One-way belt sheave

A pulley, one-way technology, applied in belts/chains/gears, components with teeth, portable lifting devices, etc., can solve the problems of loss of function of one-way pulleys, stuck bearings, affecting the life of generators, etc. Wear, large radial bearing capacity, and the effect of improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

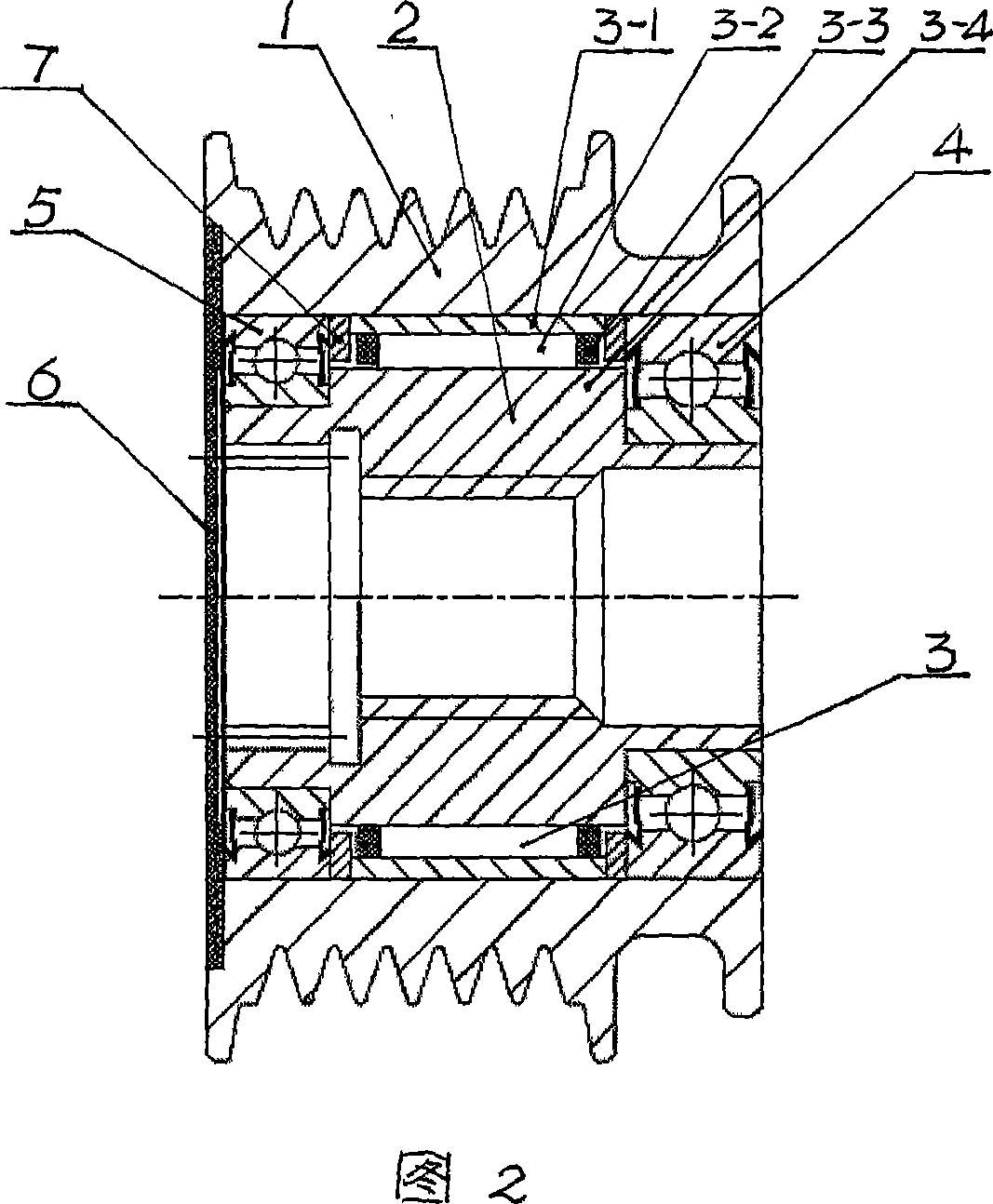

[0024] The one-way pulley shown in Figure 2 has a housing 1 and a mandrel 2, a one-way bearing 3 is installed between the housing 1 and the mandrel 2, and a dust cover 6 is fixedly arranged on one side of the housing 1 . The inner sleeve 3-4 of the one-way bearing 3 is integrated with the mandrel (2), and the material is low-alloy steel or medium carbon steel; the outer sleeve 3-1 of the one-way bearing 3 has no hem, and the material is bearing The two sides of the jacket 3-1 are fitted with retaining rings 7; the two ends of the one-way bearing 3 are respectively provided with main bearings 4 and auxiliary bearings 5, and the main bearings and auxiliary bearings are deep groove ball bearings. , Standard parts, made of bearing steel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com