An electric pencil sharpener

A pencil machine and pencil technology, which is applied to sharpening devices, printing, office supplies, etc., can solve the problems of complex device, increase cost, increase overall size, etc., and achieve the effect of simple device as a whole, low cost, and simplified internal structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

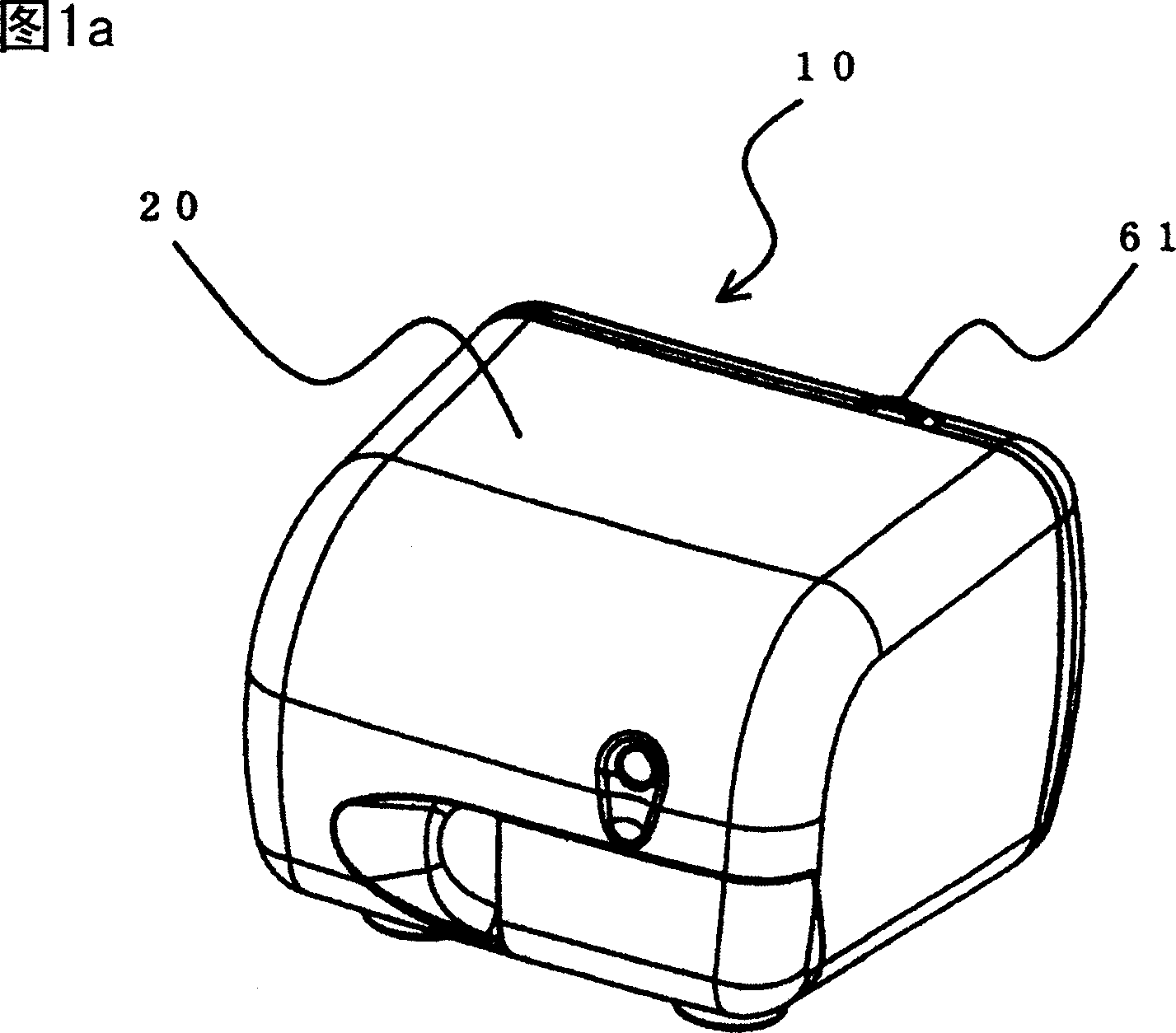

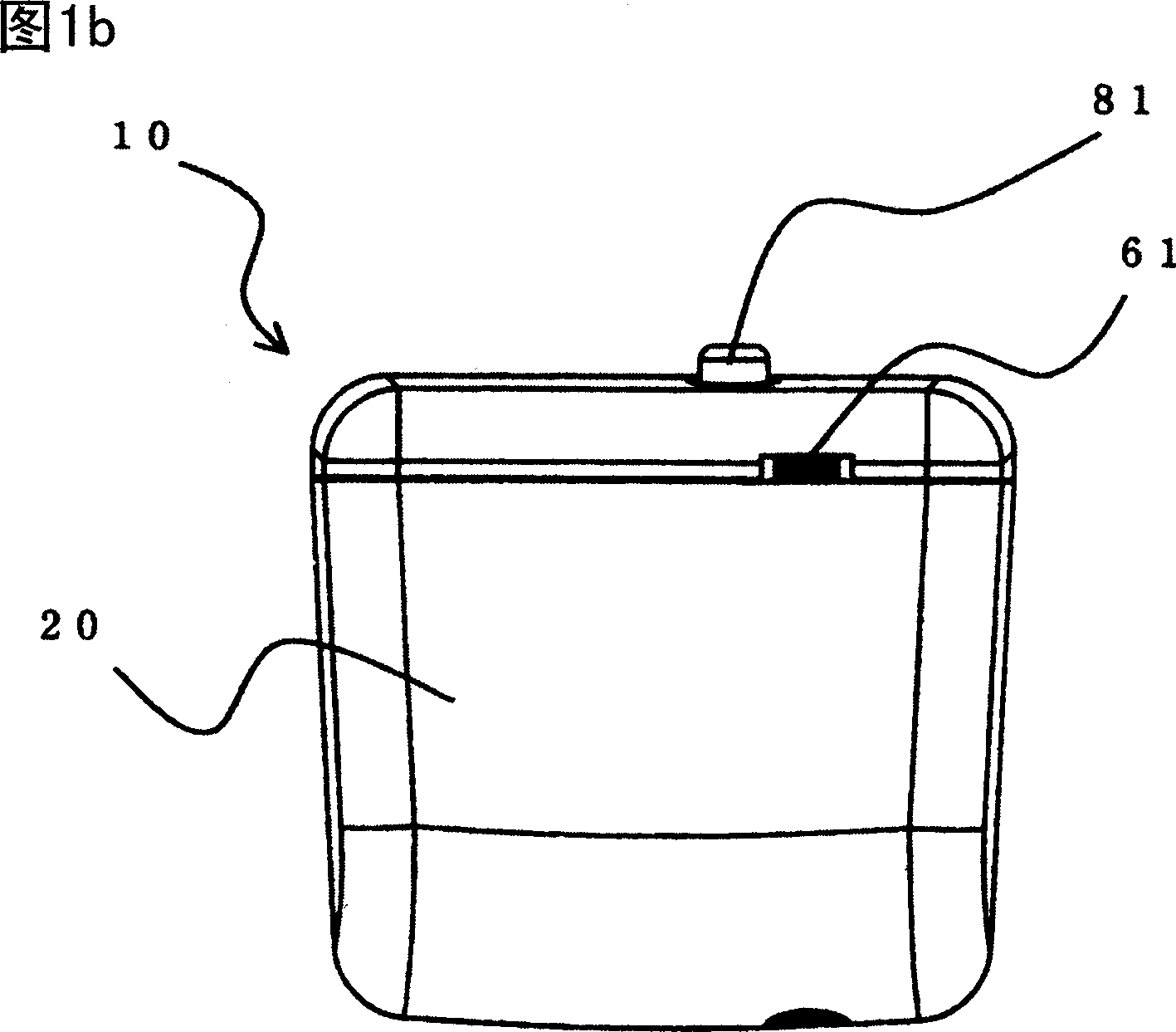

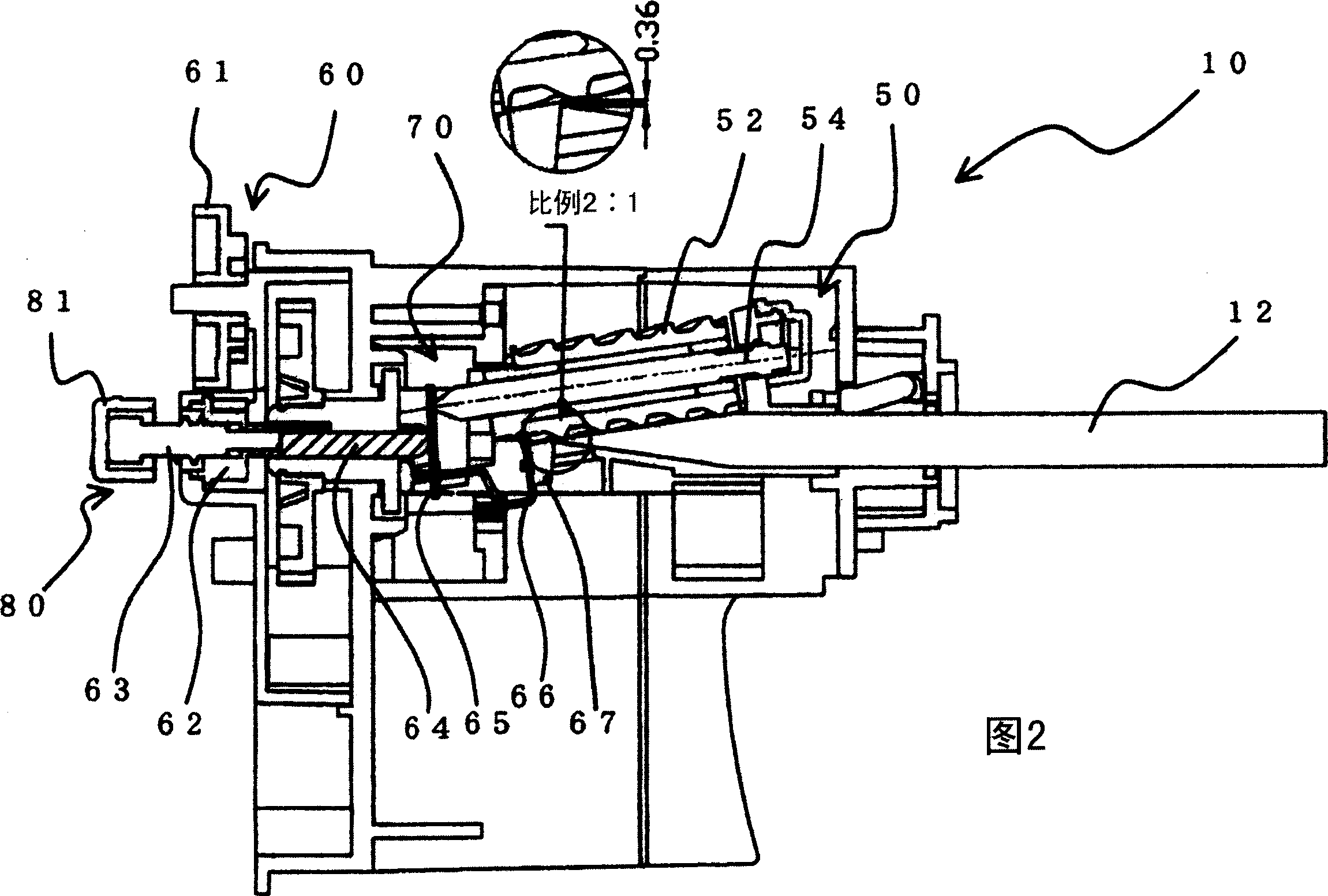

[0048] The main body cover 20 is a rectangular parallelepiped box as a whole, and a part of its outer surface is protrudingly provided with a core tip adjustment knob 61 and a button 81 of the broken core removal mechanism, and is at a position opposite to the button setting part of the broken core removal mechanism. Comes with a pencil slot.

[0049] Inside the main body cover, the above-mentioned drive mechanism, transmission mechanism, cutting mechanism, core tip adjustment mechanism, redundant cutting prevention mechanism and broken core removal mechanism are accommodated.

[0050] The drive mechanism 30 is composed of a drive unit 32 and a power supply 34 . The drive unit 32 uses a motor in this embodiment. A gear is installed on the motor, and the power is transmitted to the transmission mechanism 40 through the gear. Although an AC power source is used for the power supply 34 in this embodiment, a DC power source may also be used.

[0051] Also, the switch of the dri...

Embodiment 2

[0066] As another embodiment of the present invention, it is disclosed that the structure constituting the core tip adjustment mechanism 60 and the broken core removal mechanism 80 is realized simultaneously by one operation part. The operating principle is the same as that of Embodiment 1, but the structure is different as follows. In the second embodiment shown in FIG. 5 , the rotary knob 61 and the button 81 which are different components in the first embodiment are integrally formed as a core tip adjustment knob 90 . Although the direction of the embodiment of FIG. 5 is opposite to that of the embodiment of FIG. 2 , by rotating and adjusting the core tip adjustment knob 90, the core tip adjustment knob 90 provided with thread teeth is rotating and its front end 92 presses the coupling part 100, and the combination The member 100 further presses the shaft 110 such that the front end of the shaft presses the vicinity of the central portion of the plate 120 . Thereby, the lo...

Embodiment 3

[0069] Furthermore, in another embodiment, by making the switch box for performing detection when the pencil is inserted into the electric pencil sharpener as shown in the figure, it can be provided with various functions.

[0070] The switch box 150 is composed of a pencil insertion part switch lever 160 , a switch piece 170 , a switch 180 , a chip tray detection part 190 , and a switch lever 200 .

[0071] The switch lever 160 is a protrusion protruding from the pencil insertion hole, and once the pencil enters, it is pushed out in the horizontal direction, and the insertion part switch 162 is operated thereby. A portion 164 and a switch lever protrusion 166 are formed.

[0072] The switch piece 170 has a structure in which the switch lever convex portion 166 presses the switch piece convex portion 172 and presses the terminal 182 of the switch 180 .

[0073] The switch 180 is a part connected to a power source, and performs an operation of switching current. A terminal 18...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com