Drawing and extruding section bar for metal reinforced glass fiber reinforced plastic door and window and its producing method

A pultrusion profile and metal reinforcement technology, applied in the direction of window/door frame, leaf frame, etc., can solve the problems of weak transverse strength of FRP profiles, high cost, insufficient holding force of screw fasteners, etc., and achieve simplified assembly and The effect of installation process, long service life and low processing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

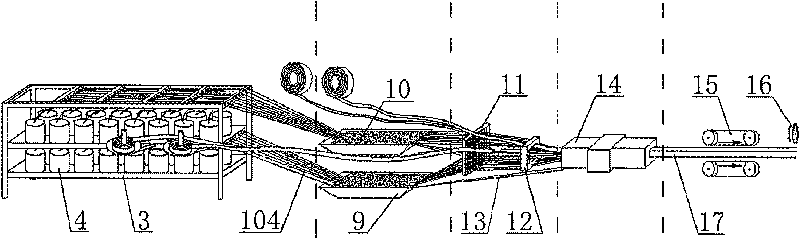

Method used

Image

Examples

Embodiment 1

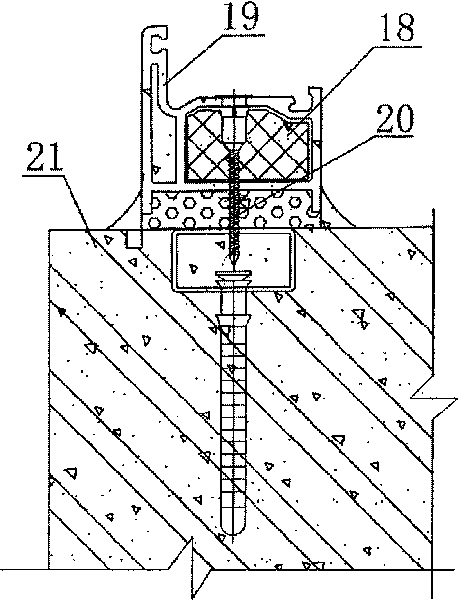

[0041] Embodiment one sees Figure 6 , 8 As shown, this pultrusion profile 1 with inner partition is formed by three longitudinal thin walls and two transverse thin walls to form an inner partition 106 and a slender hollow rod shape with two cavities 108. There is a groove 107 on the outer surface of the wall, and it is characterized in that: there is a layer of metal strip 105 inside each of the two transverse thin walls, and the cross section of the above thin walls has fiber felt 102, fiber cloth 103, and fiber bundles in sequence from outside to inside. 104. The metal belt 105 and the fiber cloth 103. The above layers are impregnated and solidified with a resin mixture.

[0042] see Figure 7 , the inner partition 106 is sequentially impregnated with a resin mixture by the mesh mat 101, the fiber bundle 104, and the mesh mat 101, and cured as a whole.

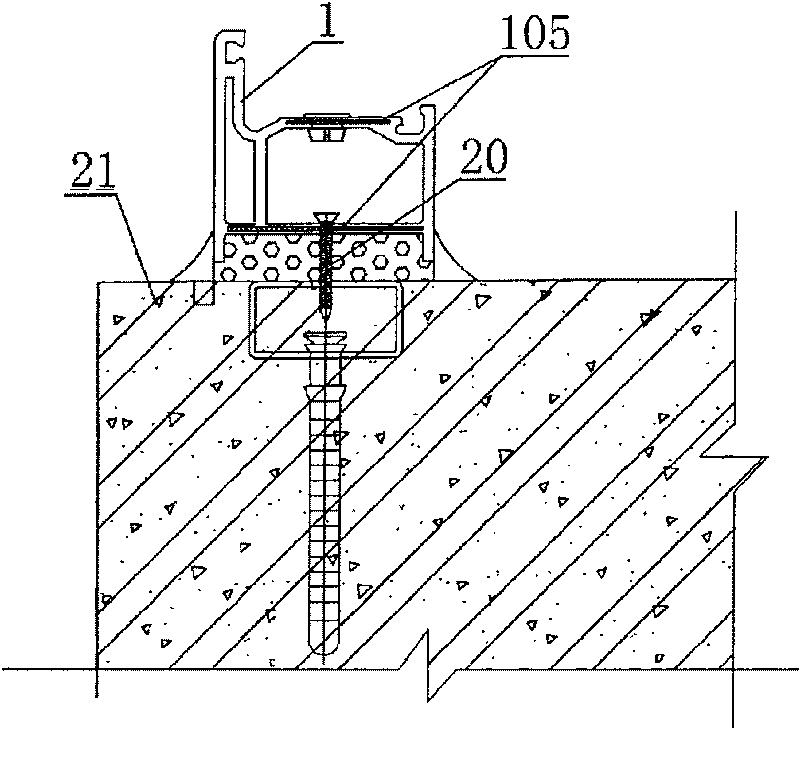

Embodiment 2

[0043] Embodiment two see Figure 9-10 As shown, this pultrusion profile 2 without internal partition is surrounded by two longitudinal thin walls and two transverse thin walls into a shape of a slender hollow rod with a cavity 108, and the outer surface of the above thin walls is concave. The groove 107 is characterized in that: there is a layer of metal strip 105 inside each of the two transverse thin walls, and the cross-section of the above thin walls has fiber felt 102, fiber cloth 103, and fiber mats 103 uniformly arranged along the lengthwise direction from the outside to the inside. Bundle 104, metal belt 105, fiber cloth 103, the above layers are impregnated with resin mixture and cured as one.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com