Device and process of measuring surface smoothness of double plate in fuel cell

A surface smoothness and fuel cell technology, applied in the direction of measuring devices, electromagnetic measuring devices, measuring electricity, etc., can solve the problems of inaccuracy and complicated detection methods, and achieve the effect of simple device, easy operation and high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

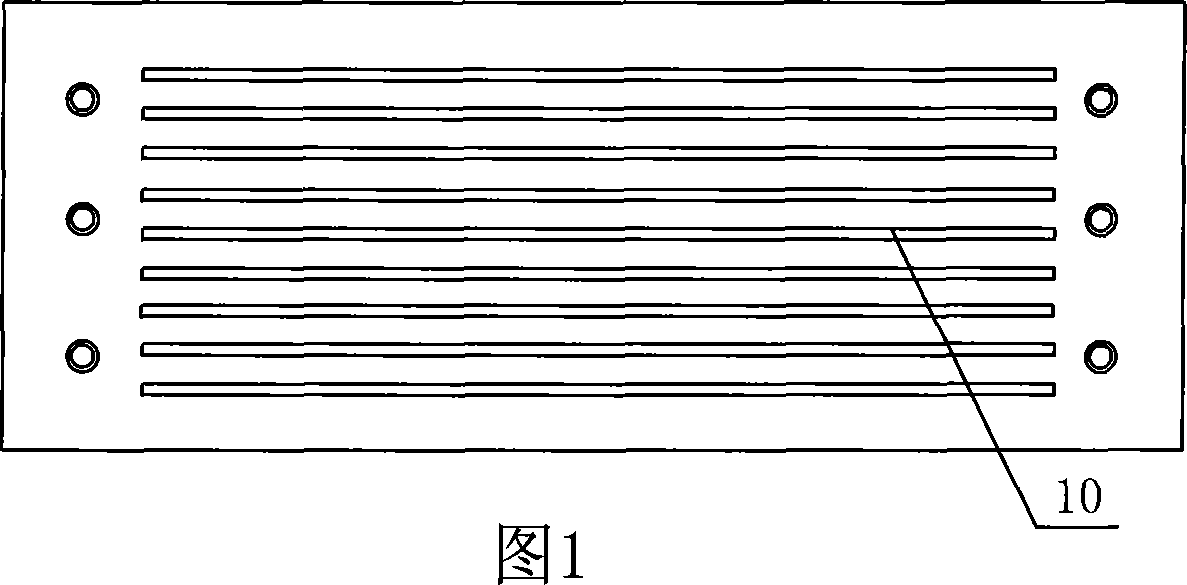

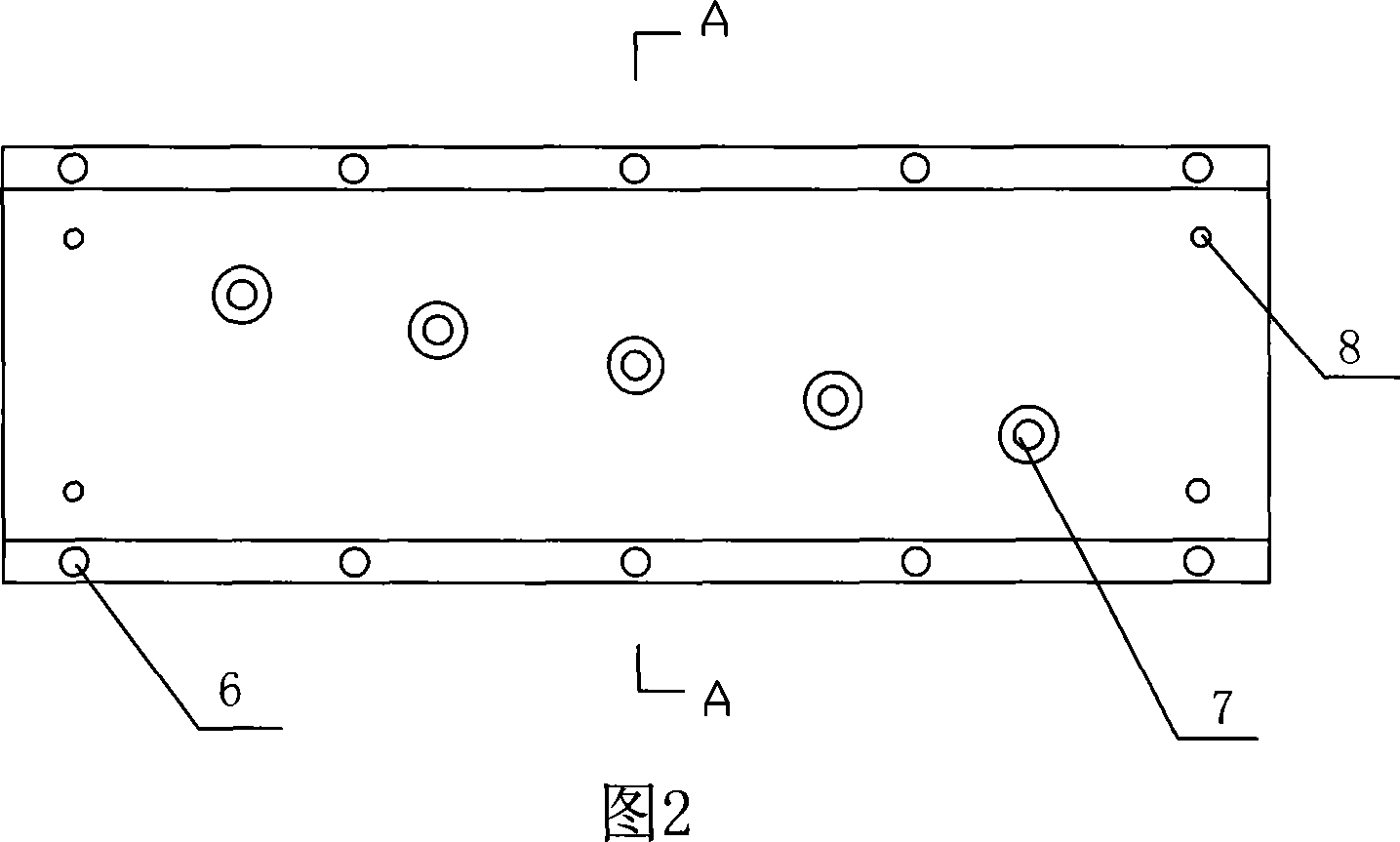

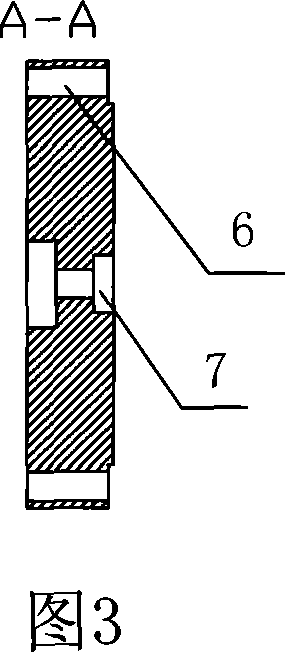

[0029] As shown in Figures 1 to 5, the utility model designs a device for detecting the flatness of the sheet-shaped conductor surface according to the idea of testing contact resistance. , the material of the test end plate 1 is insulating material, and the flatness of the test end plate 1 and end plate 2 should be within 0.03mm, that is, the difference between the concave and convex points on the surface of the plate and the thickness should not exceed 0.03mm at most. A conductive test block 3 is embedded on the test end plate 1. The material of the test block 3 can be metal or precious metal plating. The surface of the test block 3, the contact end of the electrode plate 4 and the diffusion layer coincides with the surface of the test end plate 3. And the flatness is consistent, it is the lead-in end of electricity, that is, the current is introduced into the pole plate 4, and the test block 3, the diffusion layer, and the pole plate 4 form an electric test circuit. The o...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap