Quartz resonator, quartz resonator package, and quartz oscillator

A technology of quartz vibrator and quartz plate, applied in power oscillators, electrical components, impedance networks, etc., can solve problems such as different uses, purposes, large specific gravity, and high rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

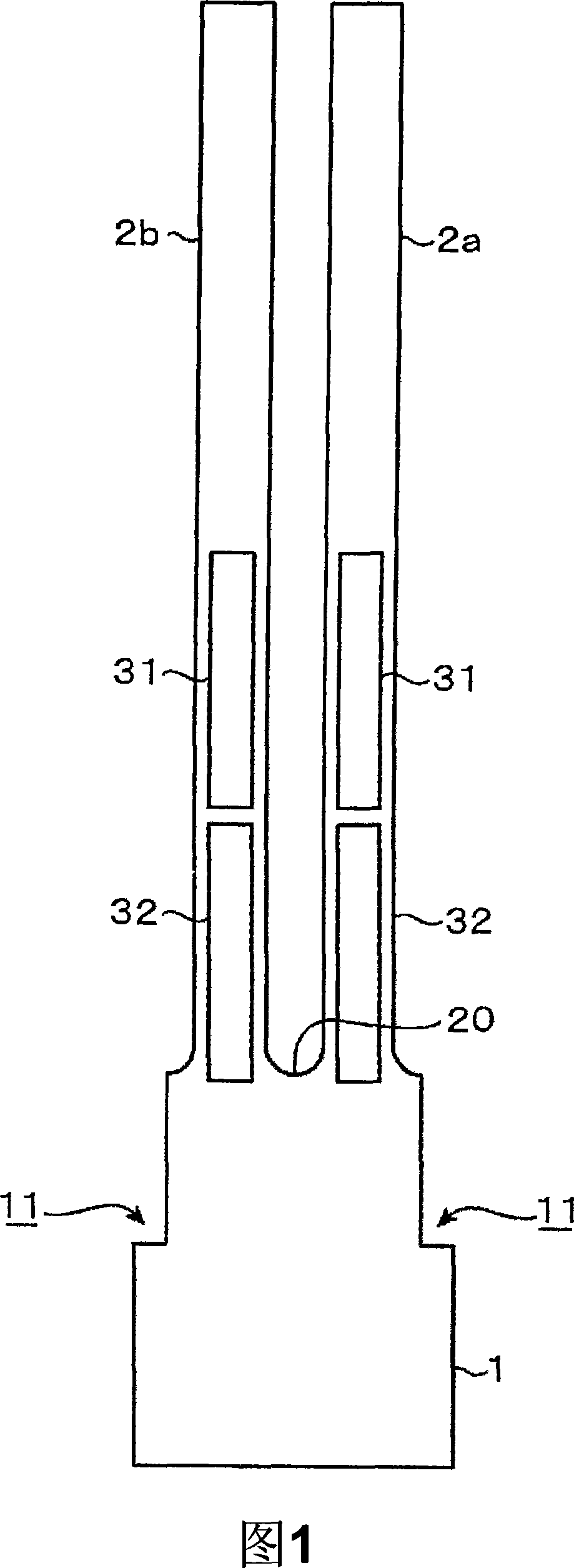

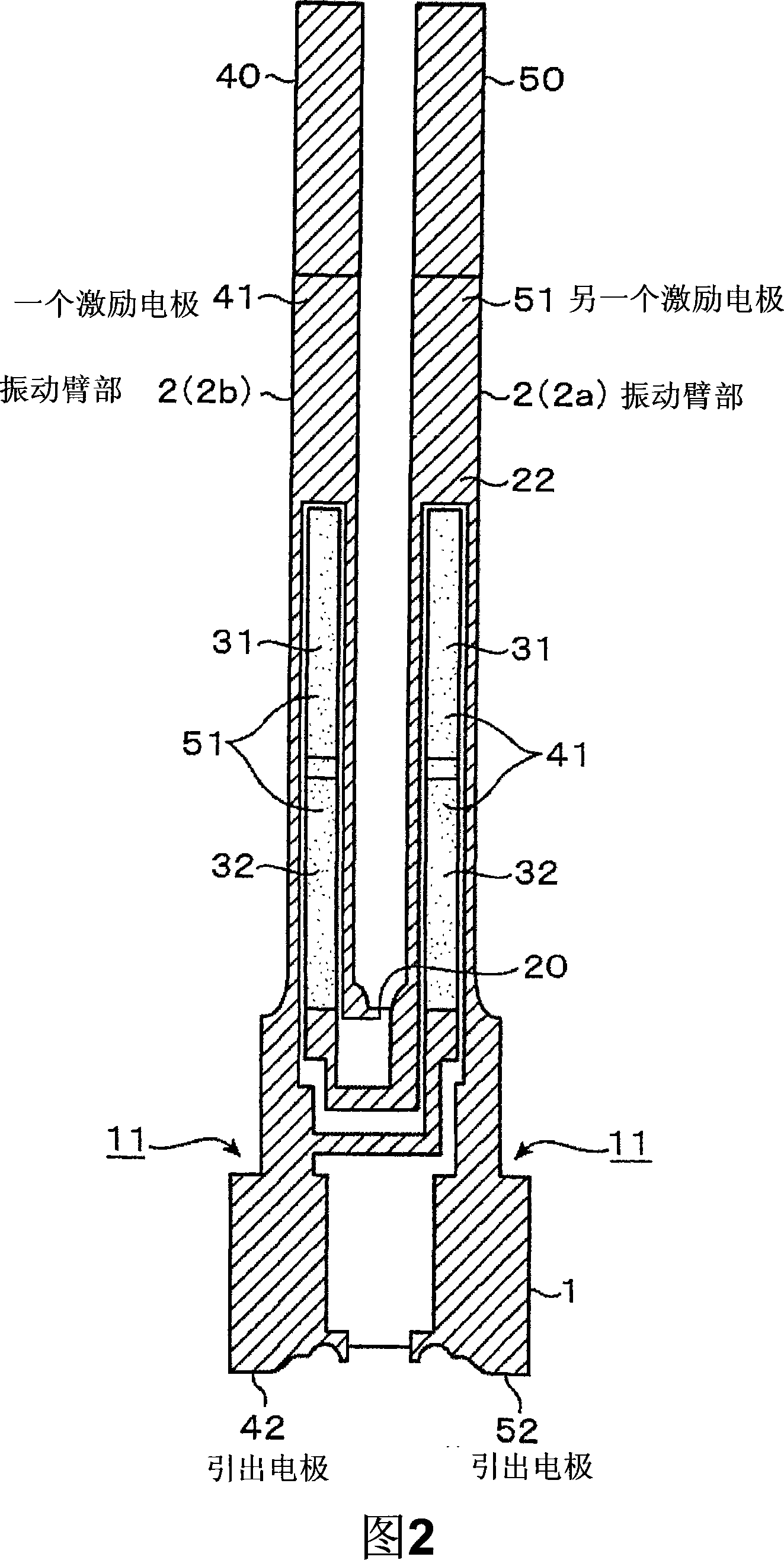

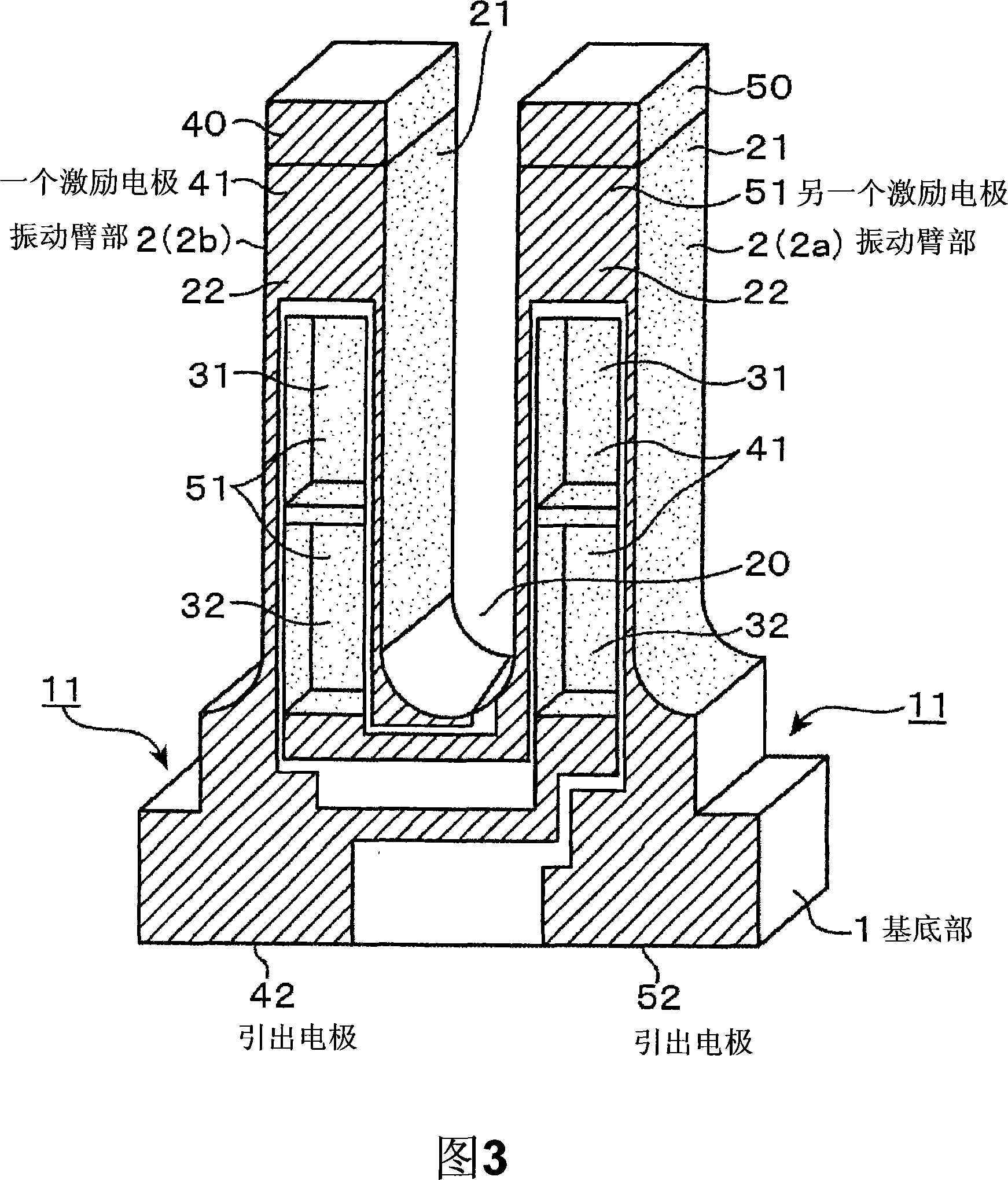

[0020] The tuning-fork-type crystal resonator shown in FIG. 1 described in the background art can also be applied to the crystal resonator of this embodiment. The shape of this quartz vibrator can be described in detail as follows: the quartz vibrator body (quartz plate) has: a substantially square base portion 1 having a notch 11 cut into a rectangle at the upper side of both sides, and a Two (a pair) of vibrating arm parts 2 (2a, 2b) extend in parallel at a distance from each other on the upper end side, and the overall shape is a tuning fork-shaped quartz plate. In addition, on the main surfaces of the front side and the back side of the vibrating arm parts 2 (2a, 2b), respectively, there are formed, from the bottom end portion of these vibrating arm parts 2 (2a, 2b) toward the front end side, respectively formed in the longitudinal direction. The groove portions 31, 32 are bisected. The grooves 31 and 32 function to increase the strength of the electric field formed in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com