Pipe shell type heat-exchanger

A shell-and-tube heat exchanger, heat exchange tube technology, applied in the direction of heat exchanger type, heat exchanger shell, indirect heat exchanger, etc., can solve the problem of large leakage, affecting the baffle effect, heat exchange effect and product performance and other issues, to achieve the effect of reducing leakage, reducing reserved design margin, and increasing rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

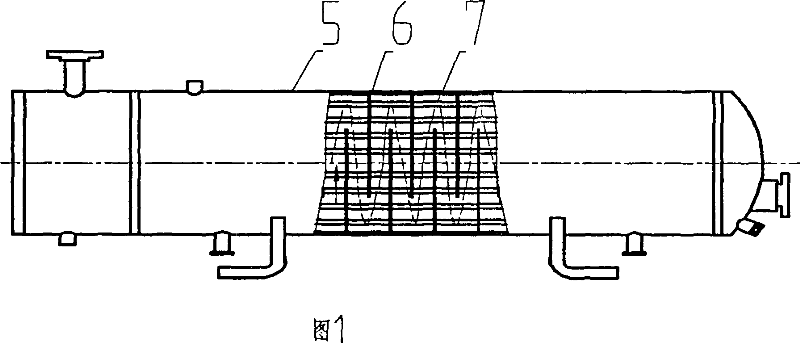

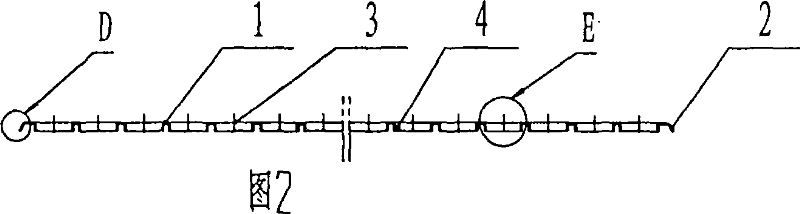

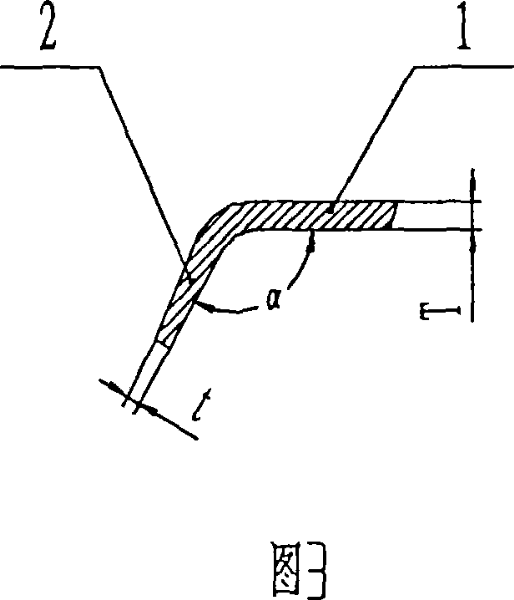

[0018] Embodiment: A shell-and-tube heat exchanger (see Fig. 1-Fig. 4), which is composed of a casing 5, a baffle 6 connected inside the casing 5, and a heat exchange tube 7, and the baffle 6 has a plate body 1. The plate body 1 is made of thin metal plate, and the thickness T of the plate body 1≤20mm. The periphery of the plate body 1 is provided with a folded edge 2, the folded edge 2 is integrated with the plate body 1, the thickness of the folded edge 2 is ≤ 20mm, and the angle α between the folded edge 2 and the plate body 1 is 90°~270° °, the edge thickness t of the folded edge 2 is less than or equal to 20mm. The plate body 1 is uniformly provided with a baffle hole 3, the inner diameter φd of the baffle hole 3 is 5-57mm, and the periphery of the baffle hole 3 is provided with a flange 4, which is integrated with the plate body 1, and The thickness of the edge 4 is ≤20mm, and the height h of the flange 4 is ≤50mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com