Paper transporting felt and press apparatus of paper machine having the paper transporting felt

A paper conveying and paper machine technology, applied in the field of press equipment, can solve the problems of large size, large irregularity, undesirable dehydration characteristics of wet paper, etc., and achieve the effect of optimizing characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] A detailed description will be given below of embodiments according to the present invention with reference to the accompanying drawings.

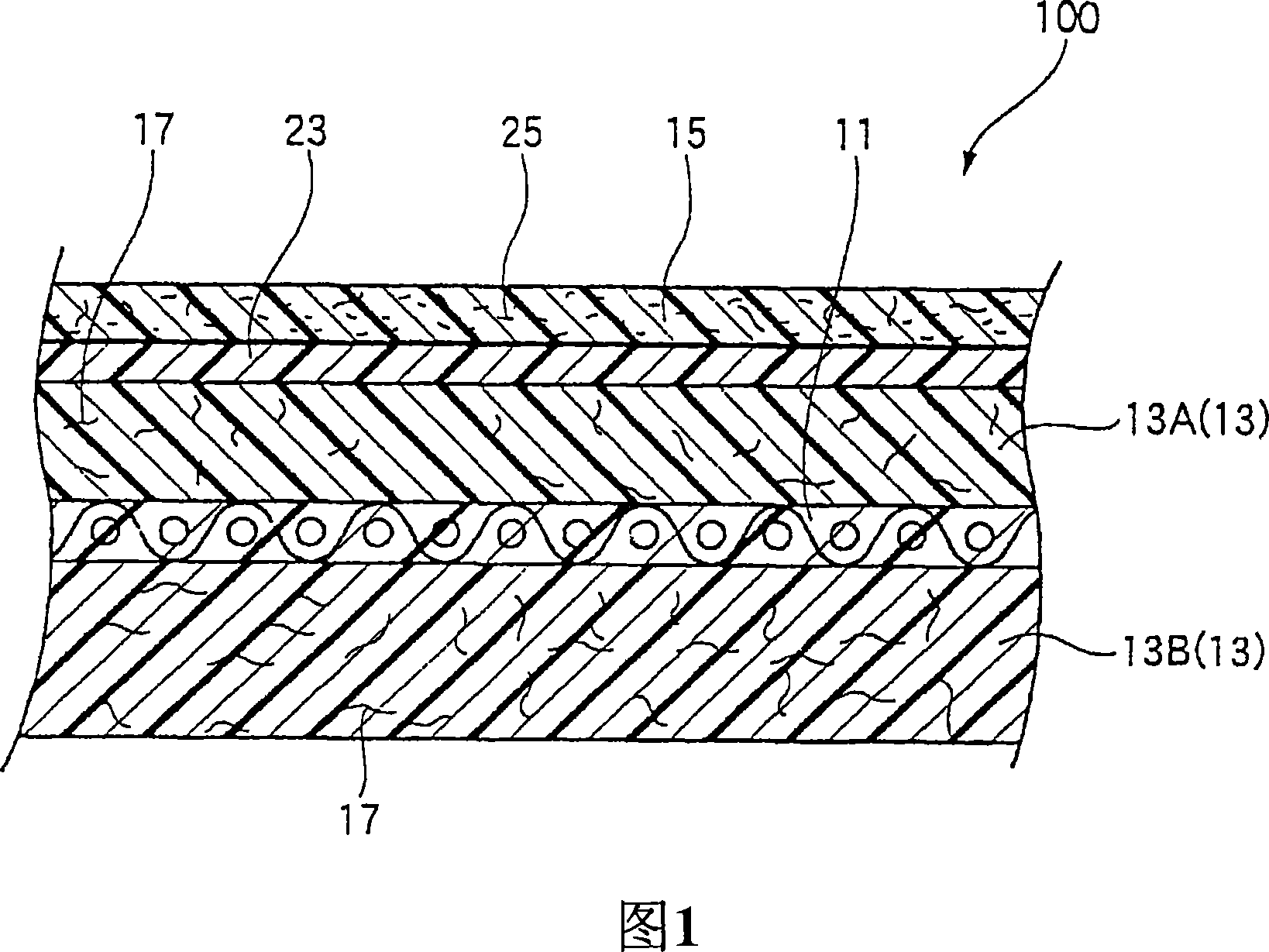

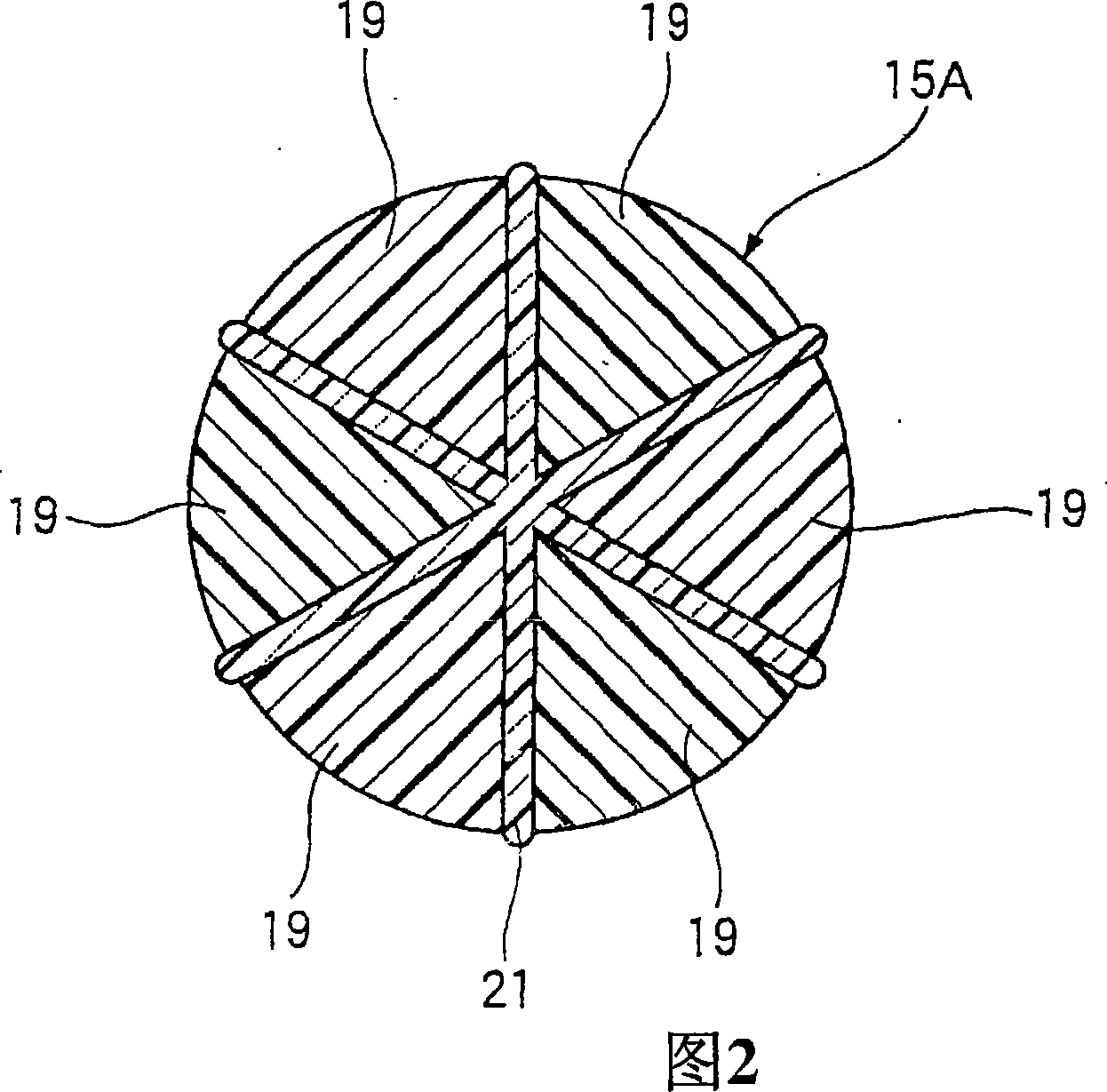

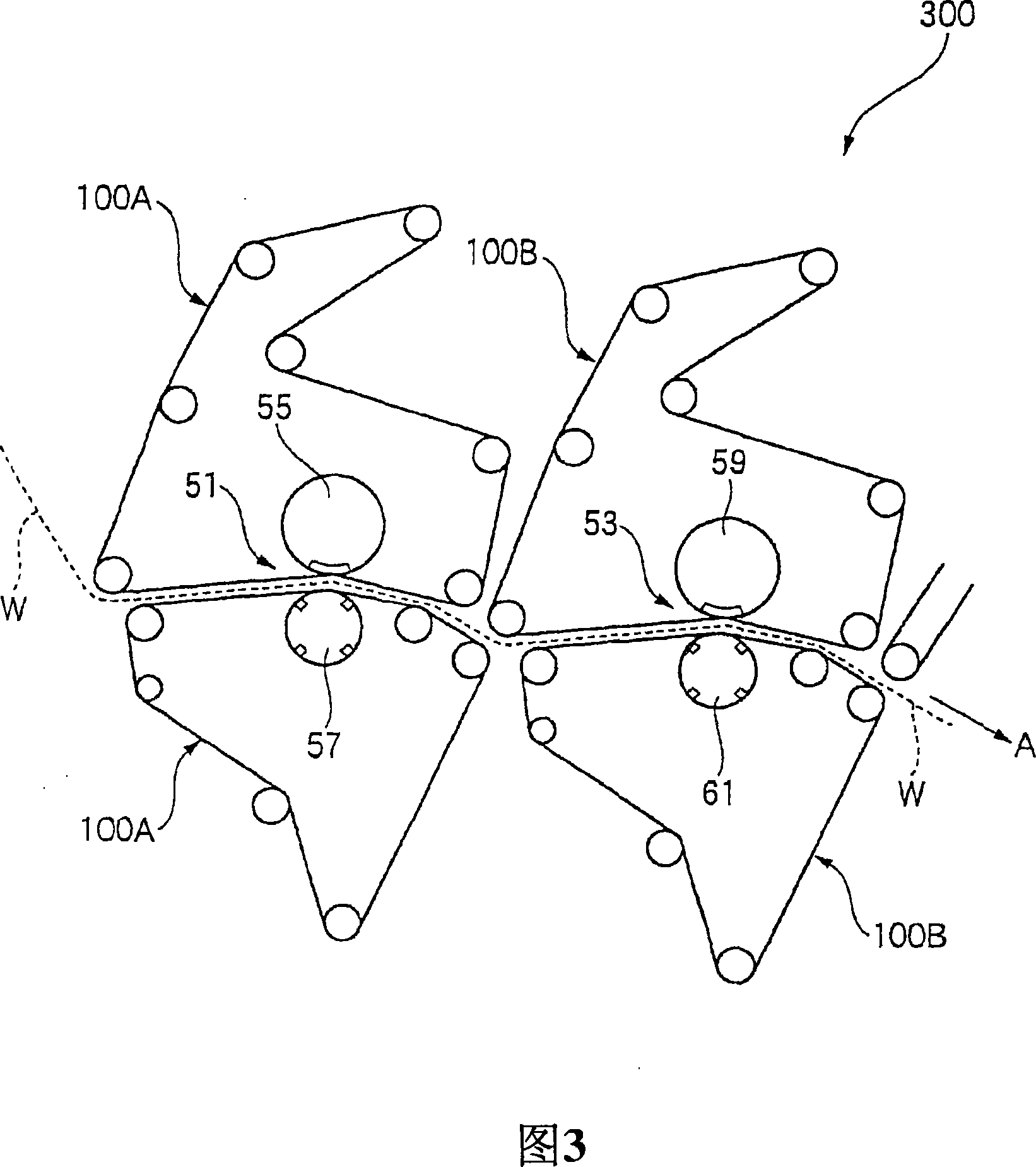

[0056] Fig. 1 is a vertical sectional view of an embodiment of a paper conveying felt 100 according to the present invention. FIG. 2 is an enlarged cross-sectional view of detached fibers used to form the wet paper contacting fibrous layer of the paper transport felt of FIG. 1. FIG. Fig. 3 is a plan view showing a schematic structure of an embodiment of a press for a paper machine according to the present invention.

[0057] As shown in FIG. 1 , the paper conveying felt 100 has a base layer 11 , a batt layer 13 (a first batt layer 13A and a second batt layer 13B), a hydrophilic nonwoven fabric layer 23 , and a wet paper contact fiber layer 15 . More specifically, the first batt layer 13A is formed on the wet paper side surface of the base layer 11, and the second batt layer 13B is formed on the press side surface of the base layer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com