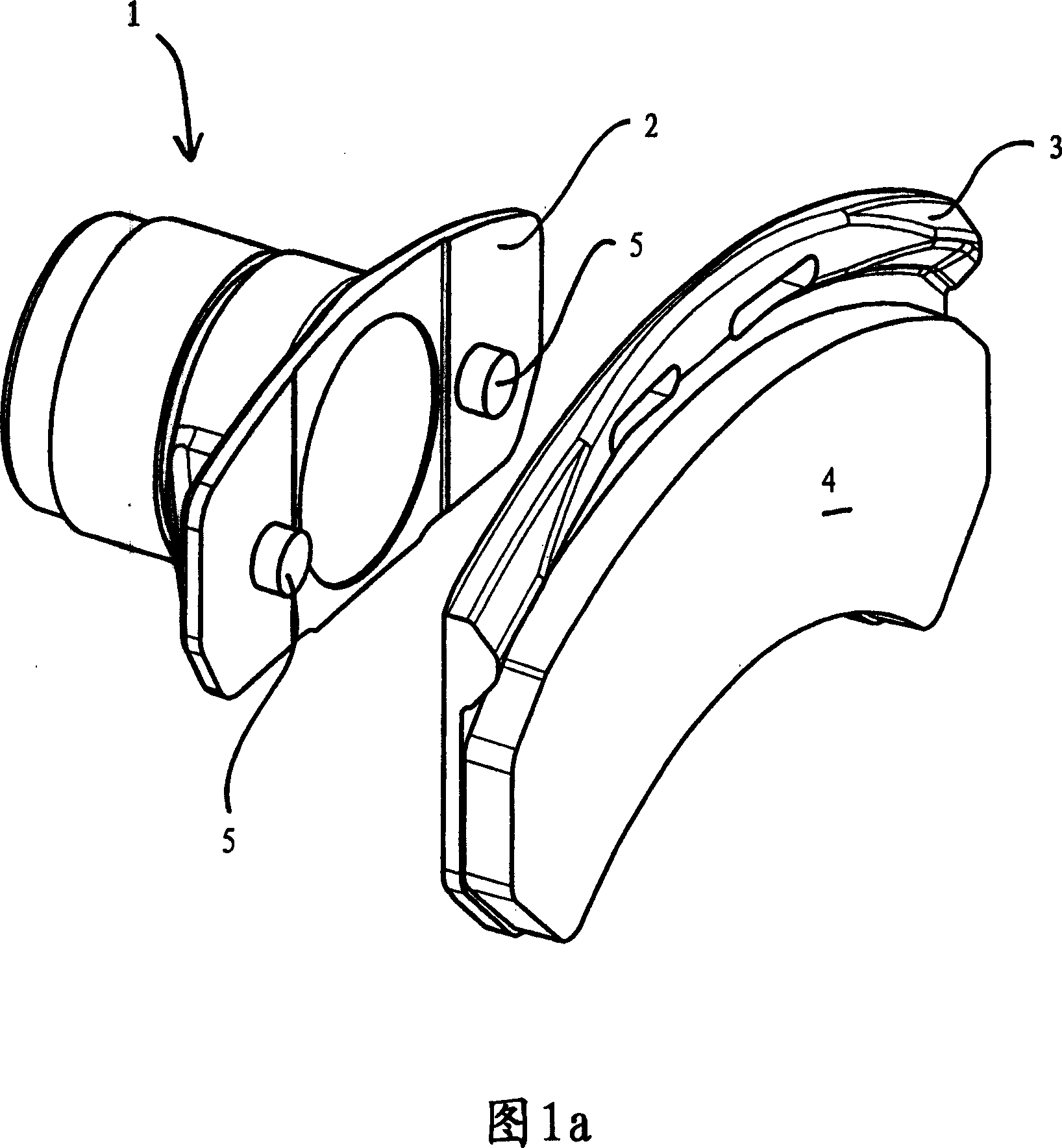

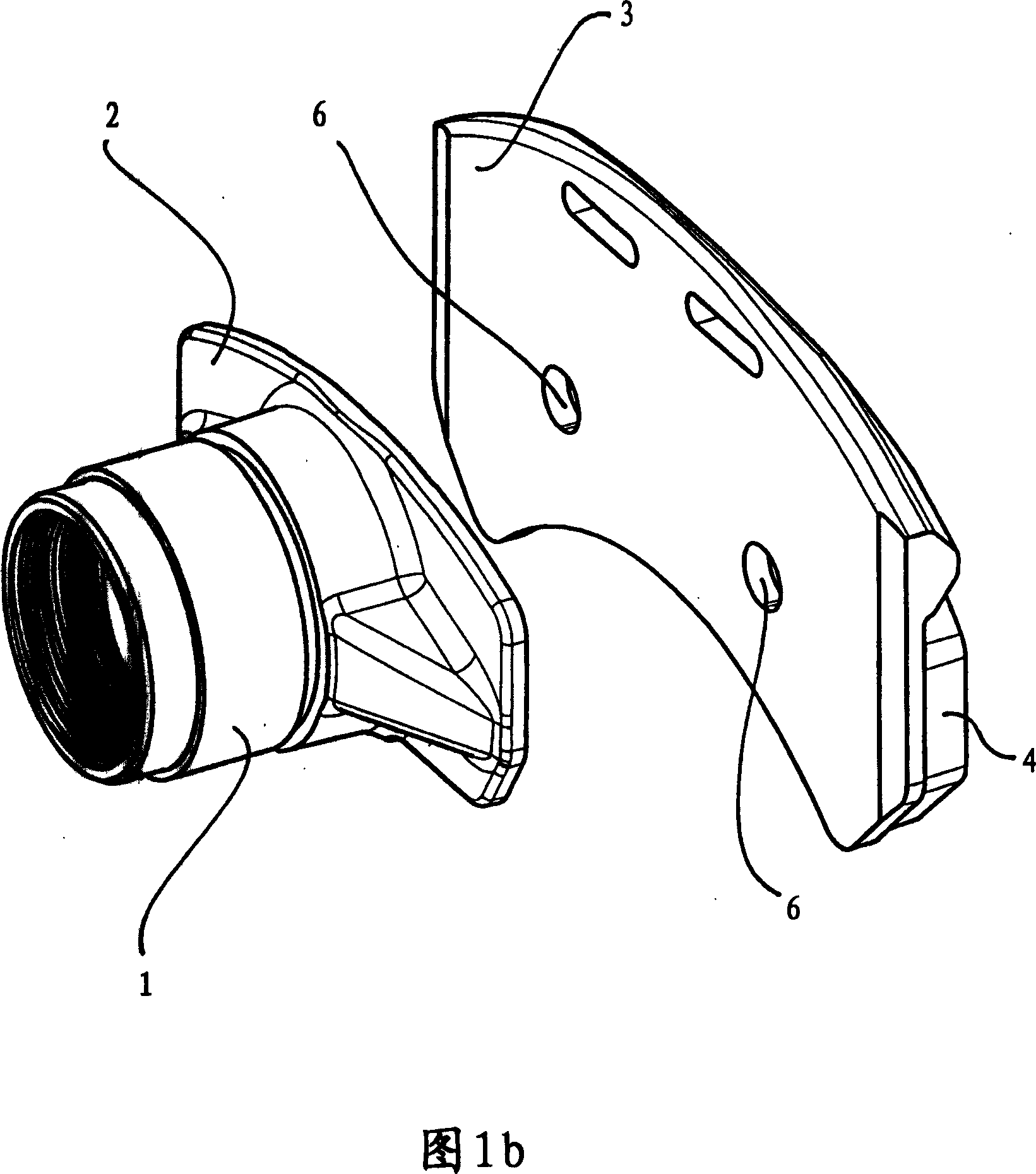

[0044] Figures 1a and 1b are examples of parts of a disc brake according to the first embodiment, including a cylindrical push rod 1 on which the pressure plate is positioned, and a brake pad on which the brake pad 4 is positioned. Holder 3. This push rod 1 is driven by a reinforcing mechanism not shown in detail here and is positioned in the brake caliper housing.

[0045] The pressure plate 2 facing the brake lining holder 3 on its surface has two pin-shaped protrusions 5 which are aligned at a distance from each other.

[0046] As can be seen in FIG. 1b, the brake lining holder 3 has a corresponding recess 6 of complementary form into which the protrusion 5 engages when assembled, preferably allowing some play.

