Gas replacement type trace quantity micro sampling-fetching pump

A micro-injection pump and gas replacement technology, applied in the direction of liquid variable volume machinery, pumps, machines/engines, etc., can solve the problems of complex flushing pipelines and cross-contamination, avoid the possibility of cross-contamination, and reduce sample errors. the effect of reducing the chance of being infected

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

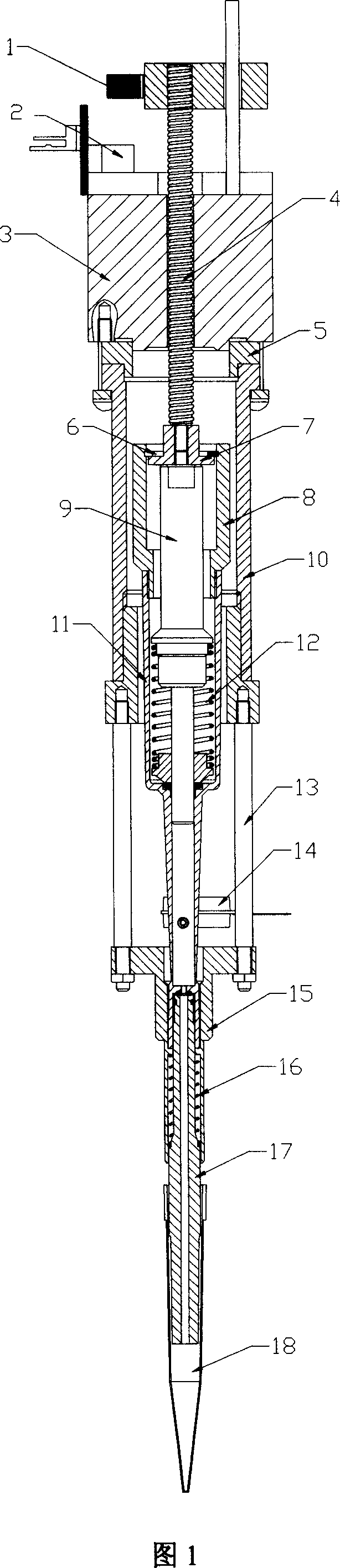

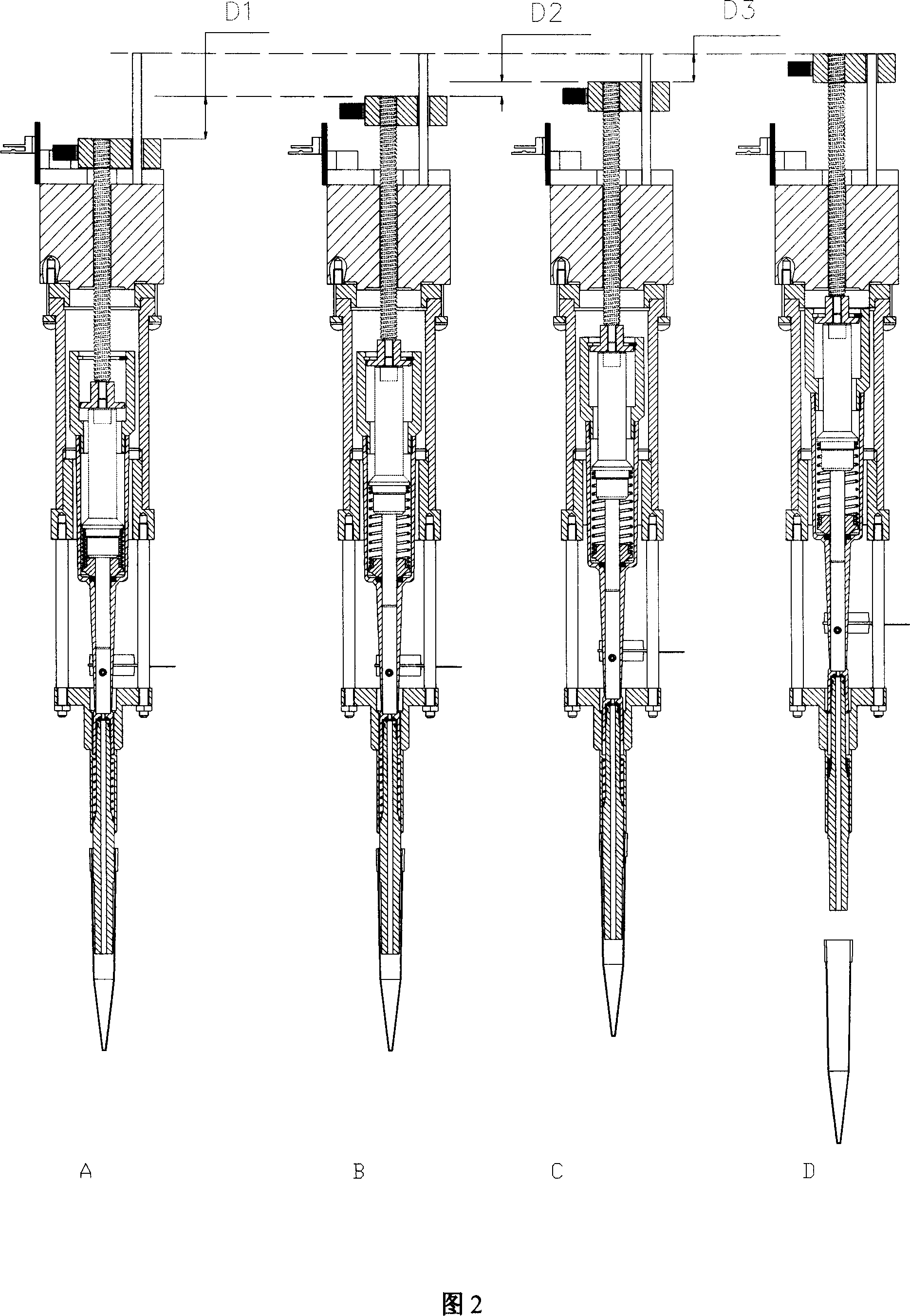

[0019] As shown in Figure 1, the gas displacement type micro-sampling pump with automatic tip removal device according to the present invention includes a pump body 10, a linear motor 3, a transmission screw 4, and a piston 9, which are connected sequentially from top to bottom as An integral sliding sleeve 8, a cylinder 11, a gun head 16, and a suction head removal sleeve 15, wherein the suction head removal sleeve 15 is fixed on the pump body 10 near the gun head.

[0020] Micro-pressure sensor 14 can also be set at the middle position of piston 9 bottoms and gun head 16, cooperates amplifier circuit again, can detect liquid level height sensitively and be enclosed within the suction head on the gun head whether cooperate closely etc. according to pressure change in cylinder.

[0021] The invention adopts a high-precision motor, and composes a zero-point reset device through a photoelectric sensor and a block connected to the transmission screw, which can control the movement...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com