Gear-type chair angle stepless regulation structure

A stepless adjustment and gear-type technology, which is applied to vehicle seats, special positions of vehicles, transportation and packaging, etc., can solve the problems of large seat back gap and the inability to realize dual gears to eliminate gaps at the same time, and achieve small gaps , Eliminate the seat gap, good dustproof effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

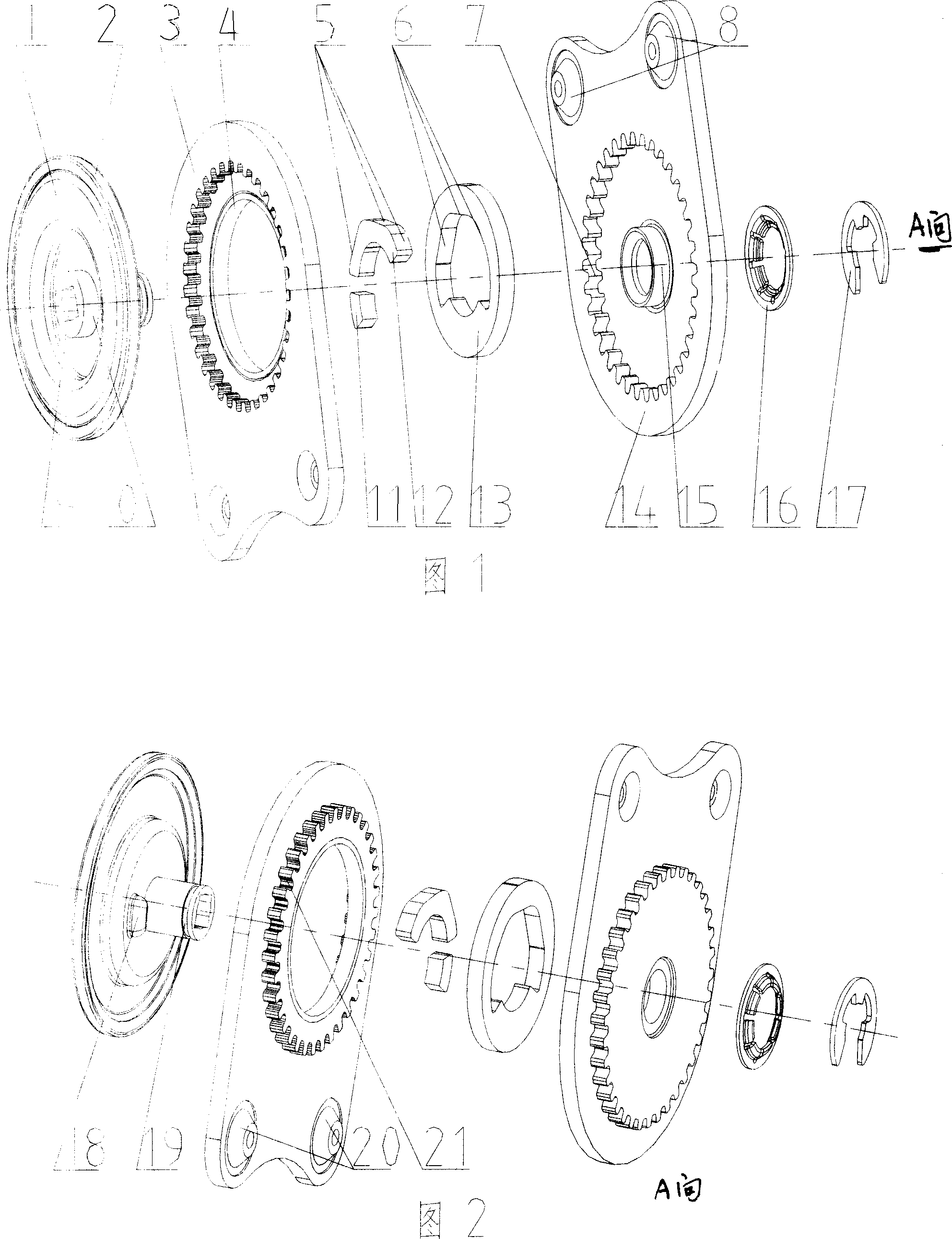

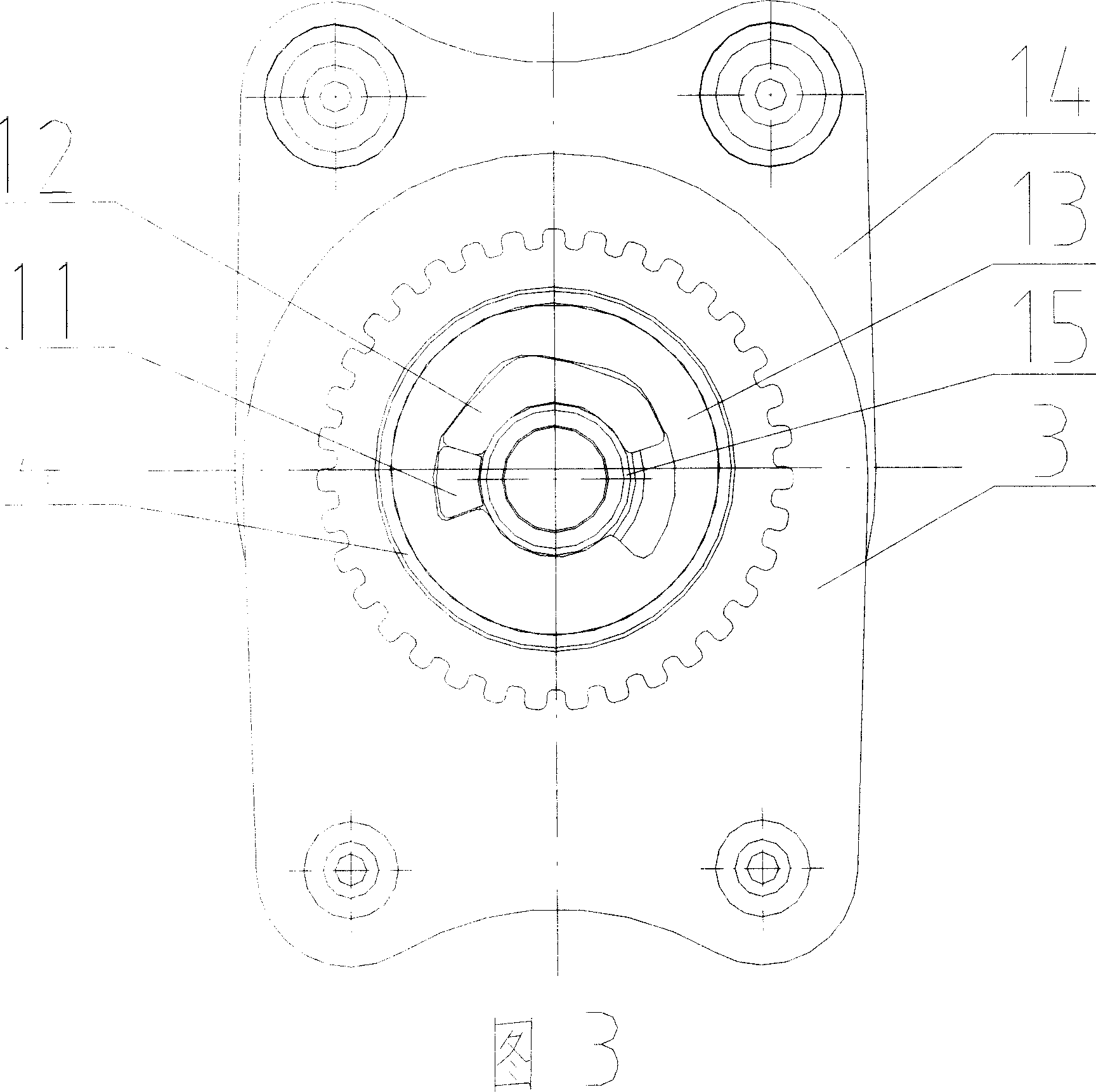

[0016] In Fig. 1 and Fig. 2, the present invention includes a gear transmission mechanism, a gap elimination mechanism, a spring and a driving mechanism. The gear transmission mechanism adopts a single-stage gear internal meshing planetary transmission with small tooth difference. The gear transmission mechanism includes an inner tooth plate 14 and an outer tooth plate 3. The outer tooth plate 14 is installed in the inner tooth plate 14 with a certain eccentricity, so that the inner teeth 7 Mesh with the external teeth 21 to realize the single-stage internal meshing transmission of the internal and external gears. When the operating torque acts on the drive mechanism, the internal tooth plate 14 and the external tooth plate 3 mesh with each other and produce planetary motion, so that the mutual The angle changes to achieve the purpose of adjusting the seat angle.

[0017] Due to the inevitable gap between the internal and external gears of mutual meshing and transmission, a co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com