Vibration damper

一种防振装置、抑制振动的技术,应用在动力装置、摩擦减振器、运输和包装等方向,能够解决易劣化、耐久性降低、影响等问题,达到防止滑动摩擦变动、防止滑动部劣化、防止摩擦力过大的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

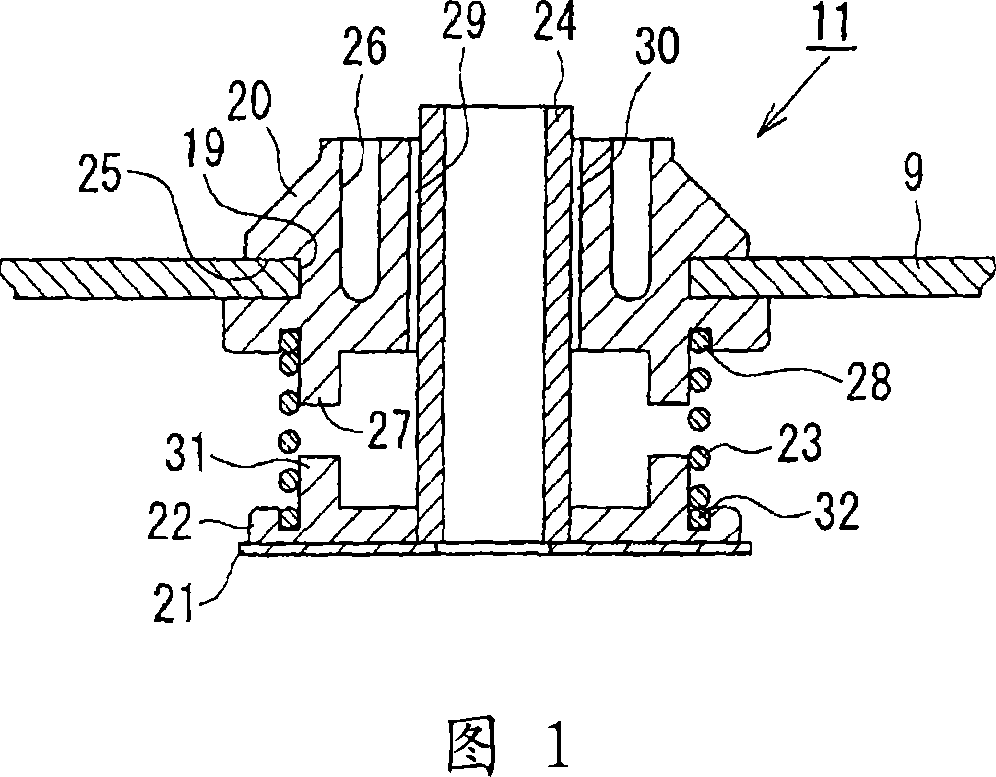

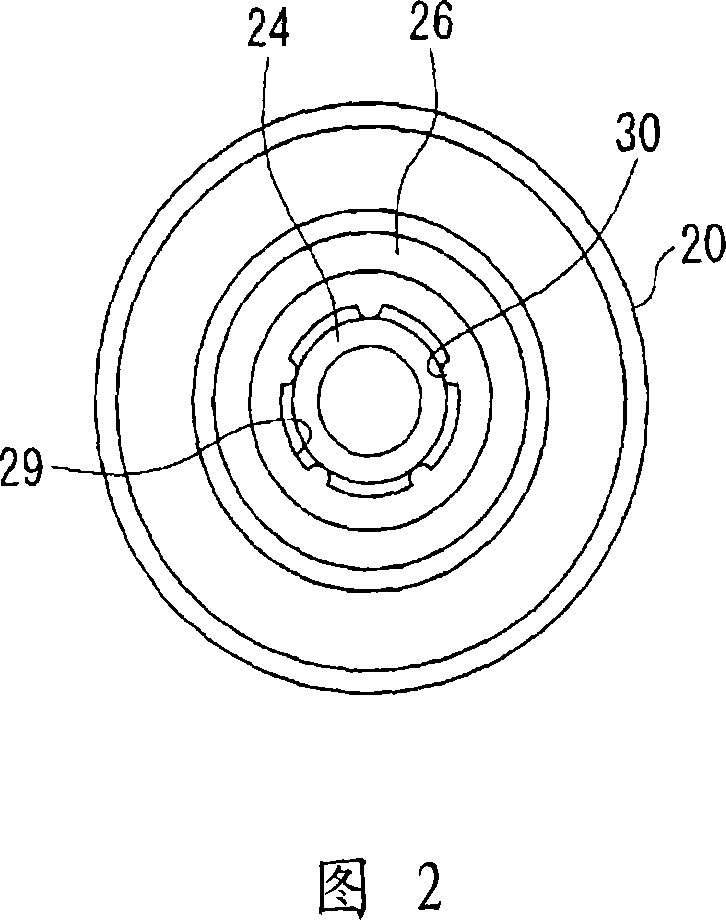

[0049] Embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

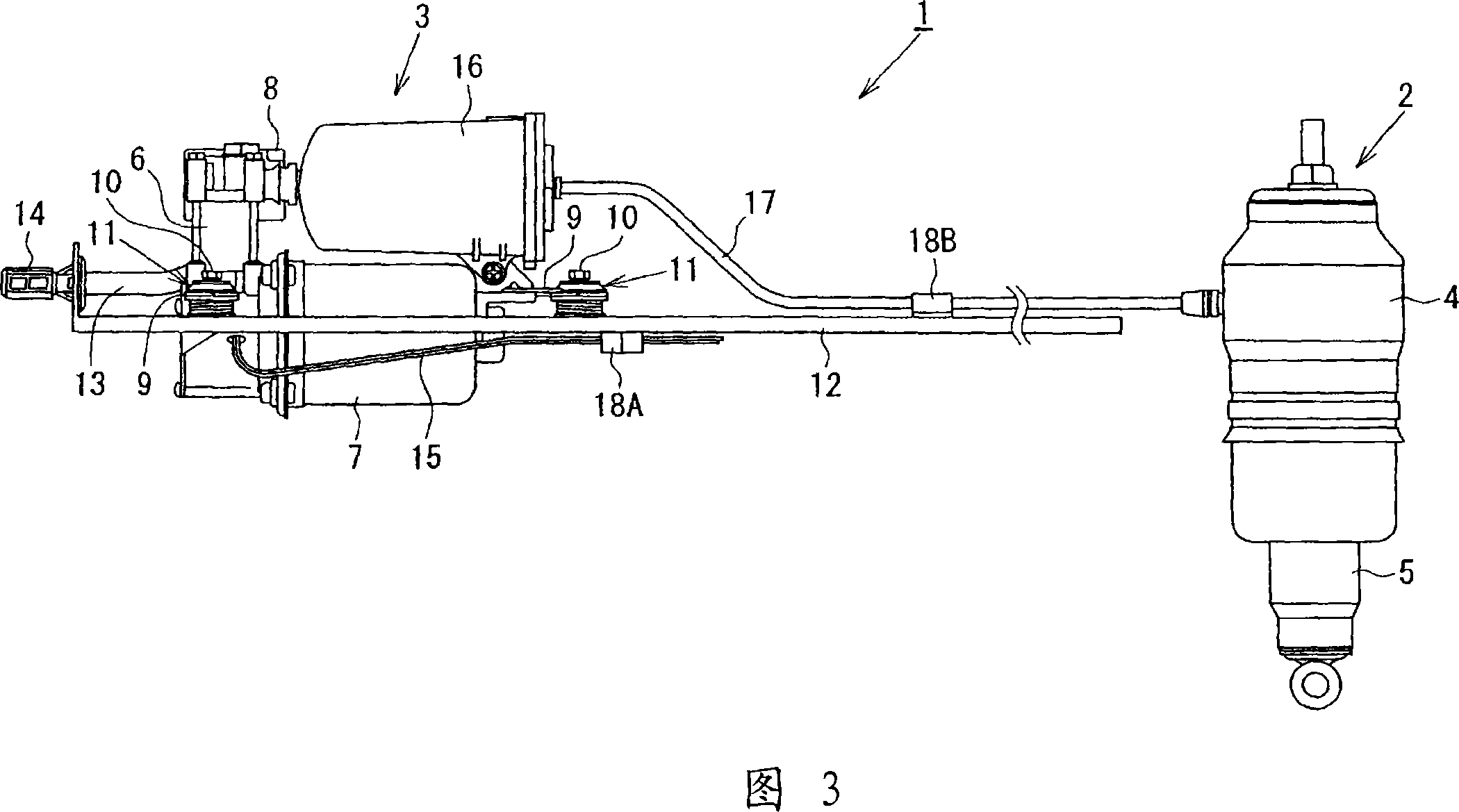

[0050] A first embodiment of the present invention will be described with reference to FIGS. 1 to 3 .

[0051] An automotive air suspension device to which the anti-vibration device of this embodiment is applied will be described with reference to FIG. 3 . As shown in Figure 3, the air suspension device 1 includes: an air suspension 2 installed between the upper and lower parts of the spring, that is, between the suspension member supporting the wheel and the vehicle body, for supplying air to the air suspension 2 Compressor unit 3 (first component) for compressing air.

[0052]The air suspension 2 is a structure in which an air spring 4 and a shock absorber 5 are integrally formed. The air spring 4 is a suspension spring that supports the vehicle body by its spring force, and the height of the vehicle can be adjusted by supplying and discharging compr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com