Ultrahigh-power LED light and manufacturing method thereof

A technology of LED lights and ultra-high power, which is applied in cooling/heating devices of lighting devices, lighting and heating equipment, electrical components, etc. Small size, fast heat dissipation, and the effect of changing the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

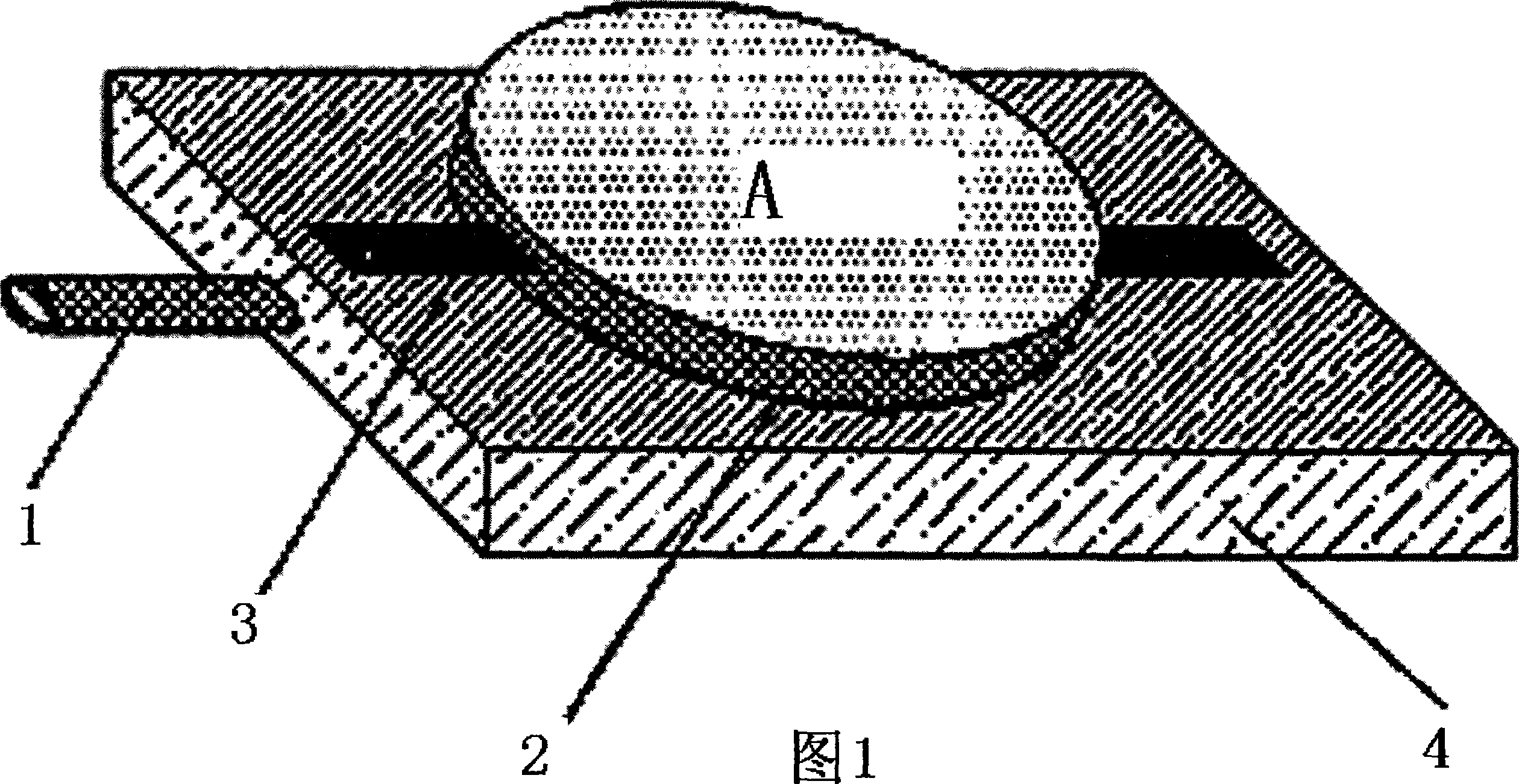

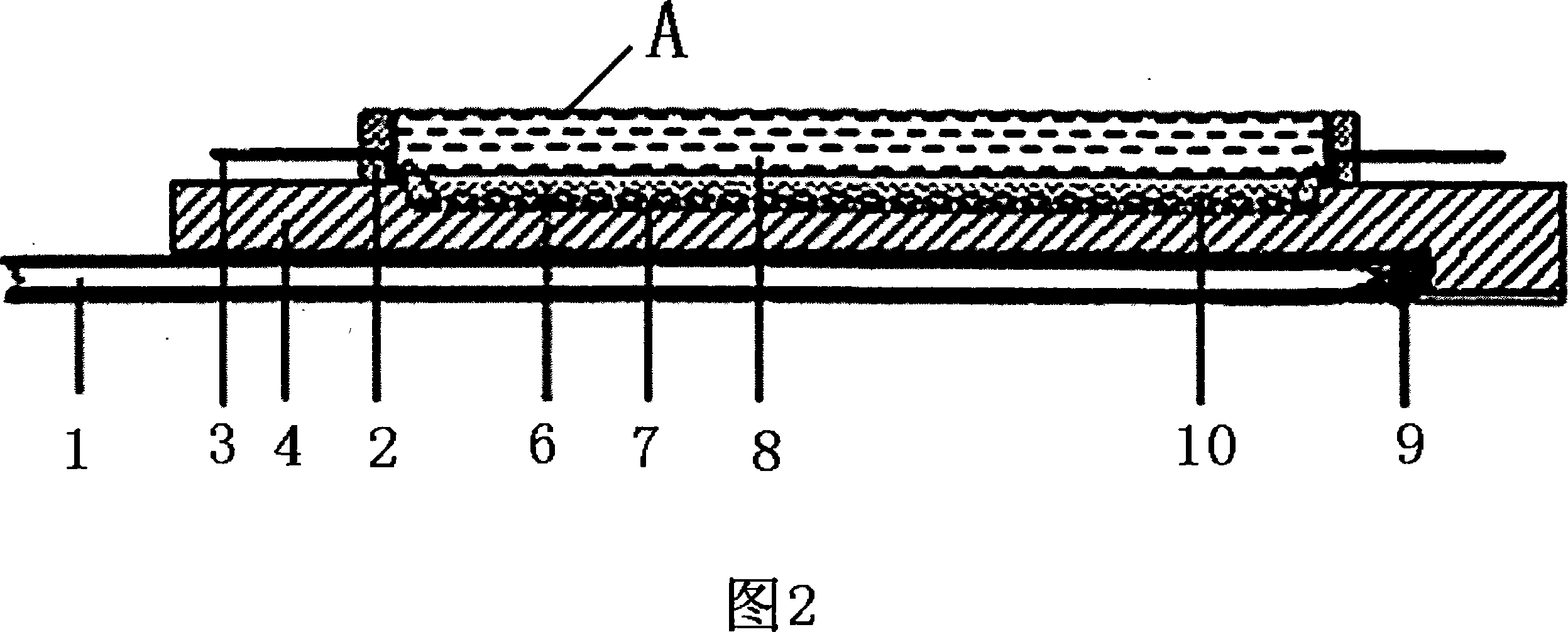

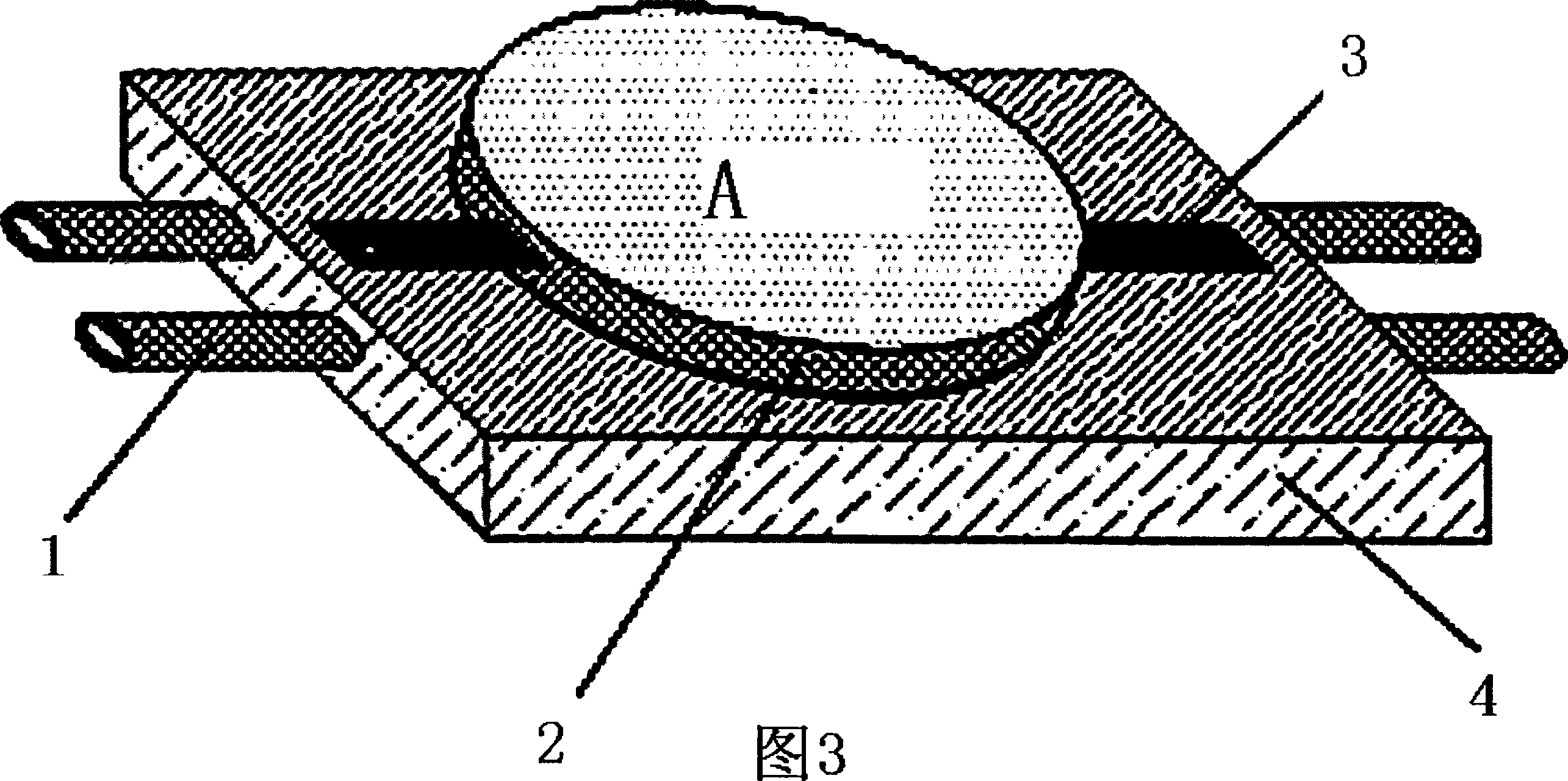

[0023] The manufacturing method of the ultra-high-power LED lamp of the present invention is completed by adopting a module-type encapsulation manufacturing method, and the cup body of the high-power LED lamp and the metal substrate form an integral structure. in:

[0024] 1. Heat pipe: an important component in the present invention, which can quickly transfer the heat generated when high-power LEDs are working. One end of the heat pipe is connected to a high-power LED, and the other end is connected to a lamp housing or other radiator. The heat generated by the LED is quickly transferred to the lamp housing or radiator through the heat pipe to achieve heat dissipation. According to the load (LED heating power) and the thermal migration capacity of the heat pipe itself, the heat pipe can be composed of a single group, a double group (Figure 1, Figure 5) or multiple groups (each group of heat pipes is composed of a single or multiple heat pipes), the tube Diameter size (∮3,∮5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com