Method capable of adjusting sensing part lens deviation and its encapsulation structure

A sensing element and packaging structure technology, which is applied in the field of adjustable sensing element lens deviation and its packaging structure, can solve the problems of complicated formation process of controlling the height of the side wall, etc., and achieve the effect of precise lens deviation and precise adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

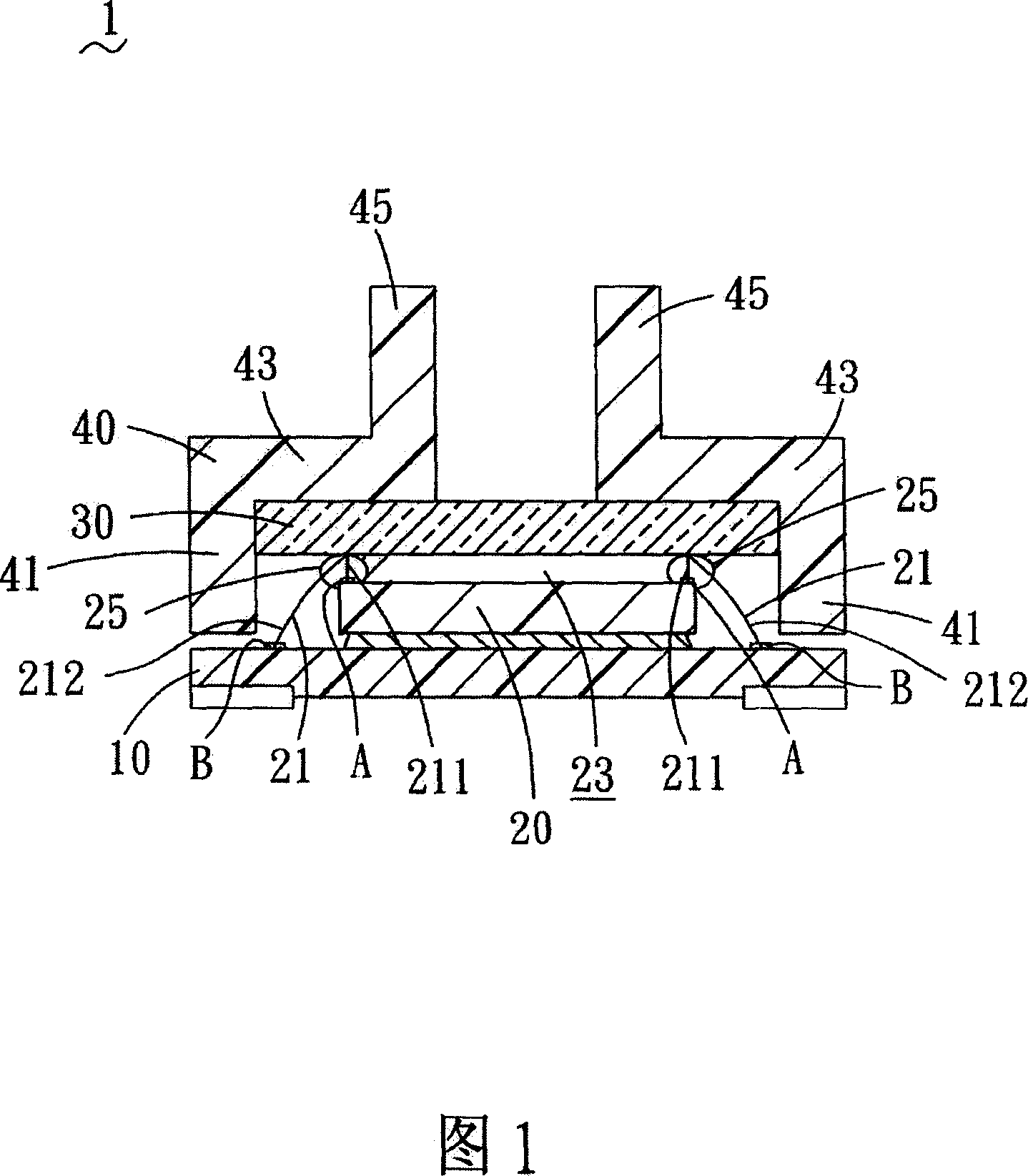

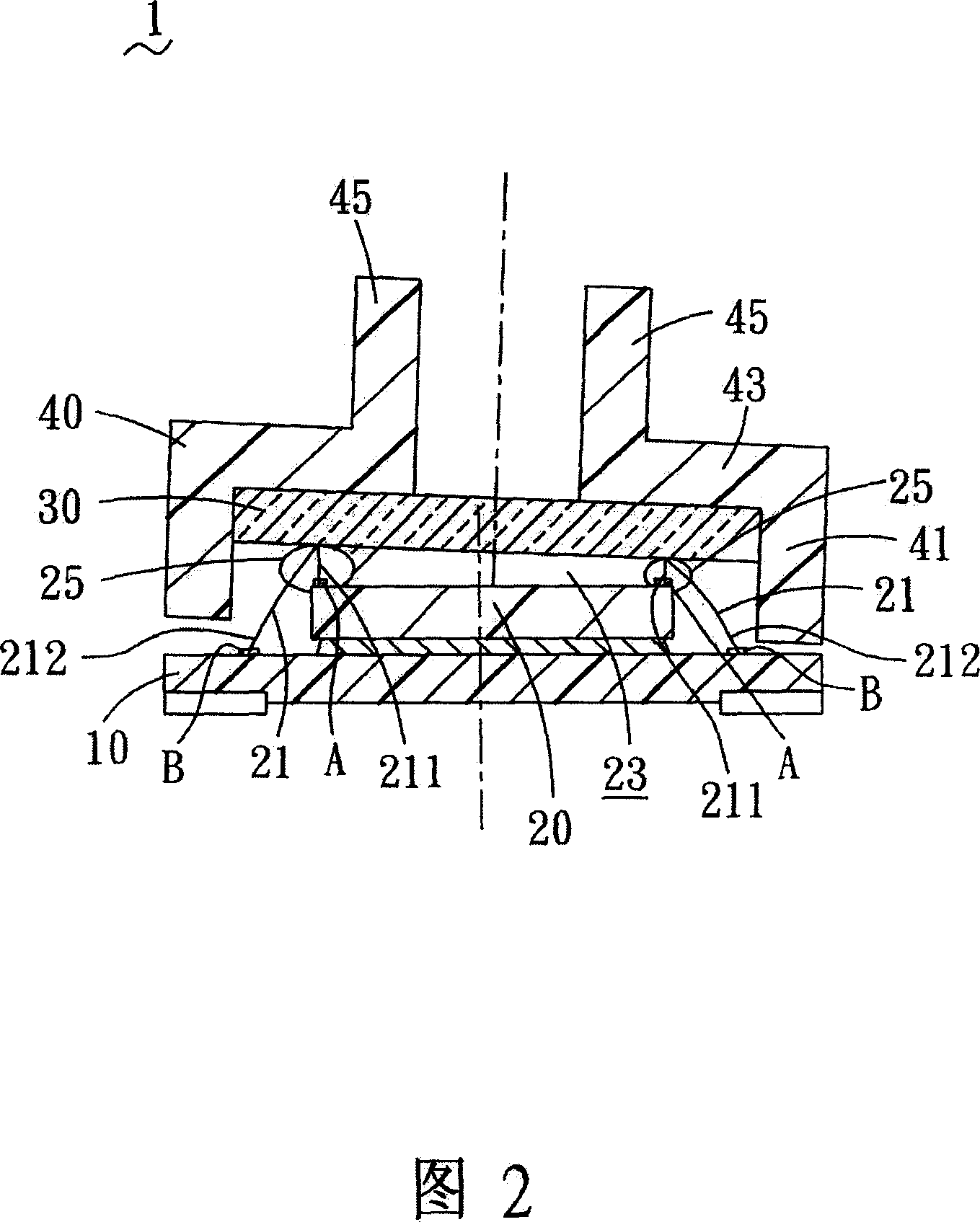

[0030] Please refer to FIG. 1 , the package structure 1 of the present invention which can adjust the lens deviation of the sensing element includes a carrier substrate 10 , a photosensitive chip 20 , a light-transmitting element 30 and a frame 40 covering the elements arranged from bottom to top.

