Device and method for zinc-plating steel wire for colored coating, and the zinc-plating steel wire

A galvanized steel wire, glossy technology, applied in chemical instruments and methods, coatings, hot dip plating processes, etc. Difficult to control and other problems to achieve the effect of improving product quality, improving coloring and coating process, and easy coloring and coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the drawings.

[0033] If it is considered that a detailed description of a known function or structure related to the present invention will make the gist of the present invention unclear, the detailed description will be omitted. In addition, in the description to be described later, a typical embodiment for achieving the above-mentioned technical problems will be given. For the other embodiments mentioned in the present invention, they are included in the constitution of the present invention and will not be described again.

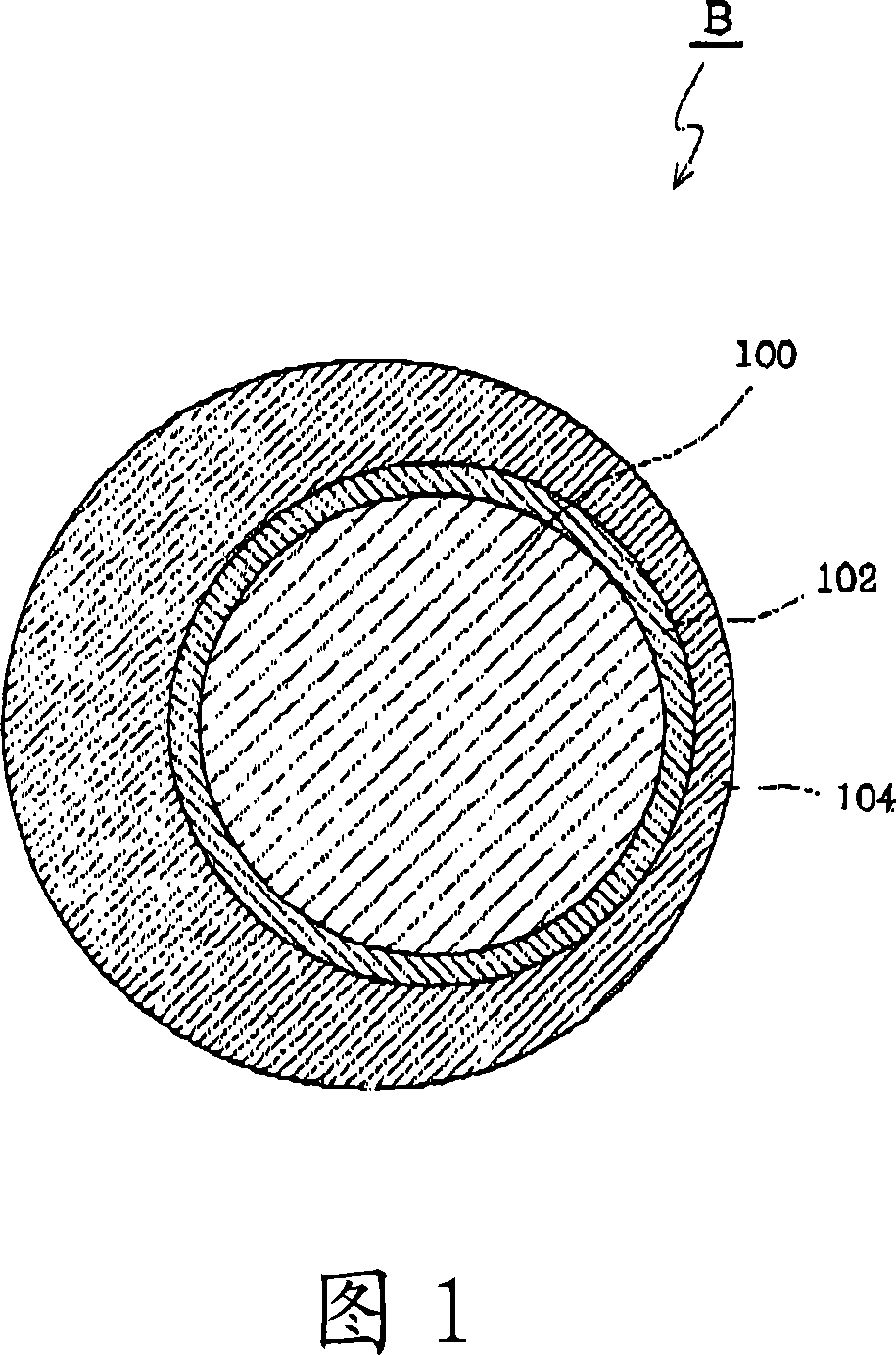

