Paper globe and its manufacture method

A manufacturing method and technology of a globe, applied in the field of educational demonstration equipment, can solve problems such as difficult price reduction, blocked exports, labor-intensive hours, etc., and achieve the effects of shortening the production cycle, improving production efficiency, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

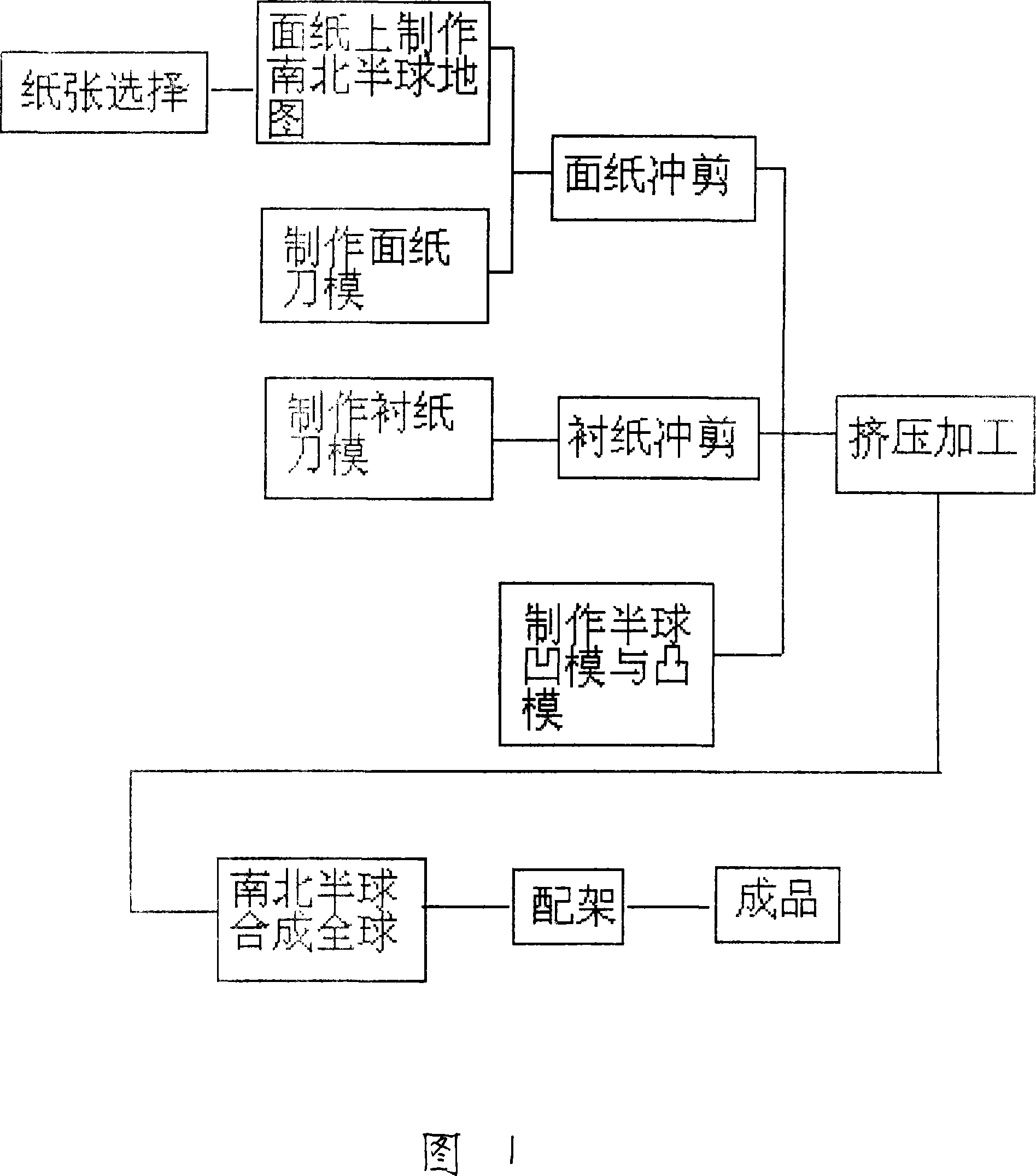

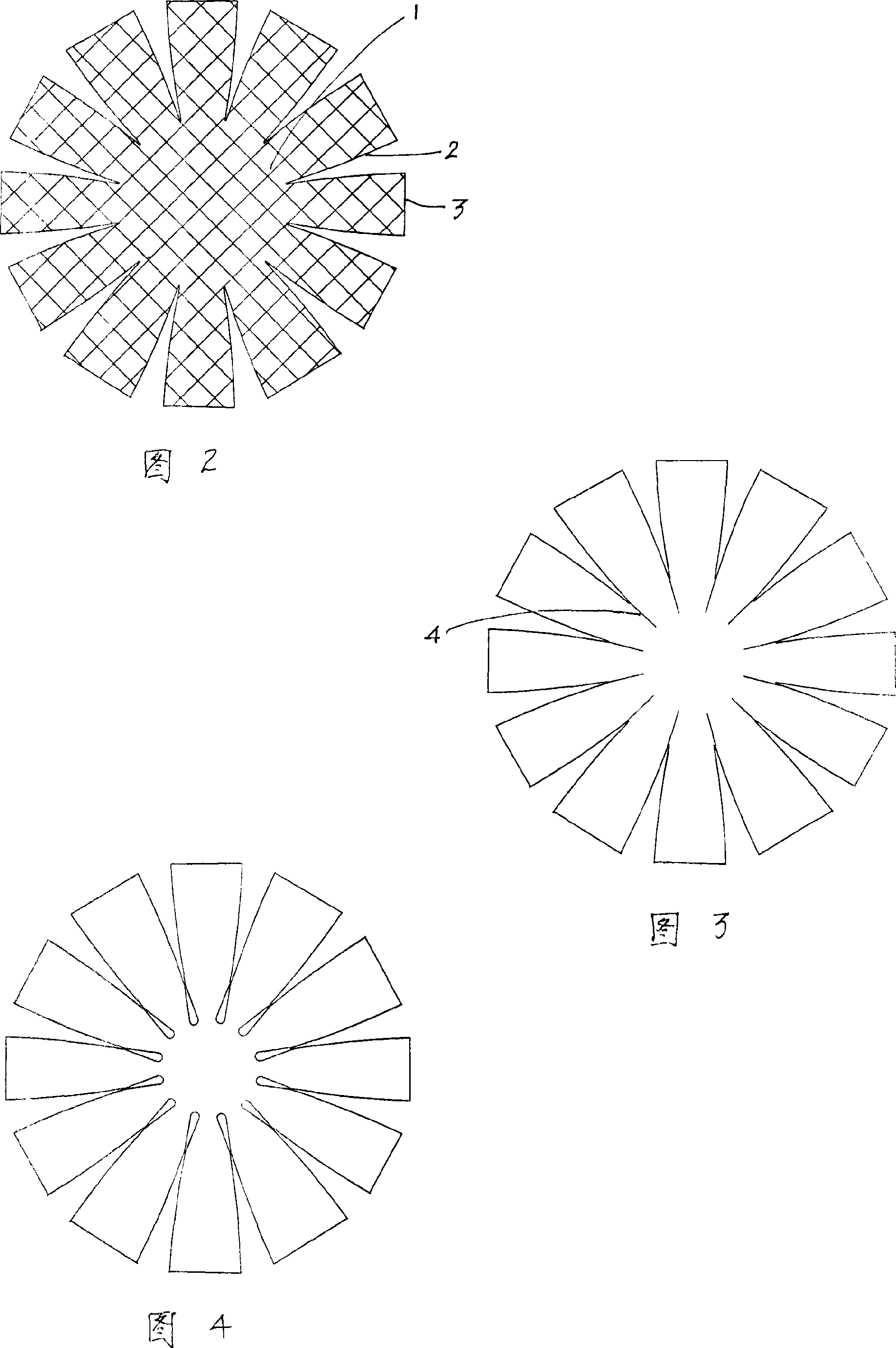

[0012] Shown in accompanying drawing 1, a kind of papery globe of the present invention, the sphere is all made of paper; It is characterized in that: the method for making this papery globe at least comprises the following steps: a. select as face paper and backing paper Paper; b. Printing patterns of the northern and southern hemispheres on the face paper; c. Making a die for punching and cutting the face paper; d. Punching and cutting the face paper; e. Making a die for punching and cutting the lining paper at the same time as c; f. Cut the backing paper; g. Make the hemispherical die and punch at the same time as c and e; h. Extrude the face paper and the backing paper together to form a hemisphere; i. Synthesize the northern and southern hemispheres into a global globe; j. Match the frame; k. finished product;

[0013] The paper selected in said step a needs to be made of better material, and has a thickness greater than 0.1mm, and needs to be thickened as the diameter of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com