Microporous ceramic filter with supersonic-wave cleaner

A technology of microporous ceramics and cleaning devices, which is applied in the field of filtration and can solve problems such as inability to pressurize materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

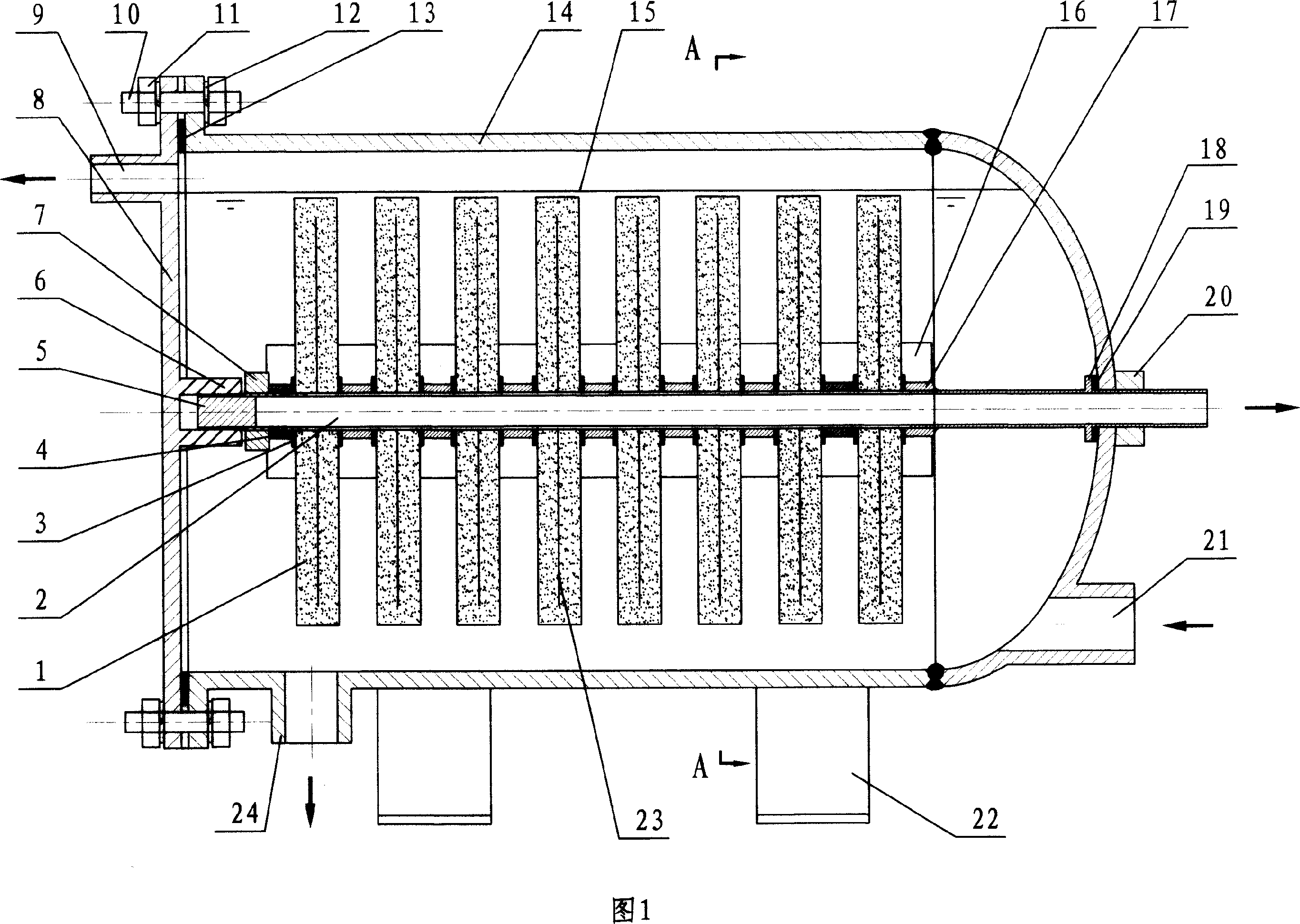

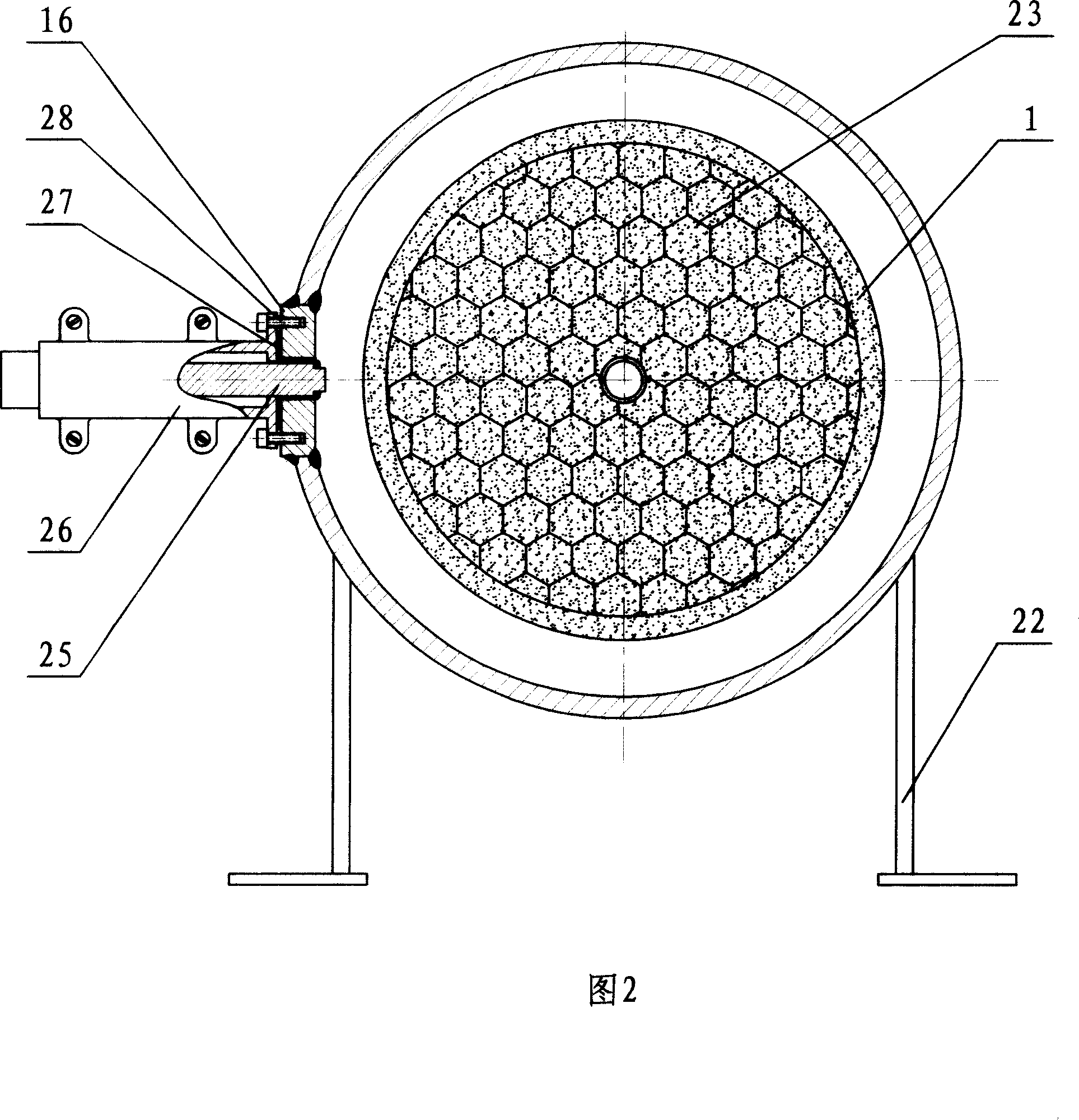

[0025] Embodiment 1: As shown in Figure 1 and Figure 2, this embodiment has a microporous ceramic filter with an ultrasonic cleaning device, including an ultrasonic power supply, a filter housing that can withstand pressure, and a microporous ceramic filter element installed in the housing And the ultrasonic vibrator 25 mounted on the housing.

[0026] Described ultrasonic power supply and ultrasonic vibrator 25 are because of adopting known technology, so do not draw ultrasonic power supply among the figure, and ultrasonic vibrator 25 also do not draw detailed diagram. The ultrasonic vibrator 25 and the body 14 adopt a structure that can ensure the sealing of the filter housing and does not hinder the vibration of the ultrasonic vibrator 25 . The structure includes an ultrasonic vibrator box 26, an ultrasonic vibrator 25, a flexible seal 27, a screw 28 and an ultrasonic vibrator seat 16. The ultrasonic vibrator seat 16 is provided with a screw hole and a through hole that can...

