Underground continuous wall milling joint and construction technique thereof

An underground diaphragm wall and milling technology, applied in sheet pile wall, infrastructure engineering, construction, etc., can solve the problems of joint waterproof effect, difficult mud cleaning, high engineering cost, and meet the requirements of node construction period and good social benefits. , the effect of low engineering cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

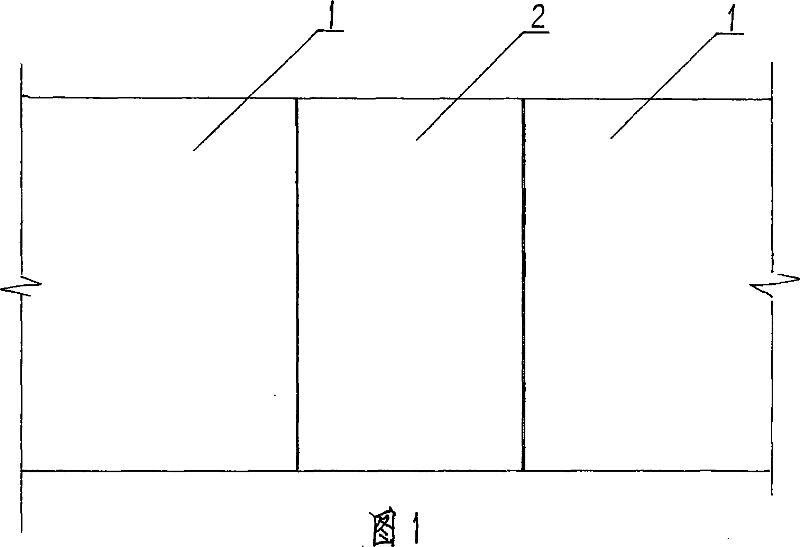

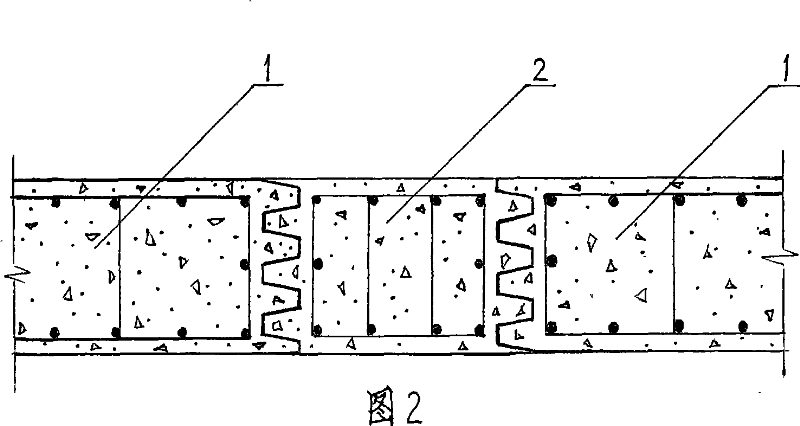

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

[0025] As shown in Figure 1, the underground diaphragm wall milling method joint of the present invention includes two wall end faces opposite to the first-stage groove section of two adjacent underground diaphragm wall 1 sections, and a joint main body 2 is arranged between the two wall end faces The end surface of the wall and the end surface opposite to the joint main body 2 are provided with interengaging corrugated concave-convex bodies, and the joint main body 2 is fixedly connected to the underground continuous wall 1 at both ends through the intermeshing corrugated concave-convex bodies.

[0026] The construction technology of underground diaphragm wall milling method joint of the present invention comprises the following steps:

[0027] (a) Excavate the first-stage slots for pouring two adjacent walls, and the second-stage slots are between the two slots;

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com