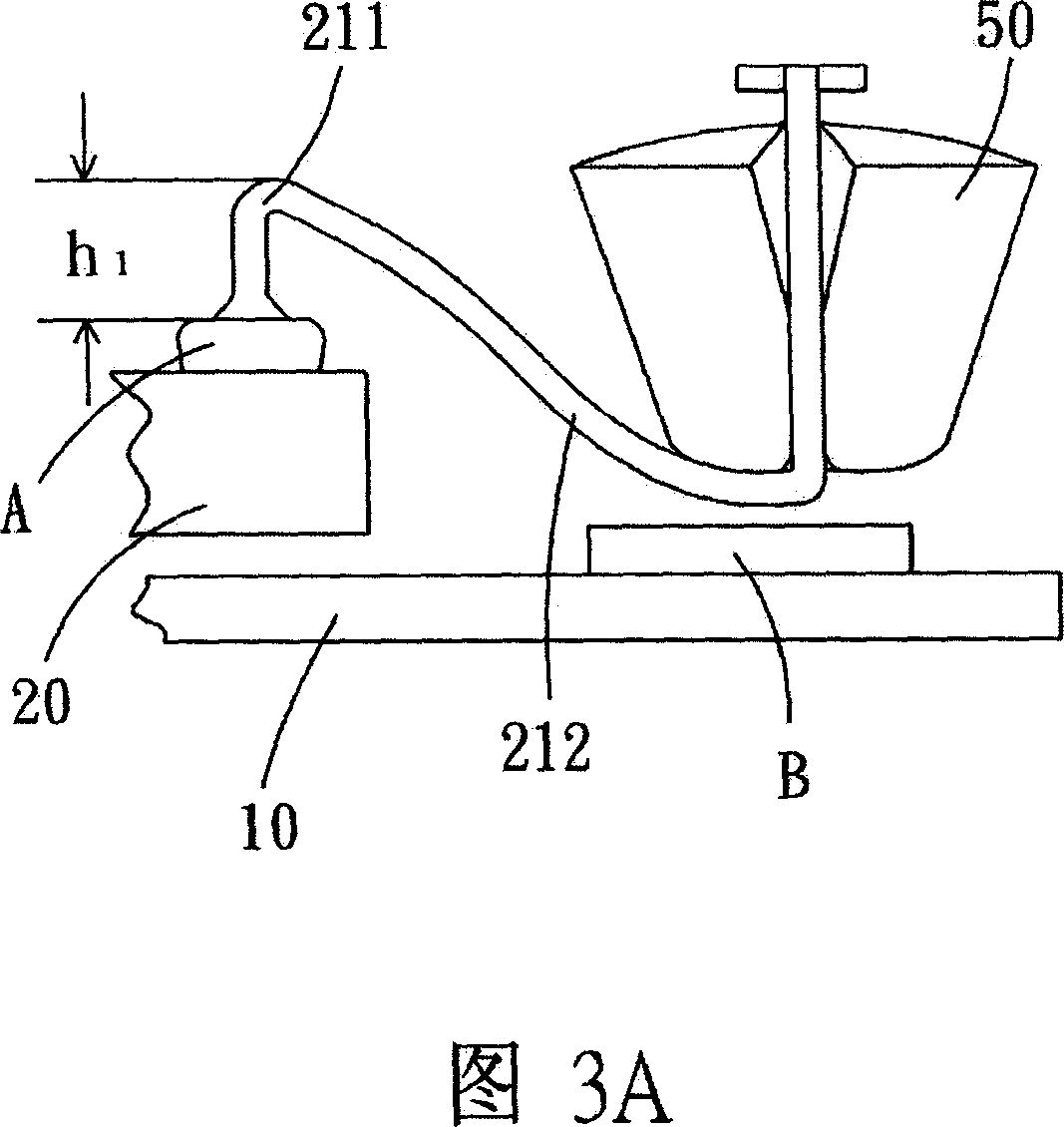

[0031] The photosensitive chip 20 is affixed to approximately the middle of the upper surface of the carrier substrate 10 . The photosensitive chip 20 is provided with a first bonding area A around the upper surface of the photosensitive chip 20 , and the carrier substrate 10 is provided with a second bonding area B around the upper surface. A plurality of metal connecting wires 21 are electrically bonded between the first bonding area A and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com