High constriction acrylic fibre tow preparing method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

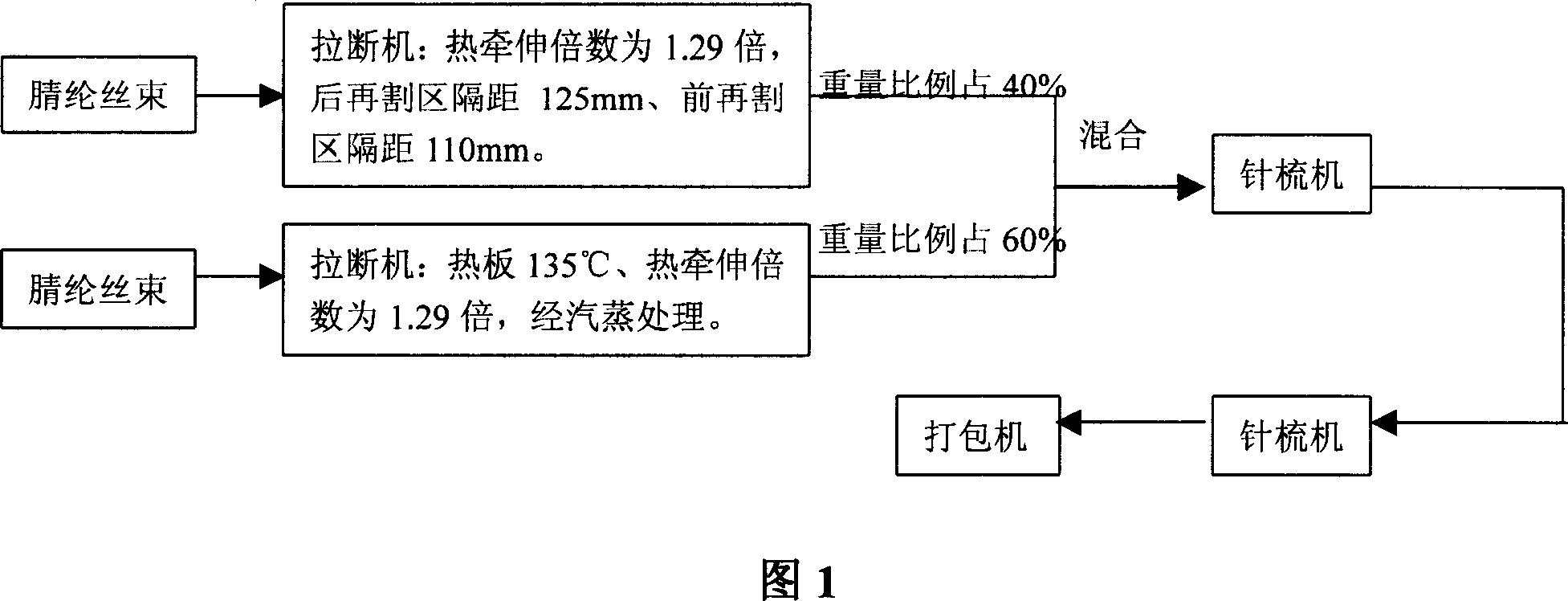

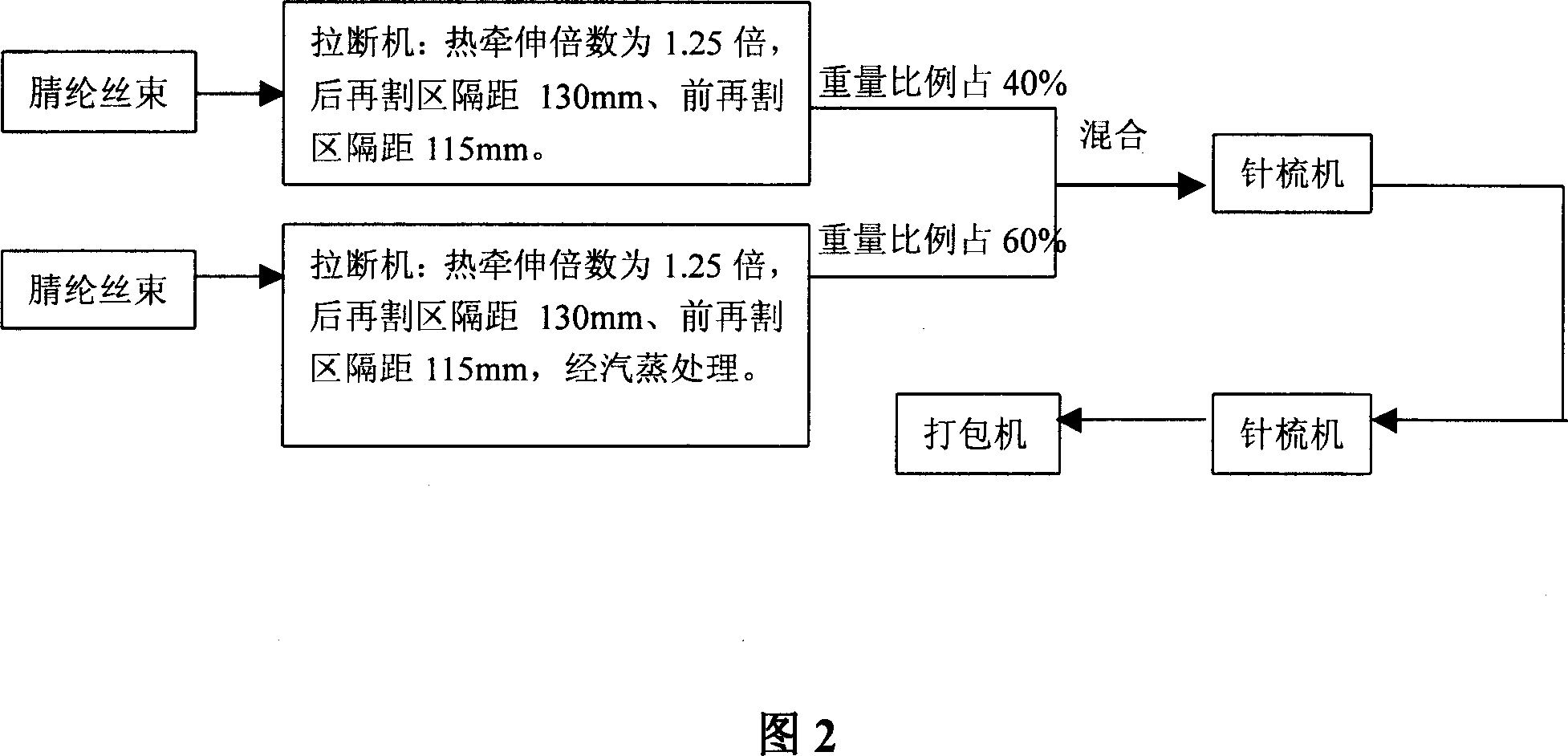

[0016] The new method of high-shrinkage acrylic fiber tow sliver production was carried out in the second workshop of the acrylic fiber factory of Daqing Petrochemical Company, and the expected effect was received. The production cost decreased, the consumption of electric heating plates and instrument accessories was reduced, and the spare parts of the breaking machine equipment remained at the original level. In the entire production process, only the production process of the stretching machine has been improved, and other production processes remain the original process. The production process details of the breaking process are as follows:

[0017] Pull off area

[0018] Pull off area

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com