Arrangement method for initial mining sublevel stoping drift with sublevel caving method

A technology of subsection caving method and layout method, which is applied to the layout field of the first mining subsection mining approach of the subsection caving method without bottom pillars, can solve the problems of large construction volume, low mining recovery rate and high construction cost, and achieves The effect of saving engineering volume and engineering costs, increasing the amount of ore collapsed, and reducing mining costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

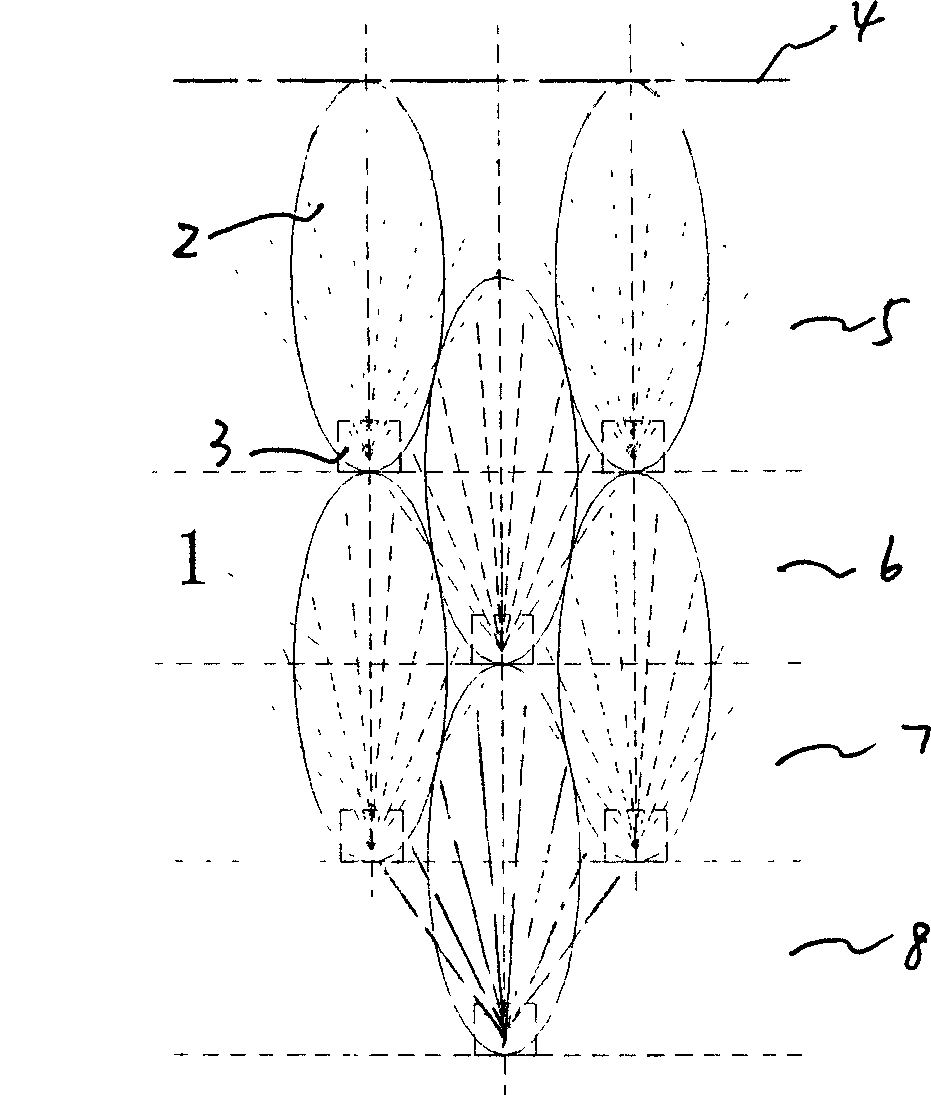

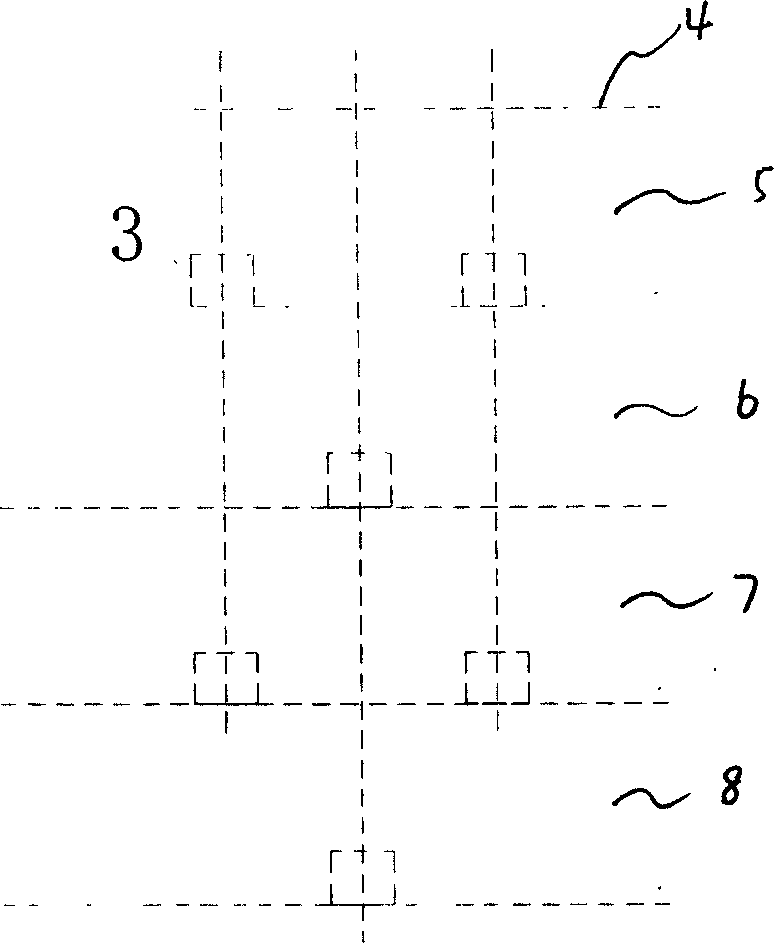

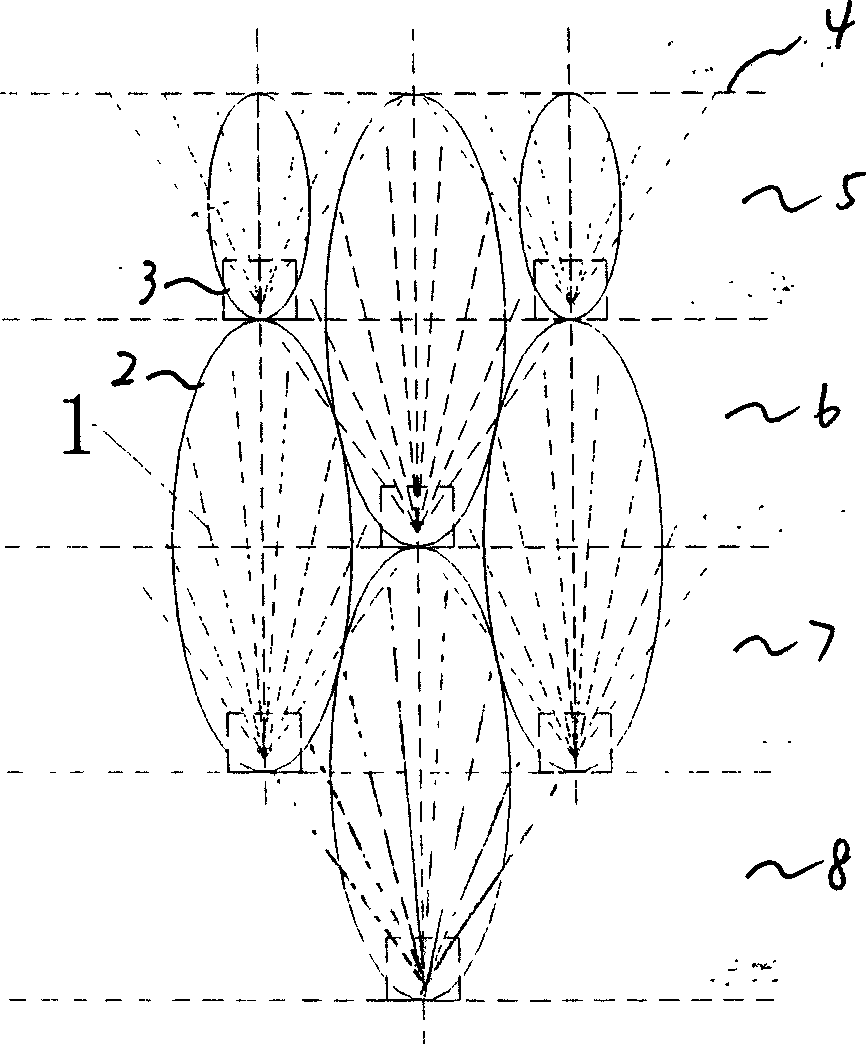

[0022] Embodiment 1: For a new mine, according to the occurrence conditions and the form of the ore body (the boundary line of the ore rock is about +186m), the stage height is 120m, the segment height is 12m, and the approach distance is 15m. Below the rock boundary line 4 are the first mining segment 5, the second segment 6, the third segment 7 and the fourth segment 8 in sequence. Blasthole 1 controls the range of the caving body in a fan shape, which is slightly larger than the elliptical discharge body 2 during mining and drawing. The