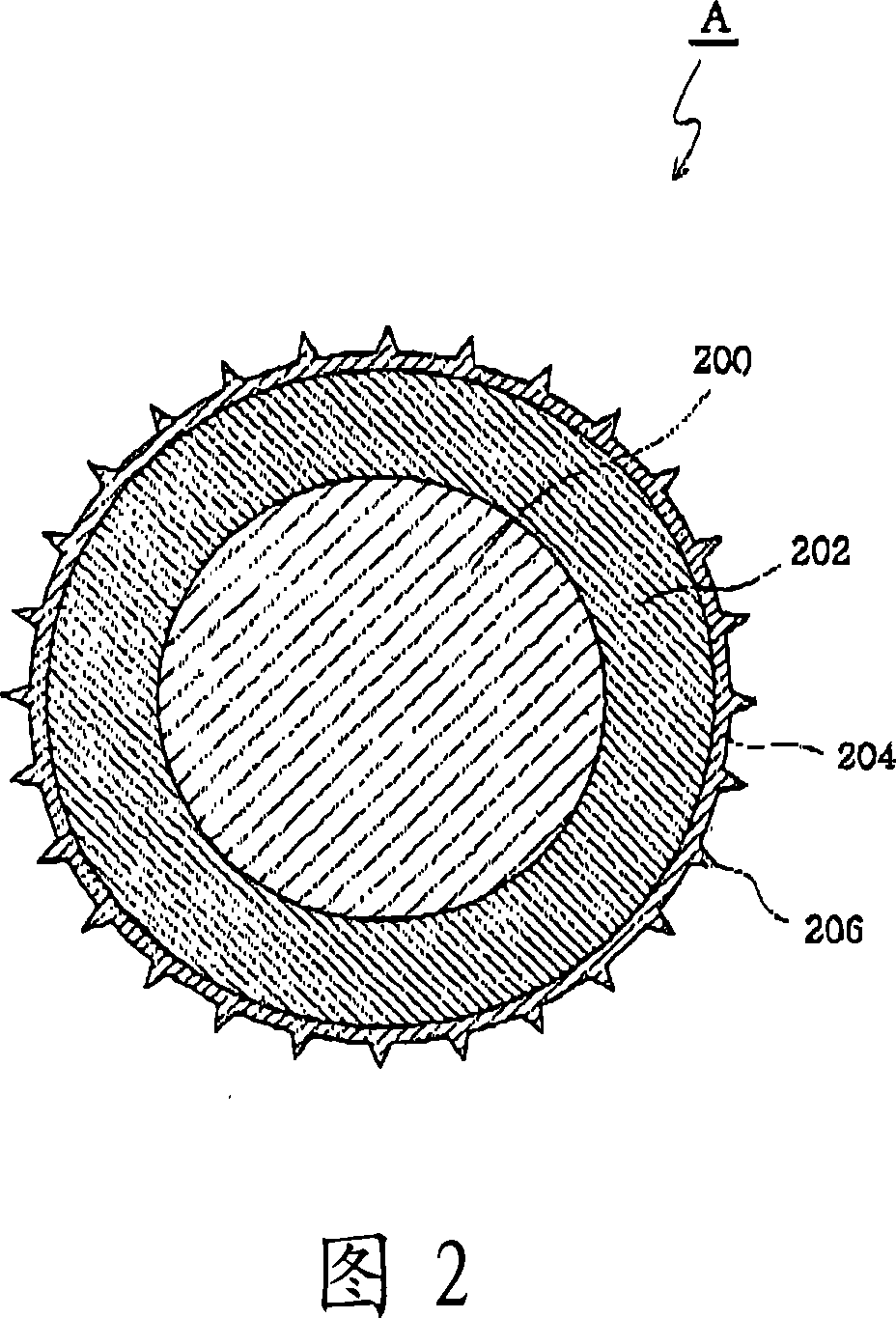

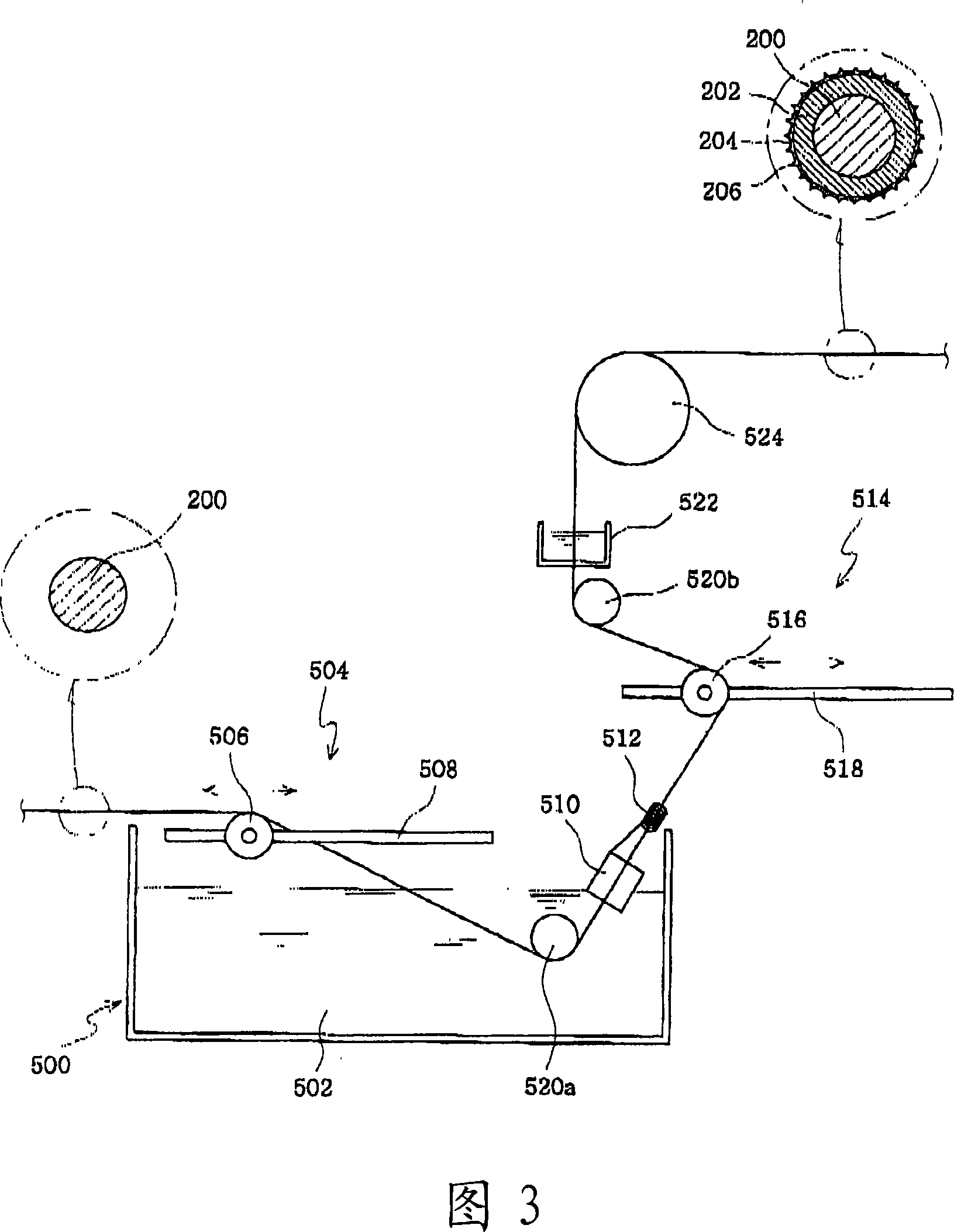

[0034] The present invention realizes an apparatus and method for producing a matt galvanized steel wire that is easy to be colored and painted by minimizing the thickness of the pure zinc layer and maximizing the alloy layer while forming a uniform plating layer and forming fine protrusions .

[0035] For this reason, the structure of a ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap