Power driven bending endoscope with detachable insertion portion

A technology of insertion part and detachable type, which is applied in the direction of telescope, surgery, instrument, etc., and can solve the problems of large power transmission loss and troublesome disassembly and assembly of endoscopes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

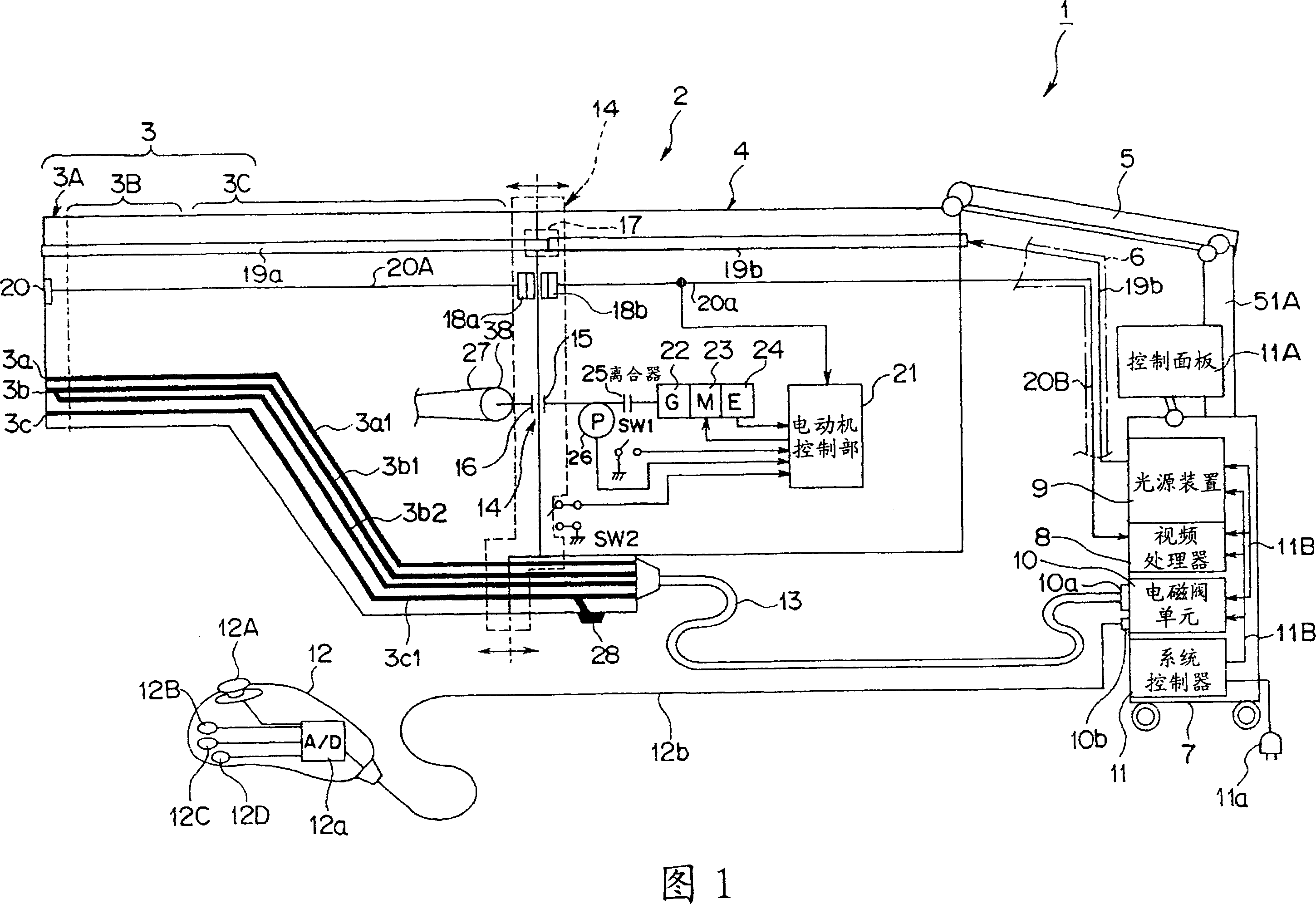

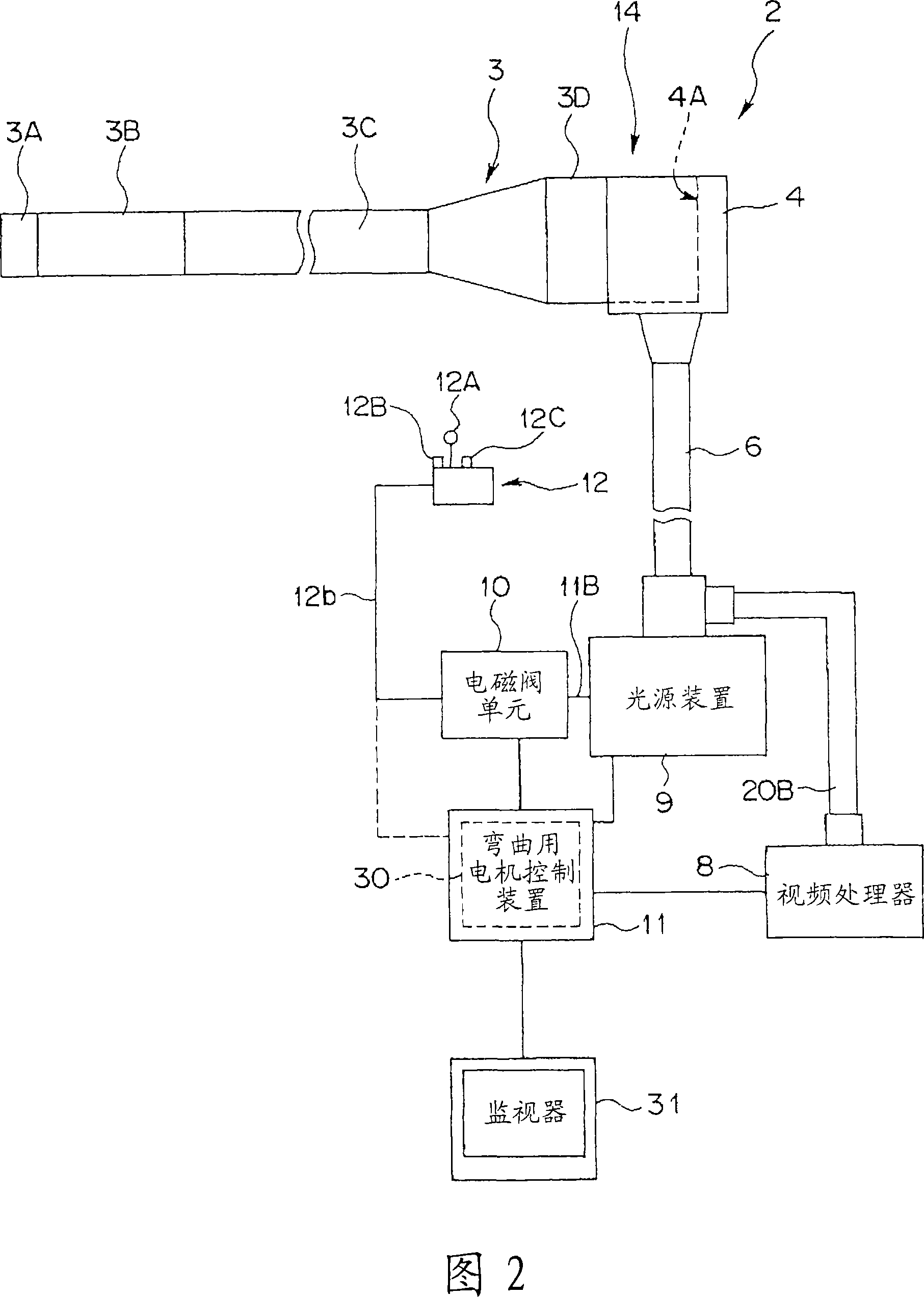

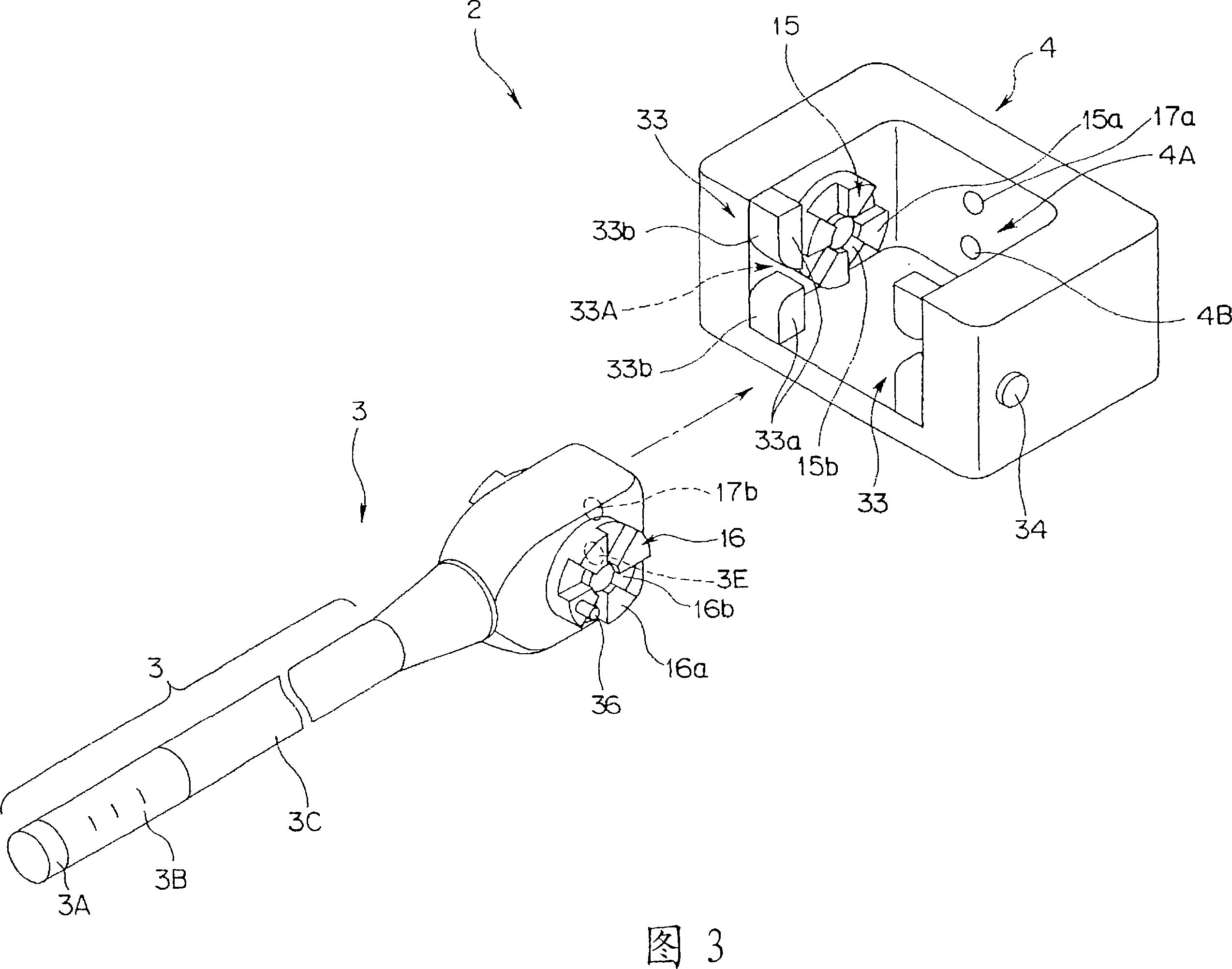

[0029] Embodiments of the present invention will be described below with reference to the drawings.

[0030] First, a first embodiment of the present invention will be described with reference to FIGS. 1 to 5 .

[0031] As shown in FIGS. 1 and 2 , an endoscope system 1 is composed of an insertion portion detachable electric bending endoscope (hereinafter simply referred to as an endoscope) 2 and its external devices.

[0032] The endoscope 2 mainly includes an insertion portion main body 3 and a motor unit 4 . The motor unit 4 is a power unit. The motor unit 4 and the insertion part main body 3 are detachably configured as described later.

[0033] The insertion part main body 3 is provided with a front end rigid part 3A, a bending part 3B, a flexible tube part 3C, an insertion part engaging part 3D and the like in order from the front end side. For example, the imaging element 20 is incorporated in the distal rigid portion 3A. The bending portion 3B performs a bending ope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com