Process and device for regenerating the loaded washing agent in a physical gas wash

A technology of gas washing and detergent, applied in the direction of gas treatment, separation methods, chemical instruments and methods, etc., which can solve the problems of a large number of special equipment and operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

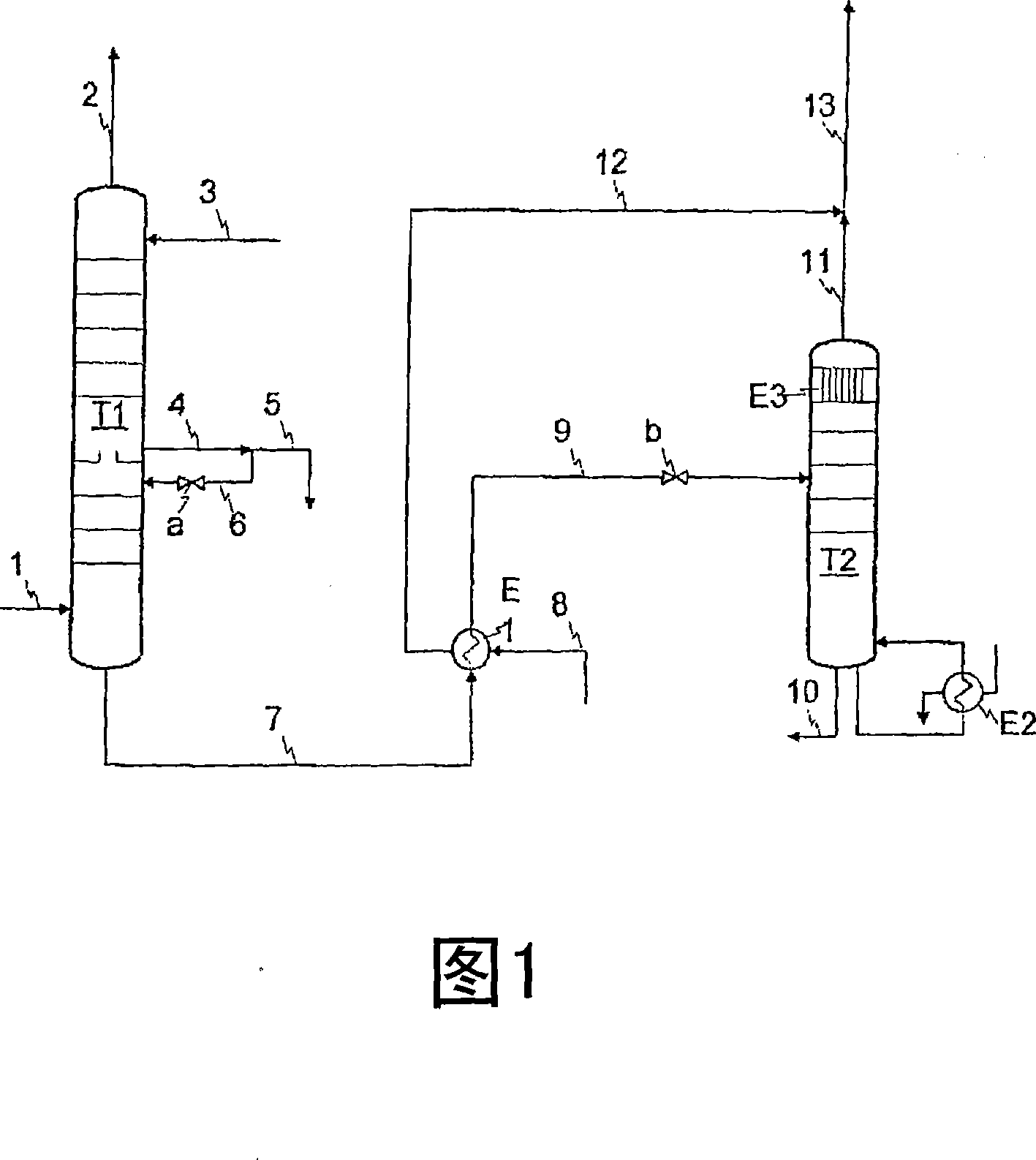

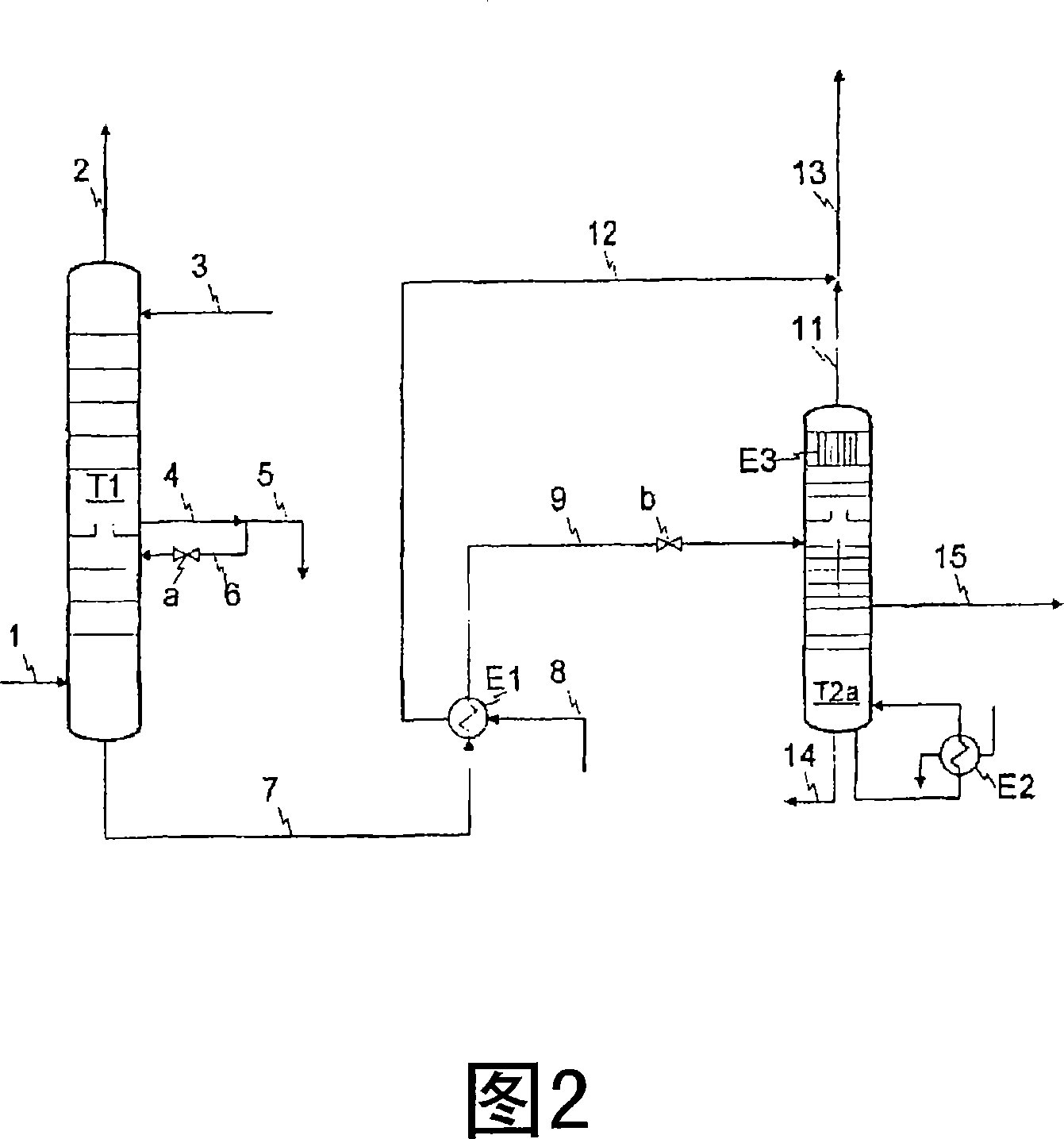

[0024] The invention will be explained in more detail below with reference to two exemplary embodiments shown in FIGS. 1 and 2 . Each of the exemplary embodiments relates to a methanol scrubbing in which raw synthesis gas containing water residues is purified from water and hydrogen cyanide (HCN) in a first scrubbing step and from carbon dioxide in a second scrubbing step (CO 2 ) and sulfur-containing gases (H 2 S, COS). A portion of the loaded (or loaded) methanol detergent extracted from the second wash step was used as the detergent in the first wash step. In the two figures, the same device parts are identified with the same symbols.

[0025]The gas stream to be purified is introduced via line 1 into the lower part of scrubber T1 in which it is largely purified of residual water and HCN. A purified gas stream, now mainly comprising hydrogen and carbon monoxide, is withdrawn from the scrubber and sent via line 2 . Liquid methanol is introduced as scrubbing agent via li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com