Dust remover

A dust collector and dust technology, applied in the direction of dust removal, separation of dispersed particles, chemical instruments and methods, etc., can solve the problems of installation, operation trouble, user acceptance difficulty, user inconvenience, etc., achieve low cost, wide application range, The effect of decontamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

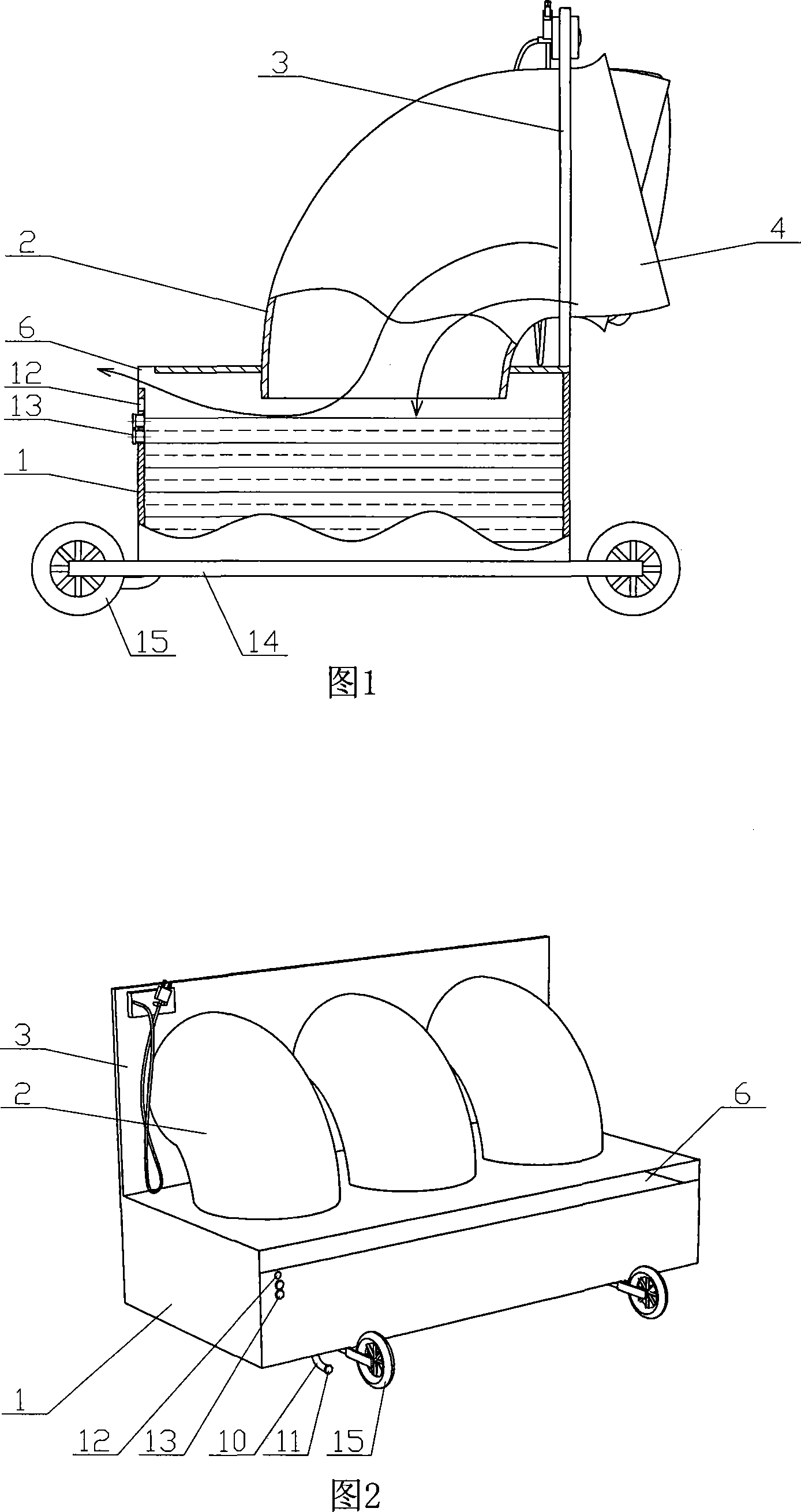

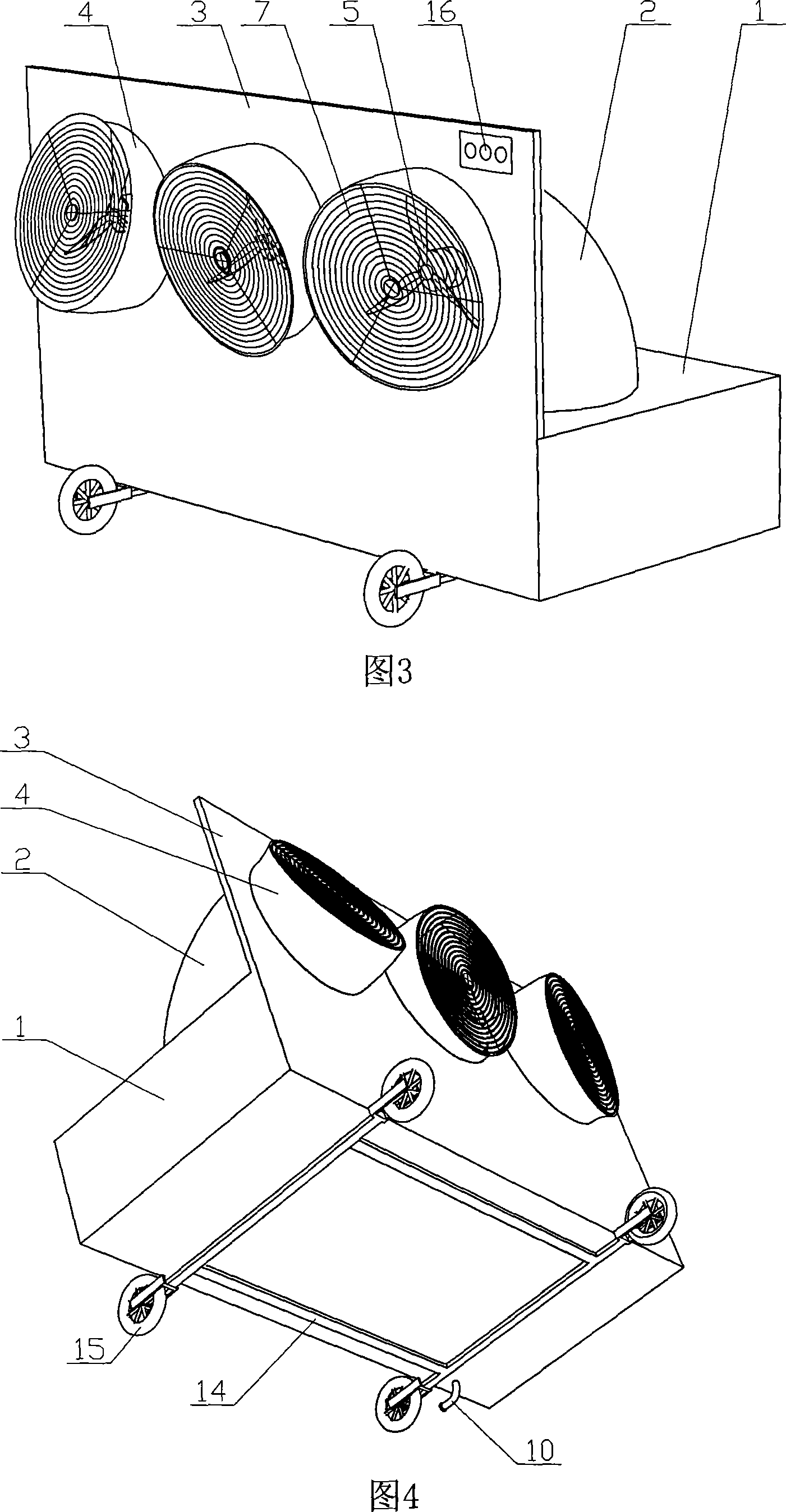