original design floor elevation of the first mining section approach is +174m, and the second section approach floor elevation is +162m. And so on. According to the present invention, the floor elevation of the first mining section 5 approach is +162m (in order to reduce the difficulty of mining and cutting work, a cutting roadway can be designed on the floor elevation of the original first mining section +174m to pull the cutting groove), t...

Embodiment 2

[0023] Embodiment 2: For a certain production mine, according to the occurrence conditions and forms of the ore body, the stage height is 120m, the segment height is 15m, and the approach distance is 20m. As the mining work is carried out, when the mining work is carried out At -243m, the shape of the caving body (slightly larger than the emanating body 2) changes, and new caving bodies (slightly larger than the emanating body 2) are added in a large range between -243m and -228m, and the caving body (slightly larger than the emanating body 2) is added above -243m The height is about 10~12m. The original design normally arranges the mining approach at -243m (the floor elevation of the mining approach is -243m). The elevation of the road floor is -258m, which is the second subsection for the mining of newly added caving bodies (slightly larger than the discharge body 2), and the mining blast hole 1 is designed and constructed at -243m and -258m respectively. According to the p...

Embodiment 3

[0024] Embodiment 3: For a certain production mine, according to the occurrence conditions and forms of the ore body, the stage height is 120m, the segment height is 15m, and the approach distance is 15m. As the mining work is carried out, when the mining work is carried out The shape of the ore body changes at -198m, and caving bodies (slightly larger than discharge body 2) are added in a large range between -213m and -198m, and the height of caving bodies (slightly larger than discharge body 2) above -198m is about 2~3m . The original design normally arranges the mining approach at -213m (the floor elevation of the mining approach is -213m). The elevation of the road floor is -228m, which is the second subsection for the mining of newly added caving bodies (slightly larger than discharge body 2), and mining blastholes are designed and constructed at -213m and -228m respectively. According to the present invention, for large-scale newly-added caving bodies between -213m~-198...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com