Back-V-type automatic error-correction device

A technology of automatic deviation correction device and swing idler roller, which is applied in the direction of transportation and packaging, conveyor objects, conveyors, etc., can solve the problems of no automatic deviation correction function, weak deviation correction ability, inconvenient installation and adjustment, etc., and achieve remarkable deviation correction effect , wide application range and low maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] With reference to the accompanying drawings and preferred embodiments, the specific embodiments, structures, and features provided in accordance with the present invention are described in detail as follows:

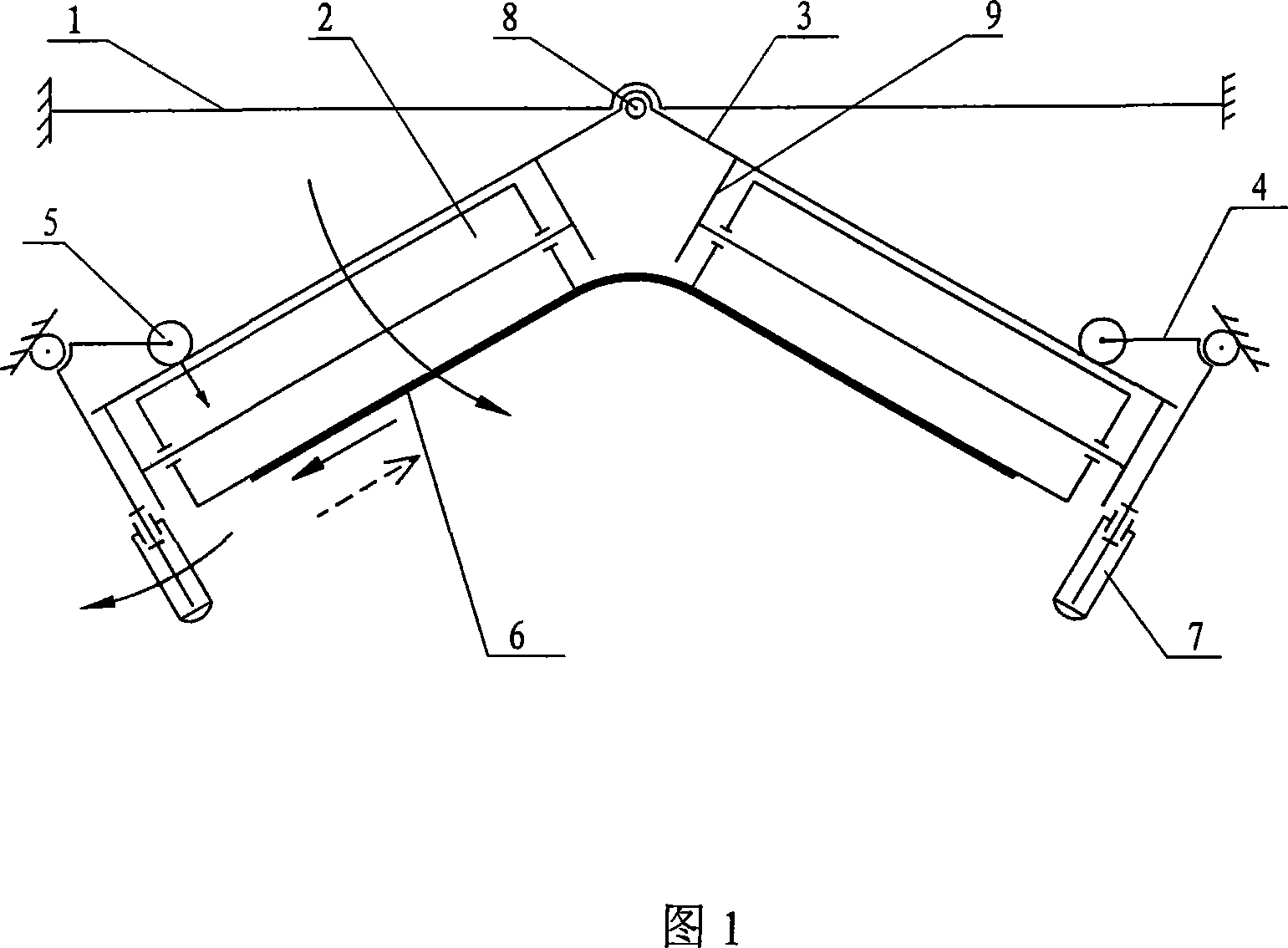

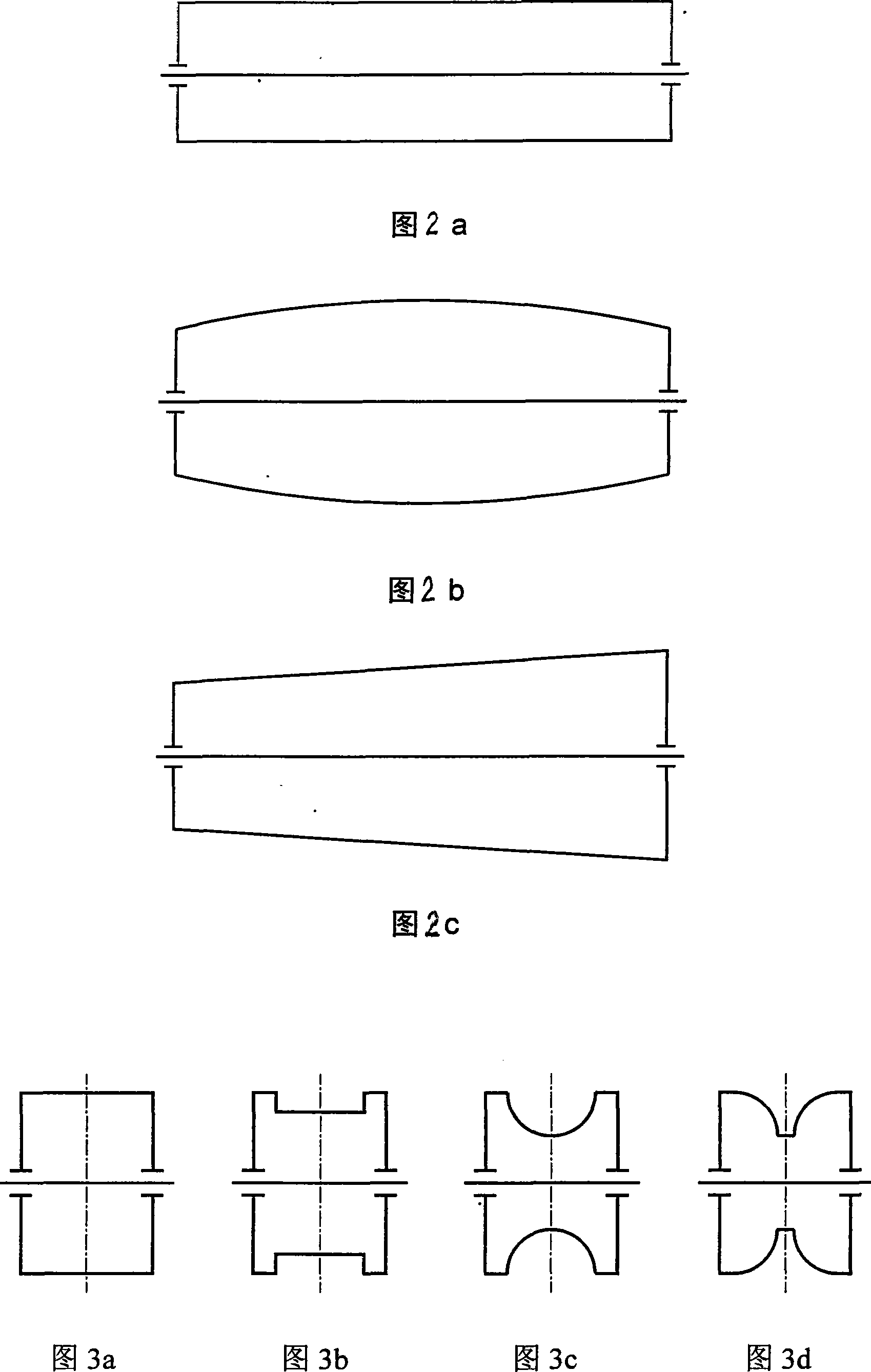

[0021] As shown in Figure 1, a reverse V-type automatic deviation correction device is characterized by a channel steel or other steel structure as a cross beam 1 for fixing on the belt conveyor frame, as a reverse V-shaped swinging roller frame 3 And the carrier of the roller 2. Corresponding to the cross beam 1 is provided with a reverse V-shaped swinging roller rack 3, the center of the swinging roller rack 3 is provided with a connecting shaft 8, the swinging roller rack 3 and the cross beam 1 are coaxially hinged at the center position, under the action of external force, the swinging support The roller frame 3 can swing freely in a certain angle range in the vertical plane; realize automatic centering. Two sets of side pillars 9 are symmetrically welded on the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com