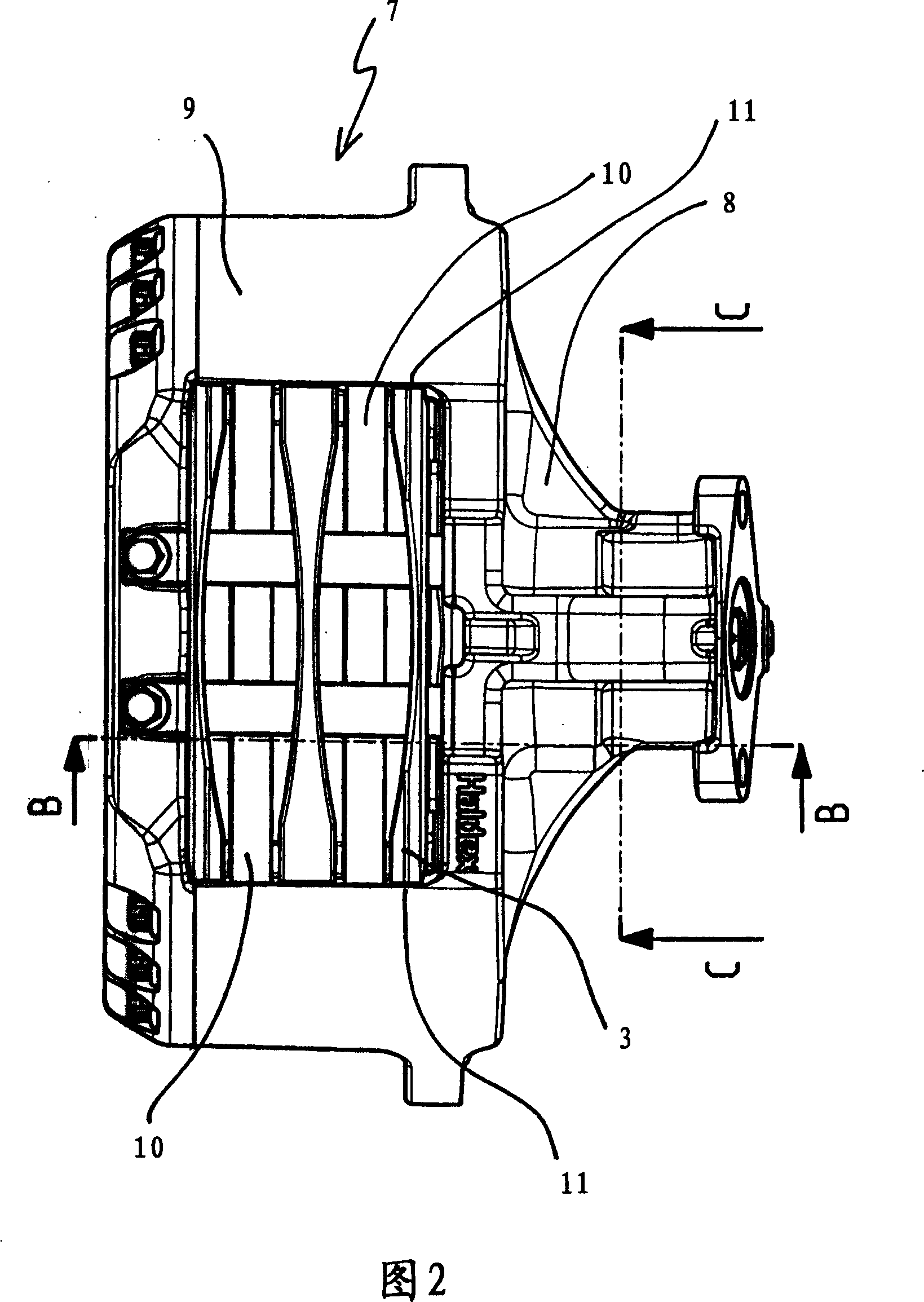

[0047] FIG. 2 shows a disc brake in top view in which the aforementioned elements are integrated.

[0048] The disc brake has a brake caliper 7 and two blades or arms 9 extending over two brake discs 10 , the brake caliper having a caliper housing 8 for accommoda...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com