Embodiment 2

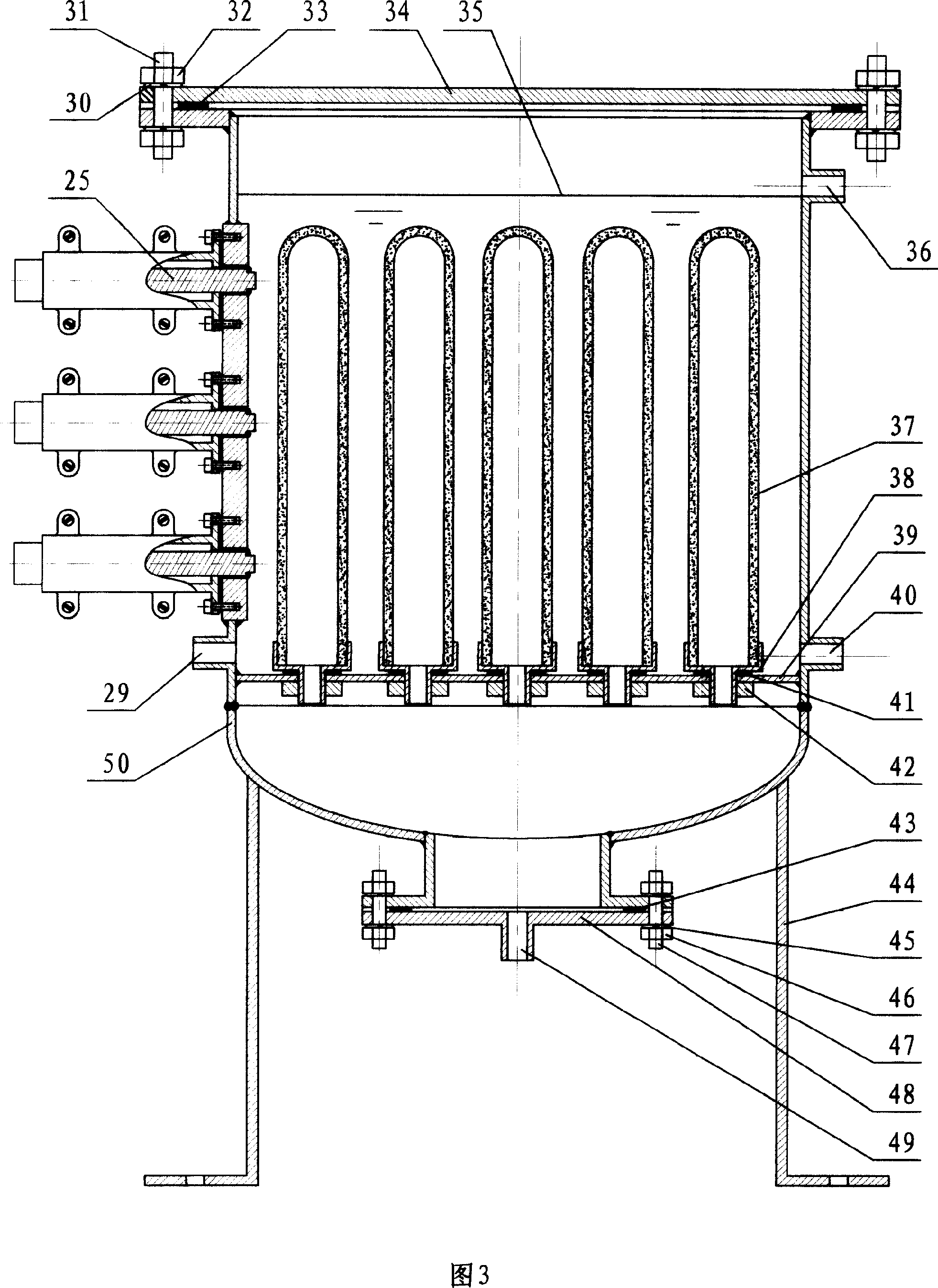

[0029] Embodiment 2: As shown in Fig. 3, the present embodiment has a microporous ceramic filter with an ultrasonic cleaning device, including an ultrasonic power supply, a filter housing that can withstand pressure, a microporous ceramic filter element installed in the housing, and a microporous ceramic filter installed in the housing. The ultrasonic vibrator 25 on the body.

[0030] The ultrasonic power supply and the ultrasonic vibrator are the same as those in the first embodiment, the ultrasonic vibrator is arranged on the side wall of the filter housing, and the installation method of the ultrasonic vibrator and the housing is also the same as that in the first embodiment, which will not be repeated here.

[0031] The filter housing is composed of a body 50 and a head 34. The head 34 can be a flat head, an elliptical head, a dished head, or a spherical head. The present embodiment adopts a flat head; the body 50 and the head 34 are sealed and fixedly connected by the sea...

Embodiment 3

[0033] Embodiment 3: As shown in FIG. 4 , the ultrasonic vibrator 25 of this embodiment is arranged on the head, and the ultrasonic waves emitted by the ultrasonic vibrator 25 first pass through the air and then enter the liquid, and the rest of the requirements are the same as those of the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com