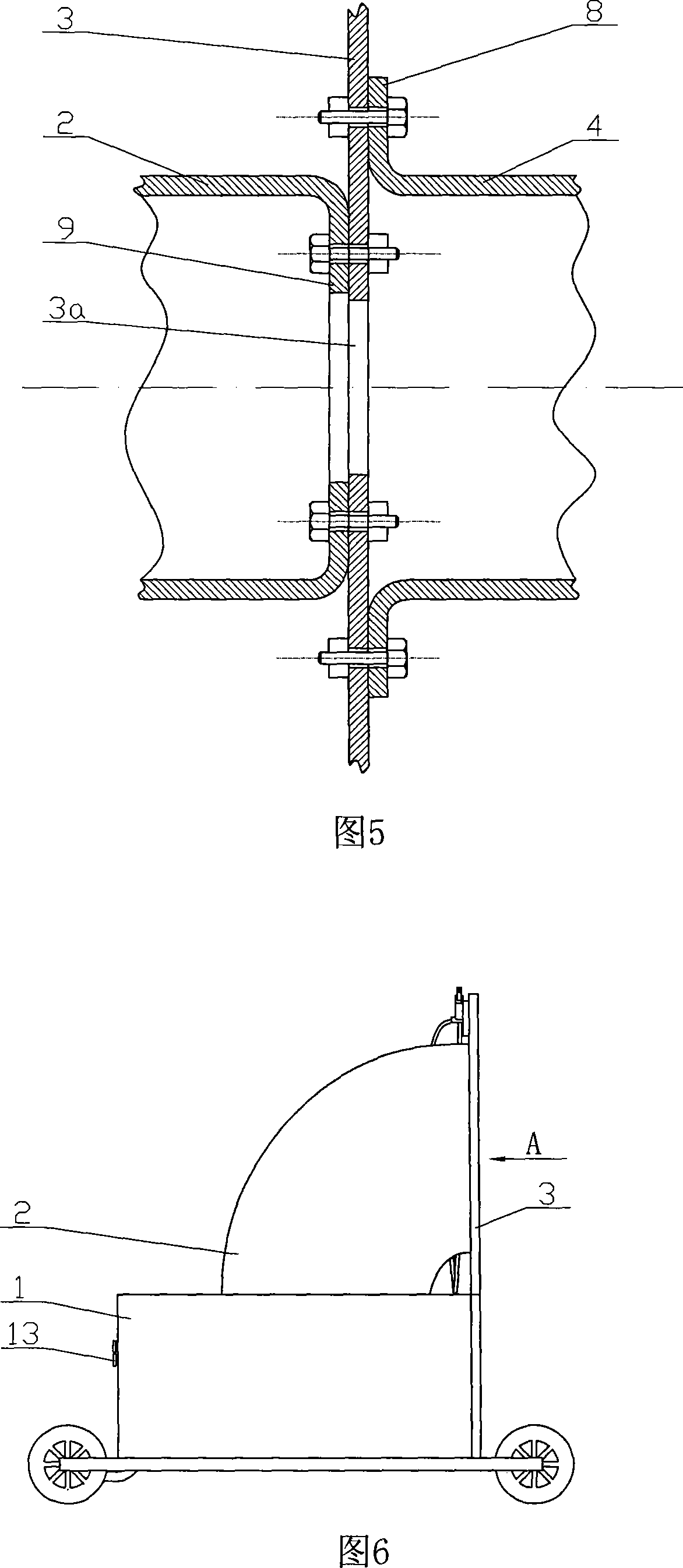

[0026] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

[0027] As shown in Fig. 1, Fig. 2, Fig. 3, Fig. 4 and Fig. 6, the water tank 1 containing the absorption liquid is rectangular, and the bottom frame 14 welded by four square tubes is fixed at the bottom of the water tank 1, and the bottom frame 14 It plays the role of strengthening the strength of the water tank 1 and supporting the whole equipment and the weight of the absorption liquid. Rollers 15 are installed on the four corners of the underframe 14 to improve the mobility of the equipment. The bottom of the water tank 1 is provided with a drain, which is led out from a drain pipe 10 , and a drain valve 11 is installed at the outlet of the drain pipe 10 . The upper part of the water tank 1 rear end has a strip-shaped exhaust port 6, and on the wall near the exhaust port 6 at the water tank 1 rear end, there are three overflow ports 12 that can control th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com