Electric binding terminal

A technology of connecting terminals and connecting terminals, applied in the direction of electrical components, connecting end caps, conductive connections, etc., can solve problems such as limiting the minimum cross-section of current conduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

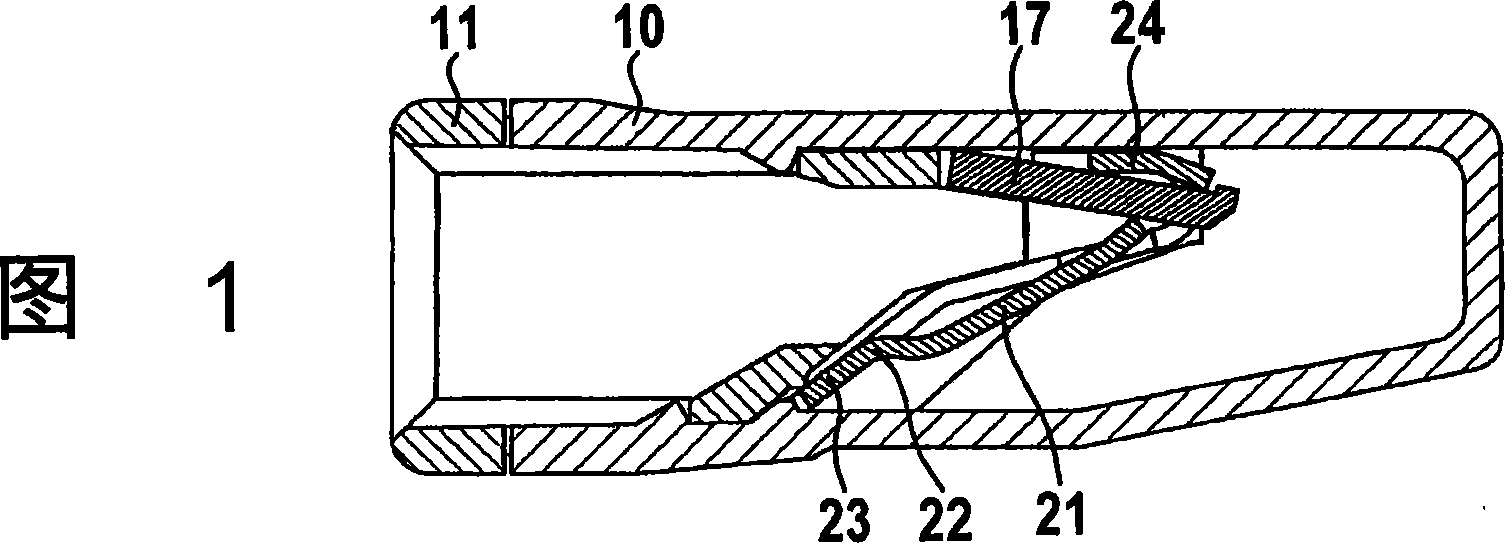

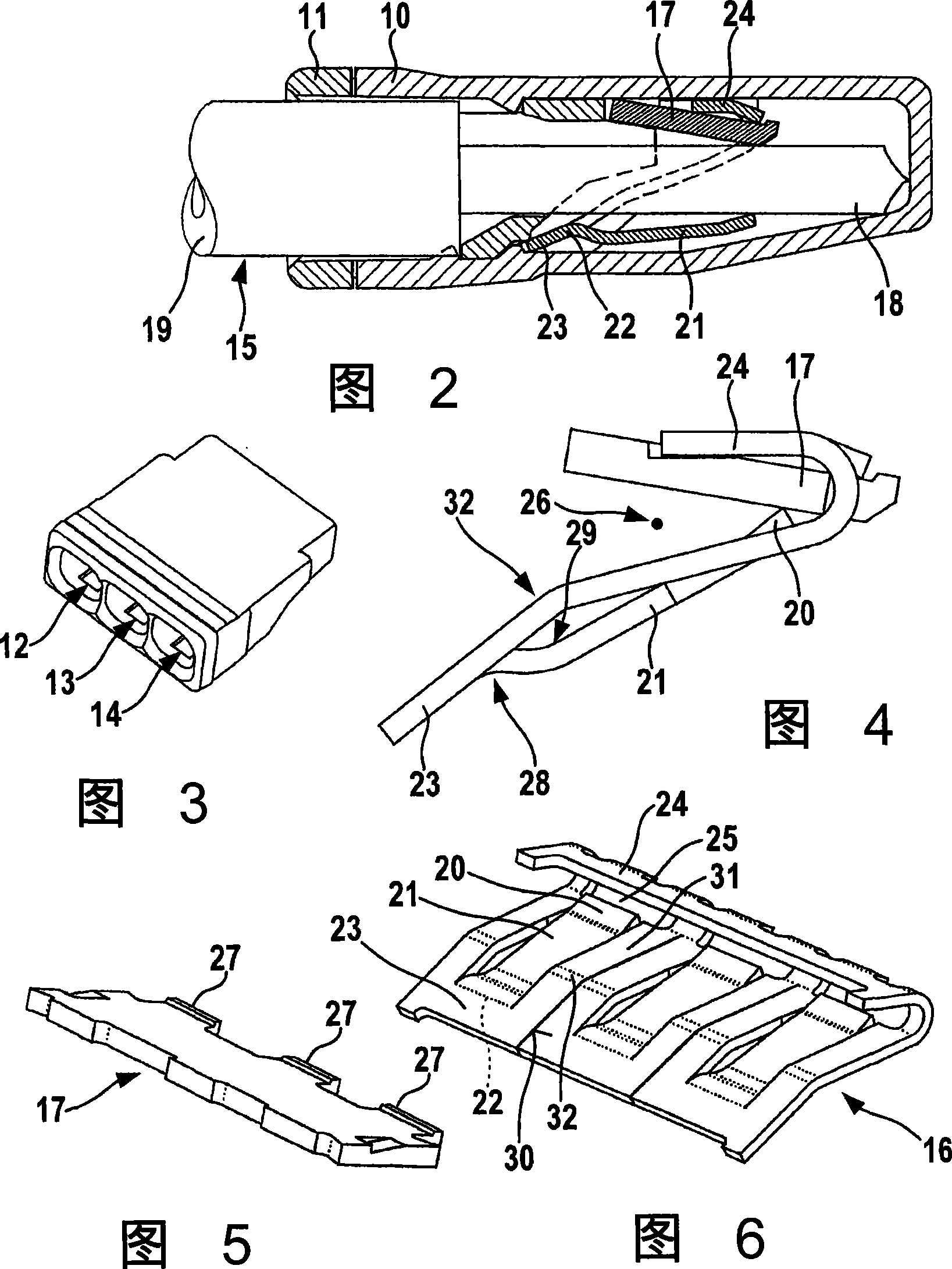

[0023] Fig. 1 shows the cross-sectional view of terminal box 10, and terminal box 10 has a box cover 11 that is arranged along the wire insertion direction, and this box cover 11 has wire insertion openings 12, 13 and 14, so that the total number of inserting in the same orientation and parallel is Three wires 15 (see Figure 3).

[0024] Figures 4, 5 and 6 show the contacts incorporated into the terminal box. The contact is composed of a spring steel plate 16 (see FIG. 6 ) and a bus bar 17 (see FIG. 5 ), and the bus bar 17 is made of copper with good electrical conductivity.

[0025] Corresponding to the number of clamping points, three leaf spring tongues 21 are punched out of the spring steel plate 16 , whereby window recesses are produced in the spring steel plate. The size of the window recess corresponds substantially to the size of the punched-out leaf spring plus the end section 25 , best seen in FIG. 6 . The wires 15 are inserted through the window openings, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com