Shock-wave sand stone extinguishing cannon

A technology of sand and gravel guns and fire-extinguishing guns is applied in the field of shock-wave sand-gravel fire-extinguishing guns, which can solve the problems of high labor intensity, high danger, and limited vehicle travel, and achieve high fire-extinguishing efficiency, energy saving, and long range Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

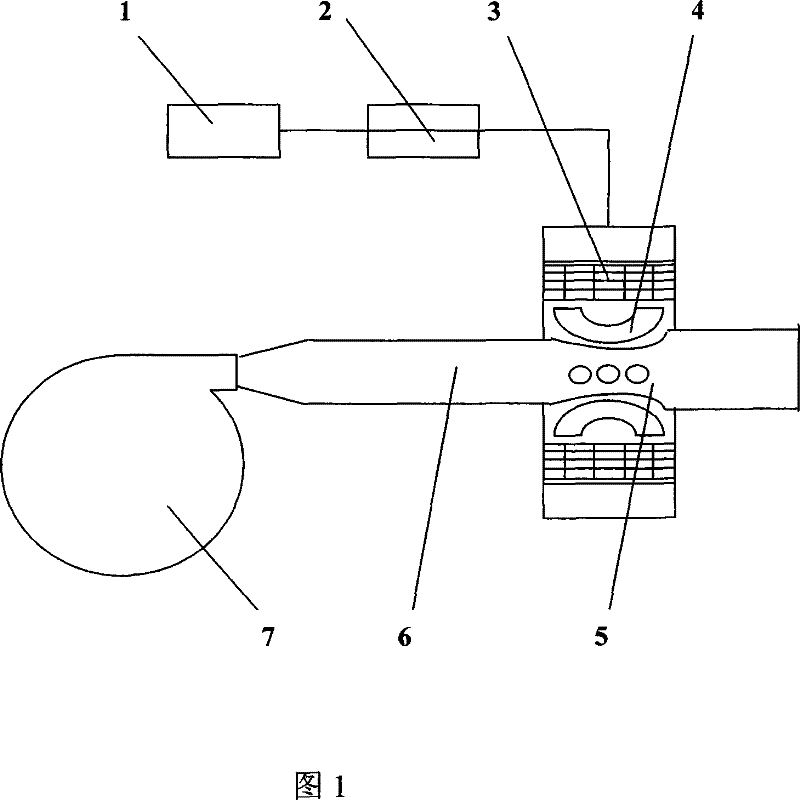

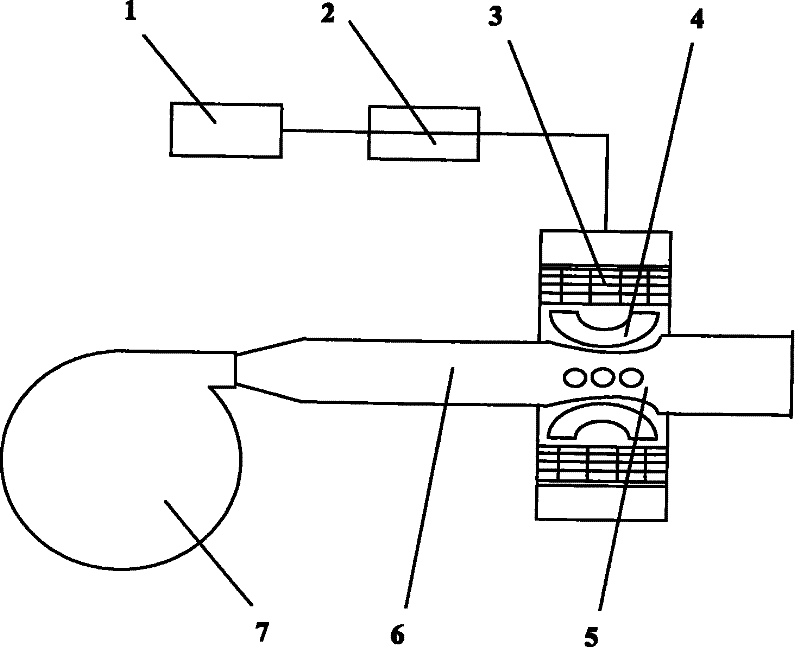

[0008] The main structure of the implementation of the present invention includes a compressed gas source 1, a compressed gas stop valve 2, a shock tube 3, a shock tube gravel cannon separation valve 4, a gravel cannon 5, sand and gravel 6, a gravel conveying mechanism 7 and gravel The mining machine 8 is assembled into a coordinated integrated long-range fire extinguishing gun through conventional technical process combination and assembly.

[0009] The shock tube 3 mentioned in the embodiment of the present invention is the power of the sandstone gun 5. It is a tubular structure with the same diameter, divided into a high-pressure cavity and a low-pressure cavity. Between the high-pressure cavity and the low-pressure cavity is a transient switch valve or The diaphragm is separated. The low-pressure chamber is filled with normal pressure medium, and the high-pressure chamber is filled with high-pressure air. The principle of the shock tube 3 is to use a higher gas pressure to i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com