Vibrating noise reducing B grade supporting fixed device of compressor

A technology for fixing devices and compressors, applied to compressors, refrigerators, refrigeration components, etc., can solve problems such as high low-frequency noise, increased balance of internal rotating parts, increased compressor weight, consistency, and increased cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to further illustrate the content, characteristics and effects of the present invention, give the following examples again and illustrate as follows in conjunction with the accompanying drawings:

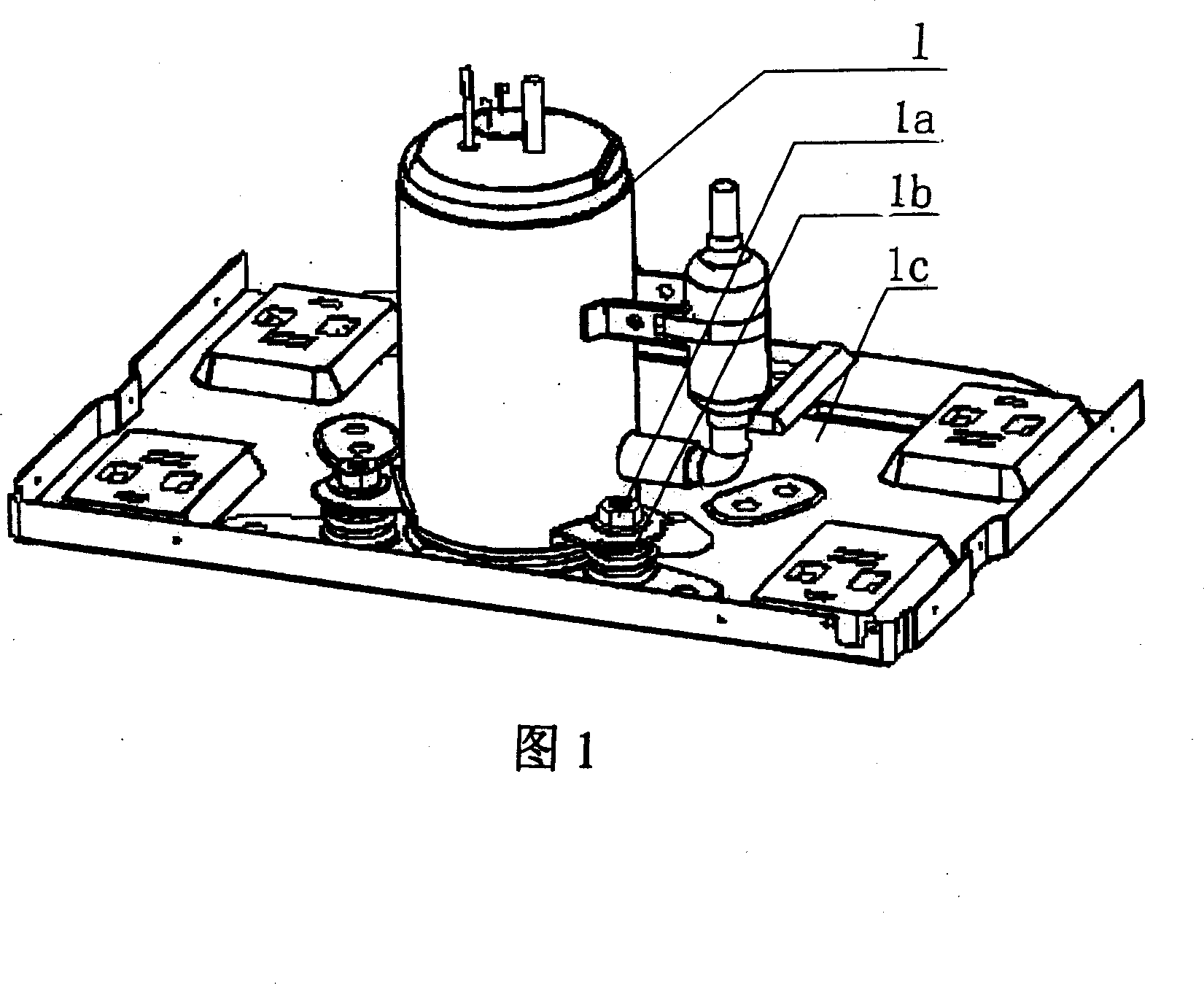

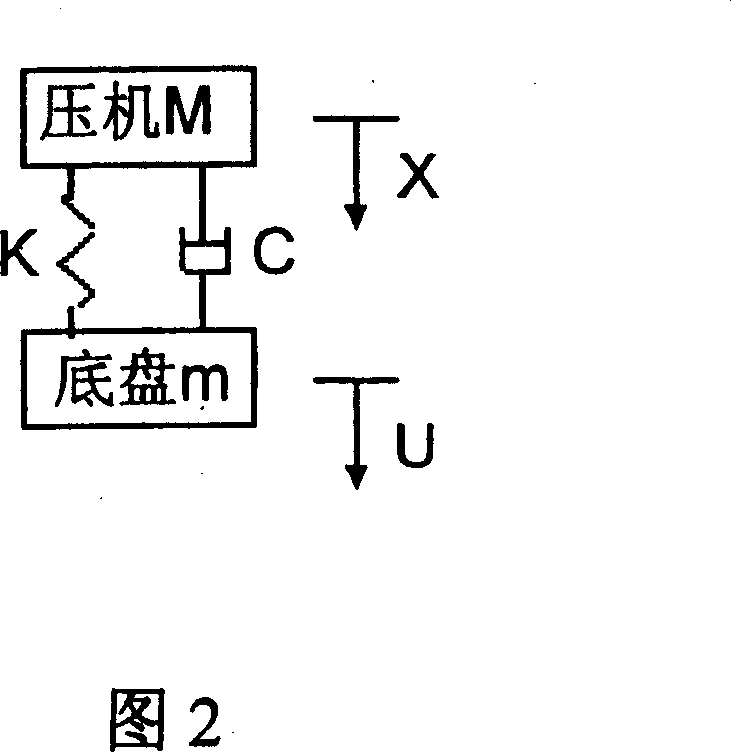

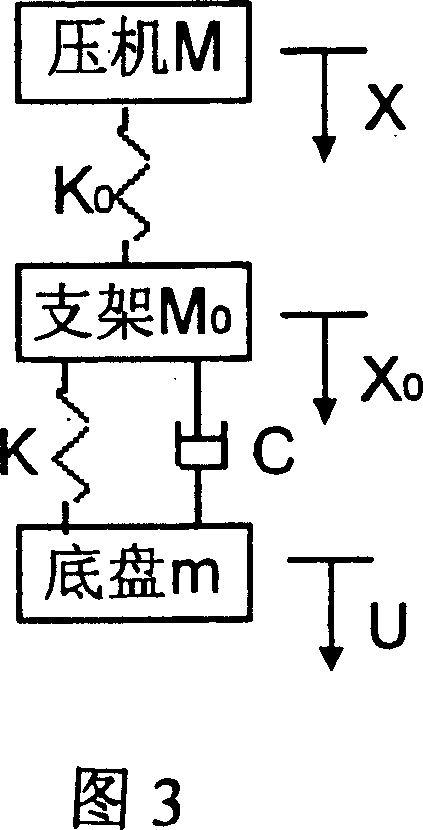

[0032] As shown in Figures 3-5, the technical solution structure of the secondary support and fixing device of the compressor for reducing vibration and noise of the present invention includes: a compressor 1 fixed to the air conditioner with three foot pieces having through holes 1a' separated by 120°; The compressor 1 is screwed to the bolt 1a of the air conditioner; it is composed of a rubber damping rubber pad connected to the bolt and padded under the foot of the compressor. In the middle and lower part of the machine casing, the bottom of the three feet with through holes 1a' is screwed to the upper and lower ends of which are welded with the same three feet and can accommodate the lower compressor casing through the damping rubber pad 1b. The three pins on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com