Dry friction lining for the friction device of a dry clutch for a motor vehicle, a dry friction device, a dry friction clutch and a mould for moulding a friction lining

A dry clutch, friction lining technology, applied in the direction of friction linings, brake components, brake types, etc., can solve problems such as long running-in stages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

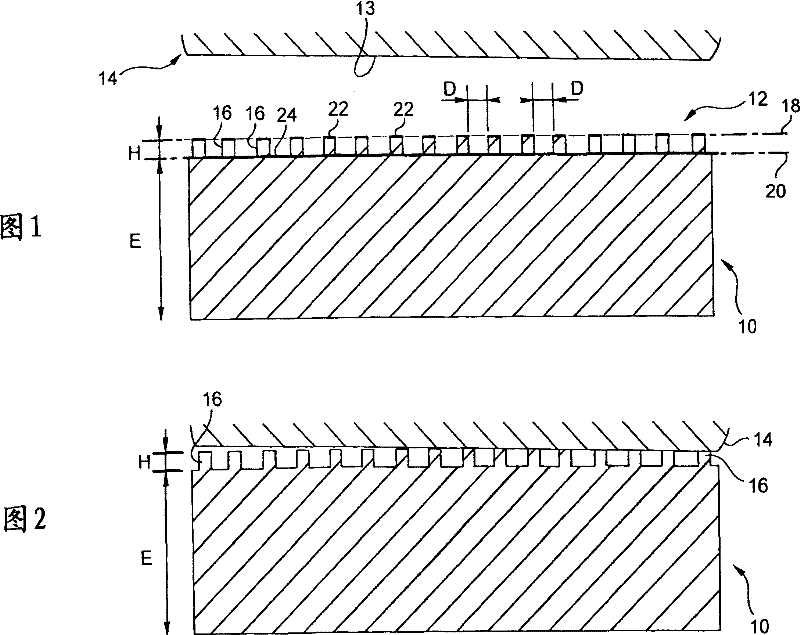

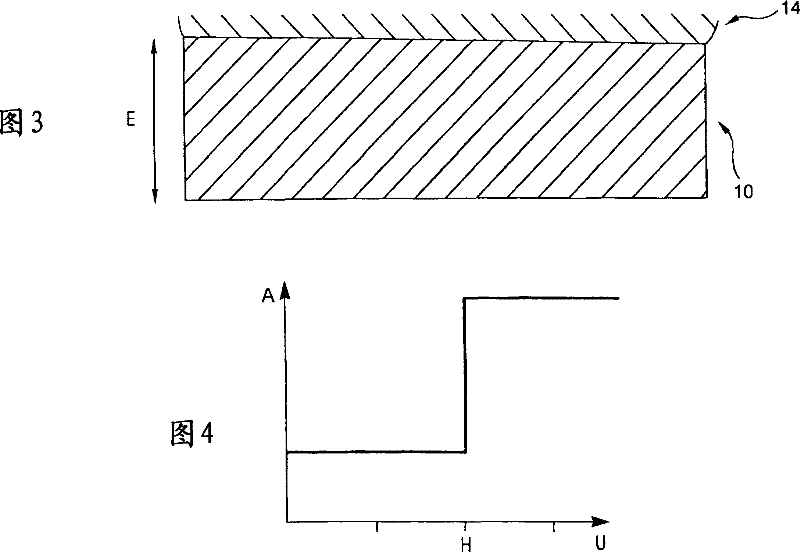

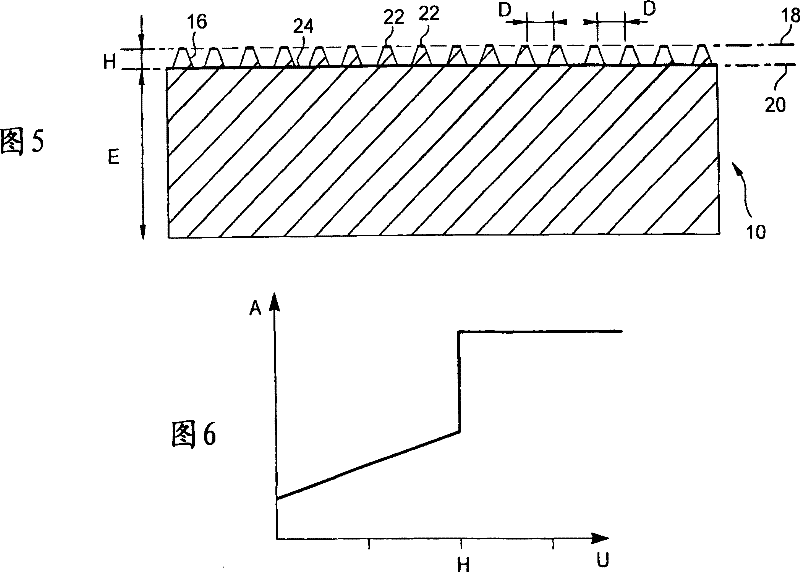

[0037] figure 1 A dry friction lining according to the first embodiment of the present invention is shown. Said lining is indicated with the general numeral 10 and is intended to be fitted to a friction device of a motor vehicle clutch.

[0038] Said friction lining 10 is provided with a friction surface 12 for cooperating with a complementary friction surface 13 of a pressure or reaction plate 14 of said clutch in order to rotationally connect said friction means with said plate 14 clutch mechanism.

[0039] Preferably, the dry friction device includes two movable supports, the supports are connected to each other through axial damping components, and each support supports a friction lining 10, and the lining is respectively connected to the The pressure plate and the reaction plate cooperate.

[0040] figure 1 A slight parallelism defect between the friction lining 10 and the plate 14 is shown, which may exist in some cases.

[0041] In order to reduce the running-in ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com