Series fan and its flow guide structure

A tandem, fan technology, applied in non-variable-capacity pumps, components of pumping devices for elastic fluids, machines/engines, etc., can solve the problems of reduction, flow field disorder, low fan blade work efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

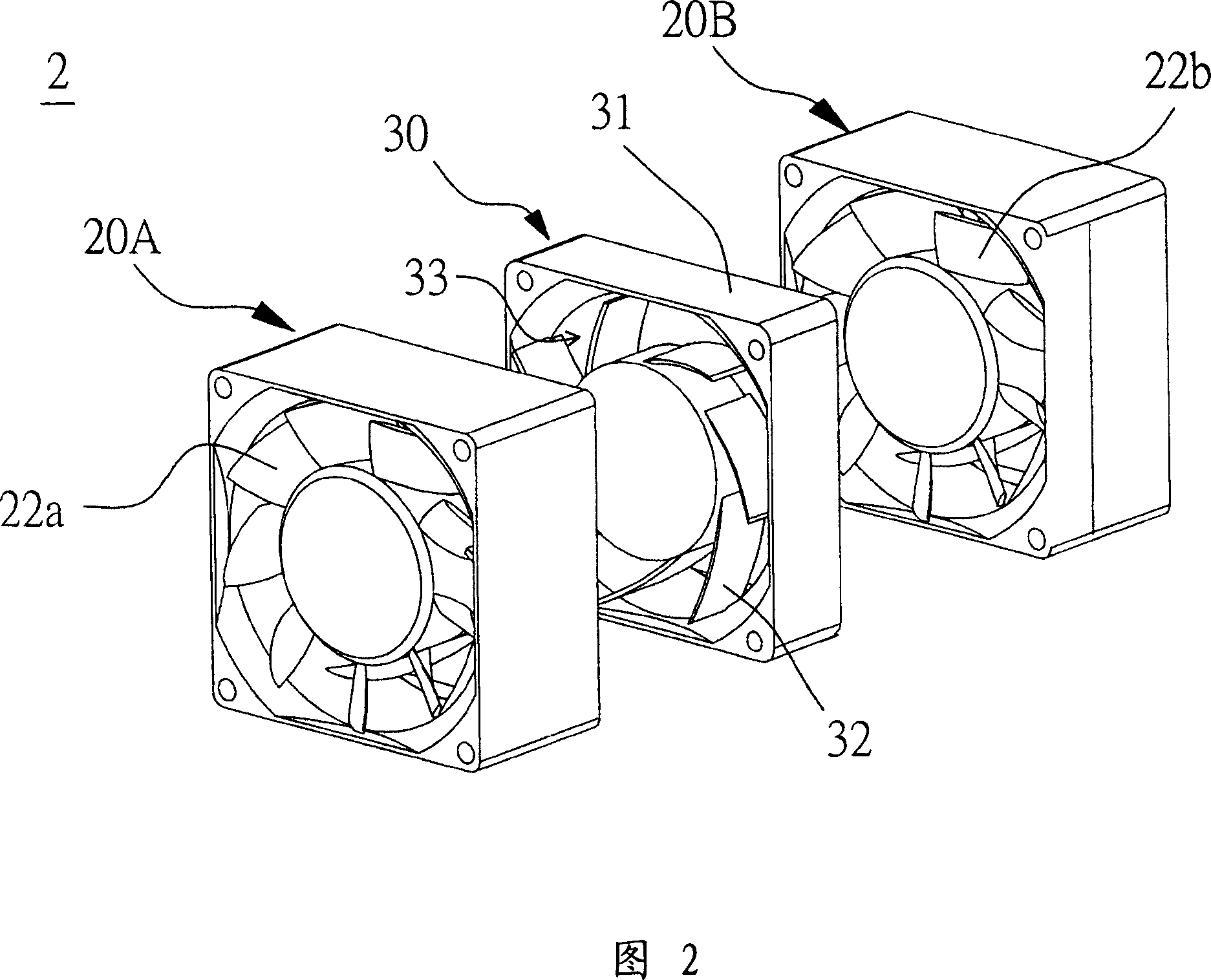

[0036] Please refer to FIG. 2 , which is a schematic diagram of a serial fan according to a preferred embodiment of the present invention. The serial fan 2 at least includes a first fan 20A, a second fan 20B and a flow guiding structure 30 . The second fan 20B is connected in series with the first fan 20A, and the flow guiding structure 30 is disposed between the first fan 20A and the second fan 20B. The air guide structure 30 is used to guide the air flow from the first fan 20A, and the air flow angle when entering the second fan 20B is parallel to the axial direction, so as to increase the air volume and air pressure of the serial fan 2 . The first fan 20A and the second fan 20B are axial flow fans, and the flow guide structure 30 and the serial fan 2 are independent, and can be combined or separated from each other by, for example, free clamping, locking or bonding.

[0037] Please refer to Figure 3A and Figure 3B at the same time, Figure 3A is a schematic cross-sectional ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com