Positioning conveyor

A technology of conveyor belts and conveyor belts, which is applied in the direction of conveyors, conveyor objects, packaged food, etc., and can solve problems such as congestion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

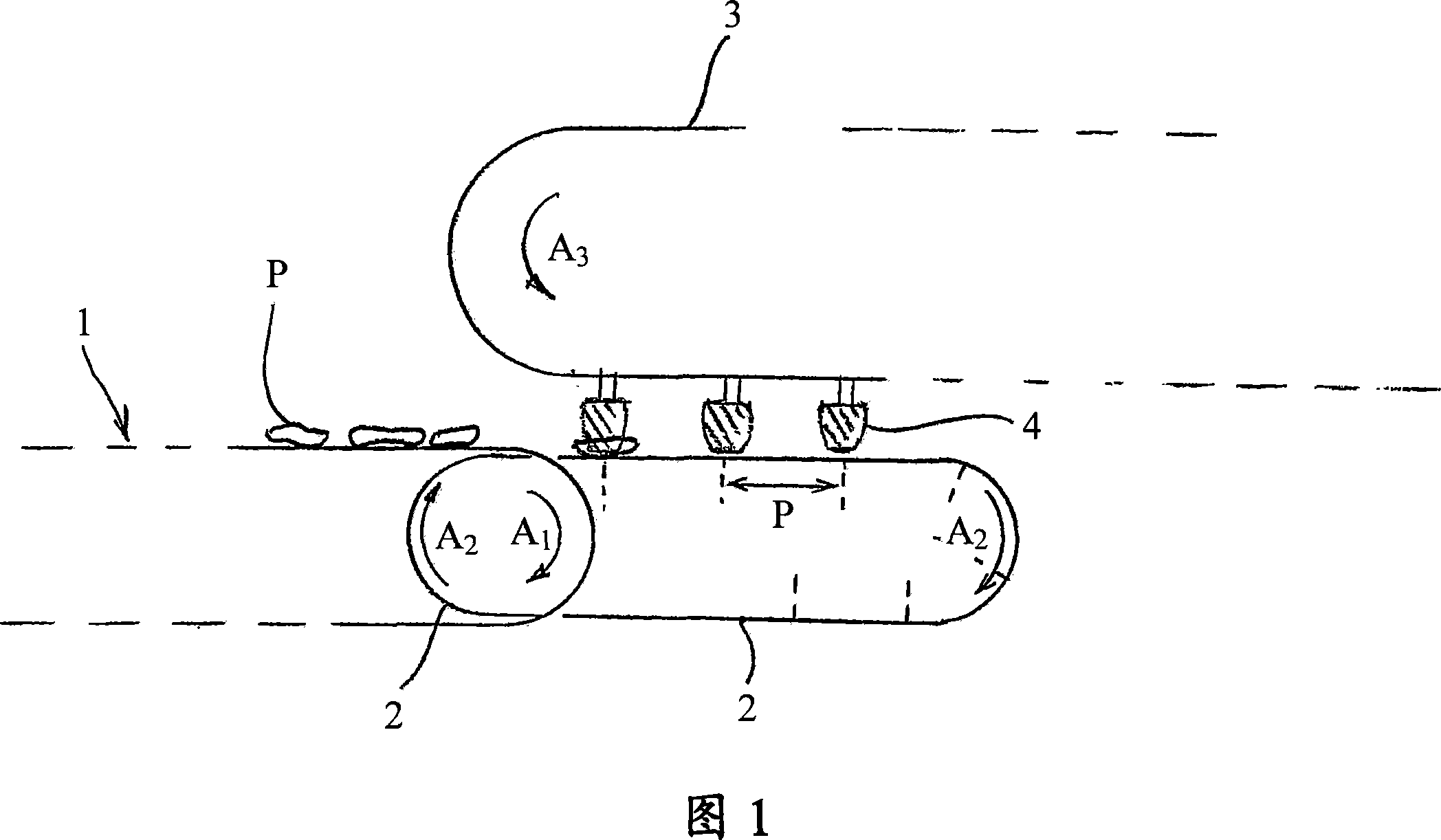

[0010] In the following, the invention will be described in more detail with reference to FIG. 1 in which the device is schematically shown.

[0011] In FIG. 1 , a number of elongated objects or products P are supplied on an endless supply conveyor 1 . The direction of movement of the feed conveyor is indicated by arrow A1. The feed conveyor belt is preferably a so-called V-channel conveyor belt with two endless flat belts formed by V-channels. For this V-shaped channel, when the products or objects are supplied to the V-shaped channel, they are arranged not only one behind the other, but also one above the other, in a single form, that is, lined up, one after the other. These belts can also move at different speeds so that the product or object can also be rotated to some extent by friction with the belts. The position of the products P in turn at the end of the feed conveyor 1 is shown schematically. For example, the drive of the end wheels is not shown.

[0012] Followi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com