Hexagonal wrench used for treating chamfering screw

A hexagonal wrench and screw technology, applied in the field of hexagonal wrench, can solve the problems of inability to effectively withdraw the screw, inconvenient handling, etc., and achieve the effects of enhancing convenience, easy operation, and improving the clamping effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below in conjunction with the accompanying drawings. It should be noted that the following descriptions are only preferred embodiments of the present invention, and are not intended to limit the scope of protection of the present invention. Therefore, any modifications or changes based on the spirit of the present invention should still be included in the present invention. within the scope of the invention.

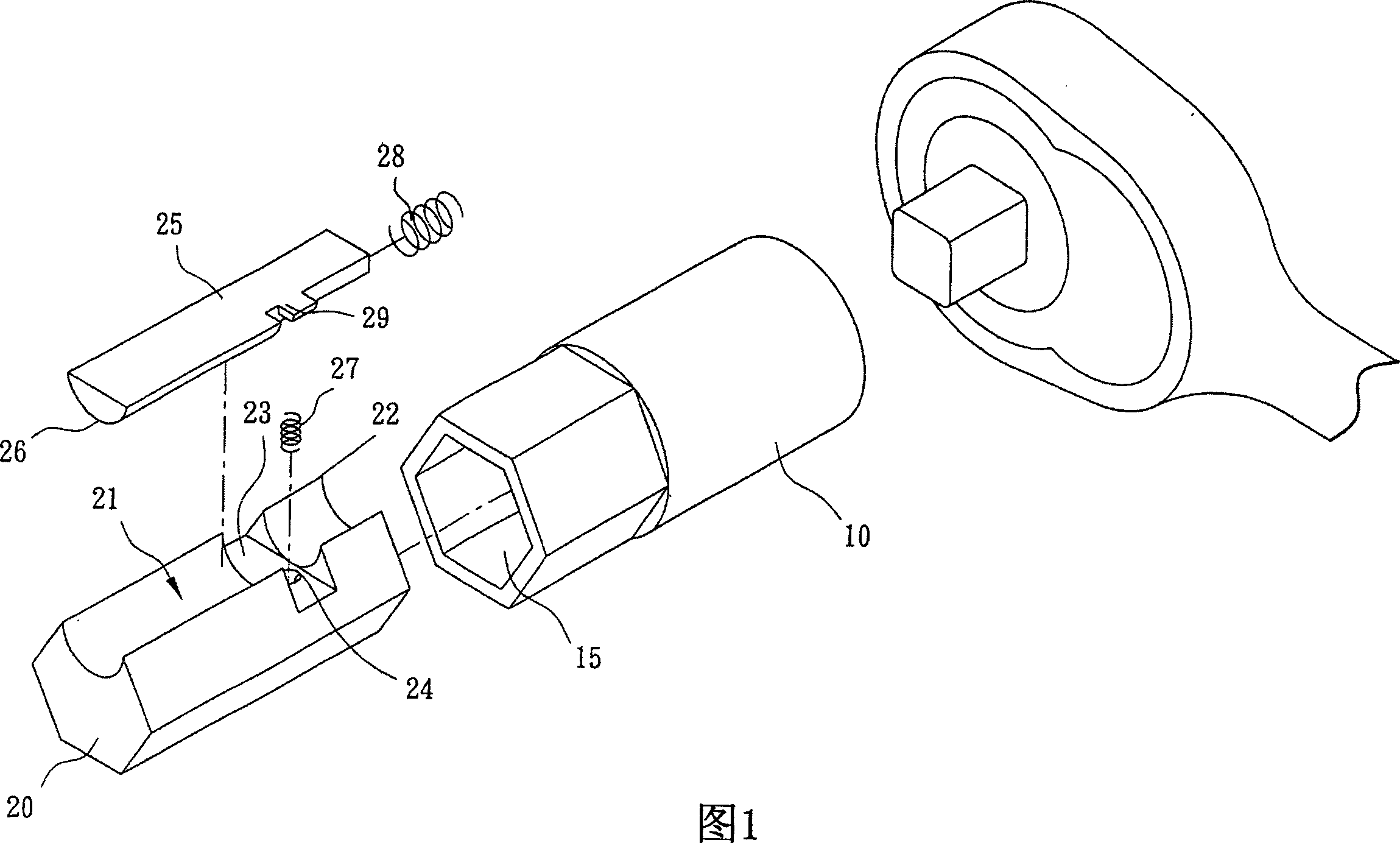

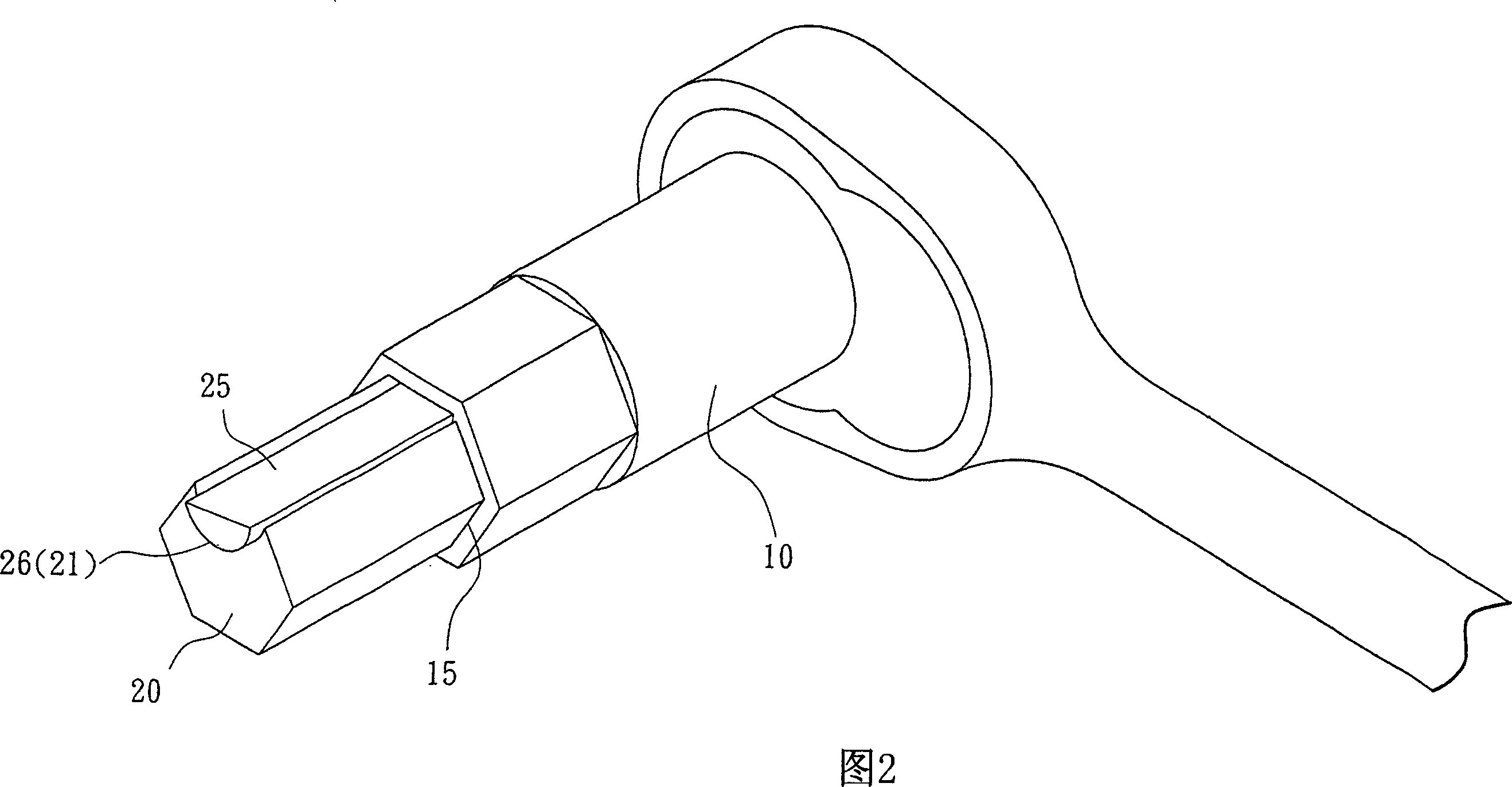

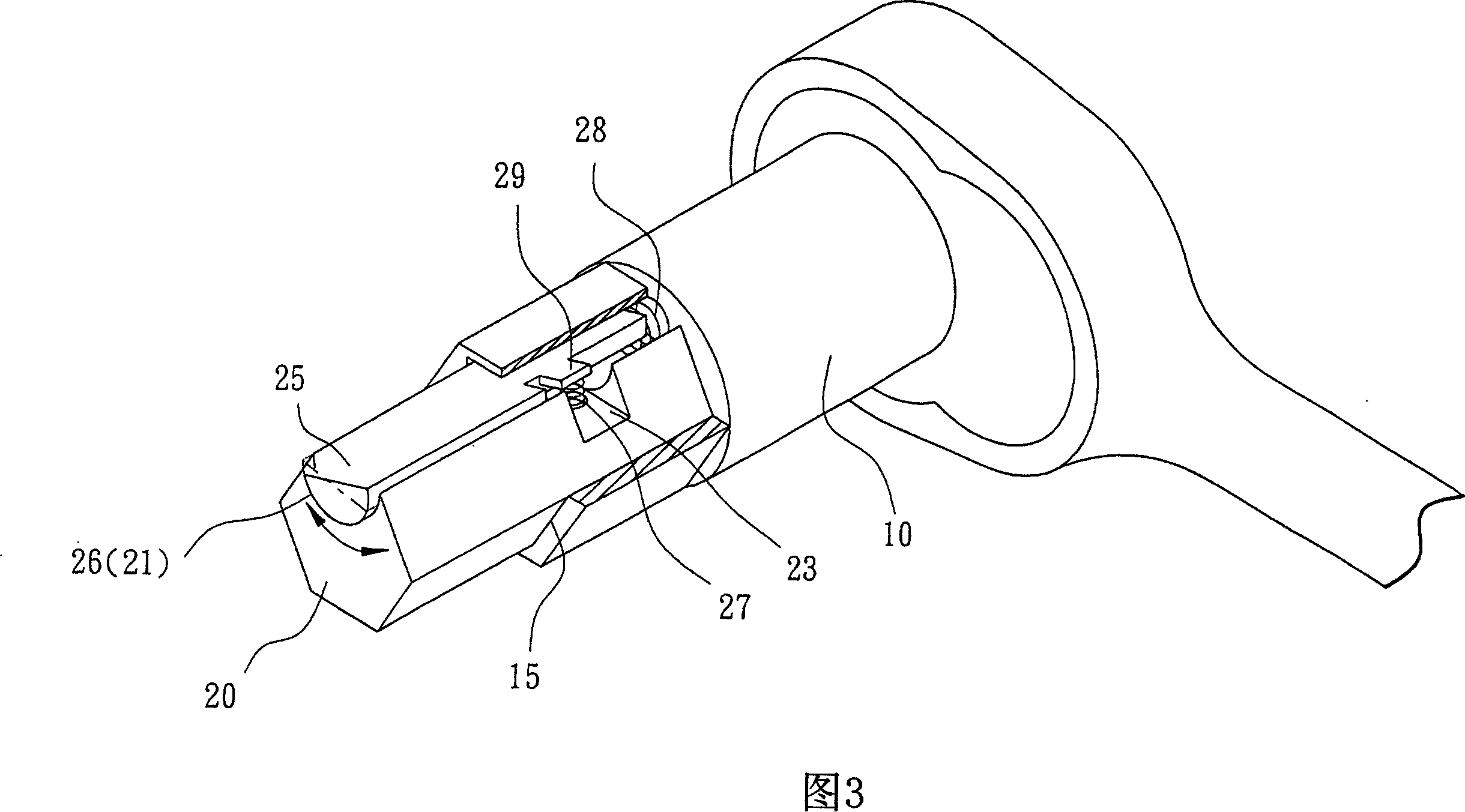

[0016] The present invention is a hexagonal wrench that can handle chamfered screws, please refer to Figure 1 and Figure 2, it is composed of a sleeve 10 and a sleeve shaft 20, wherein the sleeve 10 can be used by the user to use a ratchet Type socket wrench or open-ended wrench or ring wrench etc., the present invention is mainly described with the ratchet type socket wrench as an embodiment.

[0017] Regarding the detailed structure of the preferred embodiment of the present invention, as shown in Fig. 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com