Method for producing Bi-series high-temperature superconductive wire

A high-temperature superconductivity, wire technology, applied in the usage of superconductor elements, superconducting/high-conducting conductors, superconducting devices, etc., can solve problems such as complicated methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Heat treatment of the rolled wire.

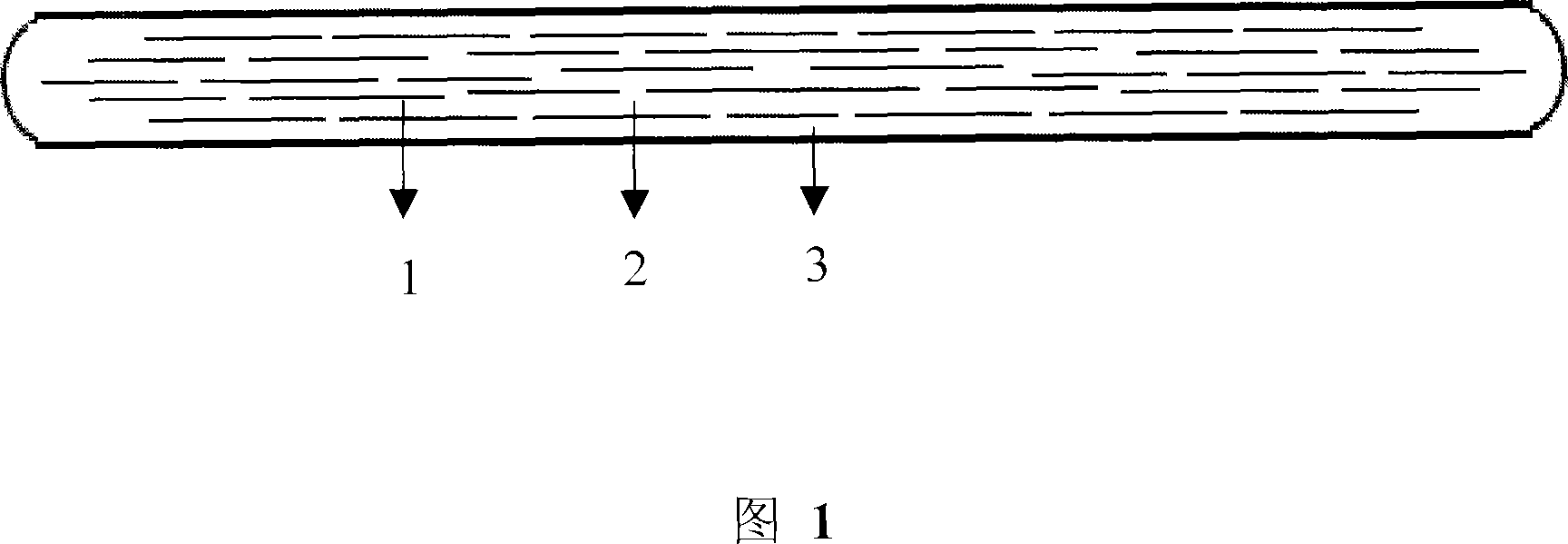

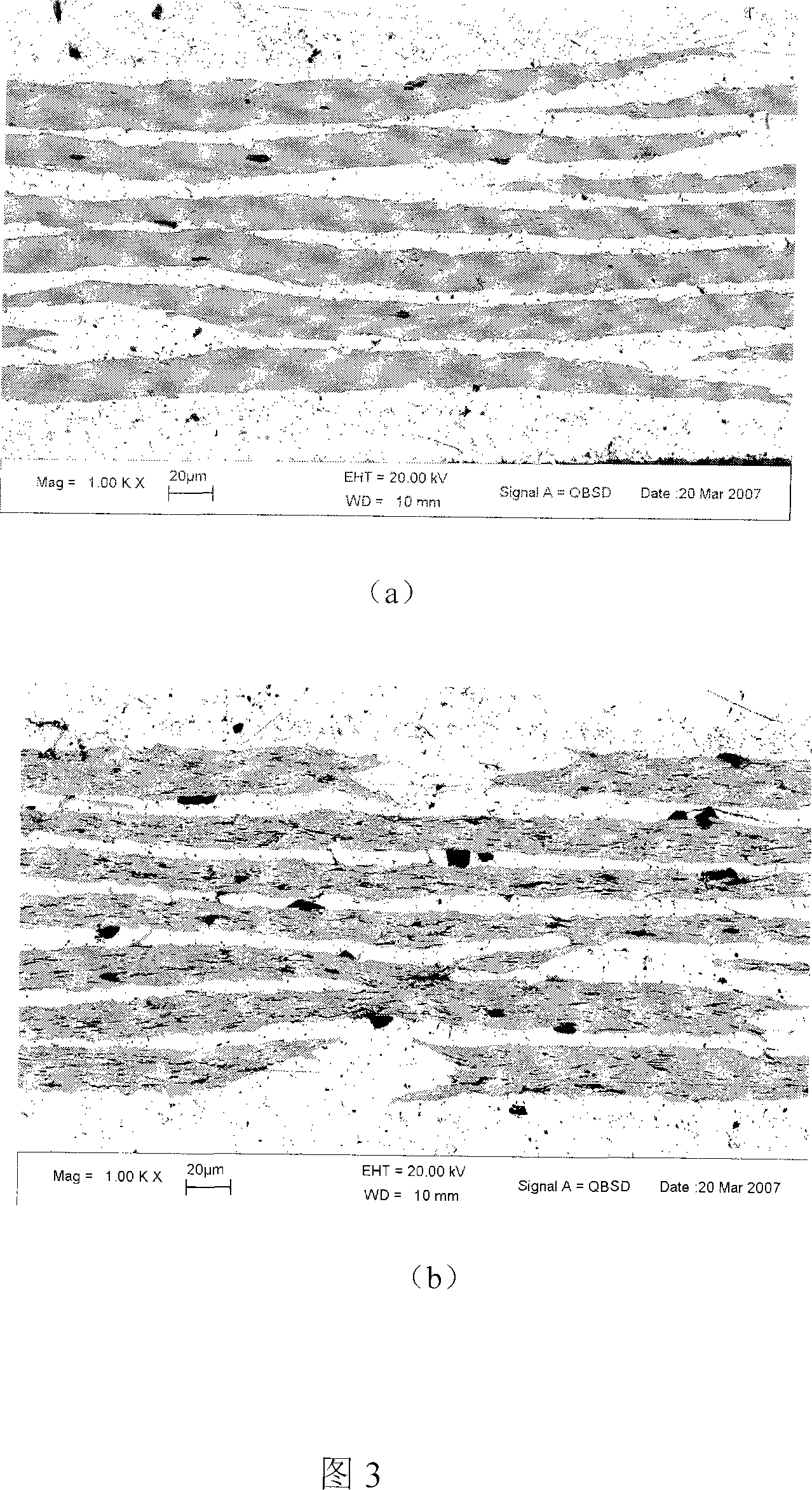

[0039] The structural diagram of the 61-core superconducting wire whose main phase is BSCCO-2223 after rolling is shown in Figure 1, in which 1 is the superconducting core, 2 is pure silver, and 3 is silver-magnesium-nickel alloy. The above samples are divided into There are 16 types, 4 samples for each type, and the length of the samples is 4cm, and then put them into the high temperature and high pressure equipment respectively. Firstly, under different total pressure and different oxygen partial pressure conditions, the temperature is raised from room temperature to different holding temperature, and the temperature is lowered to room temperature after holding for different time.

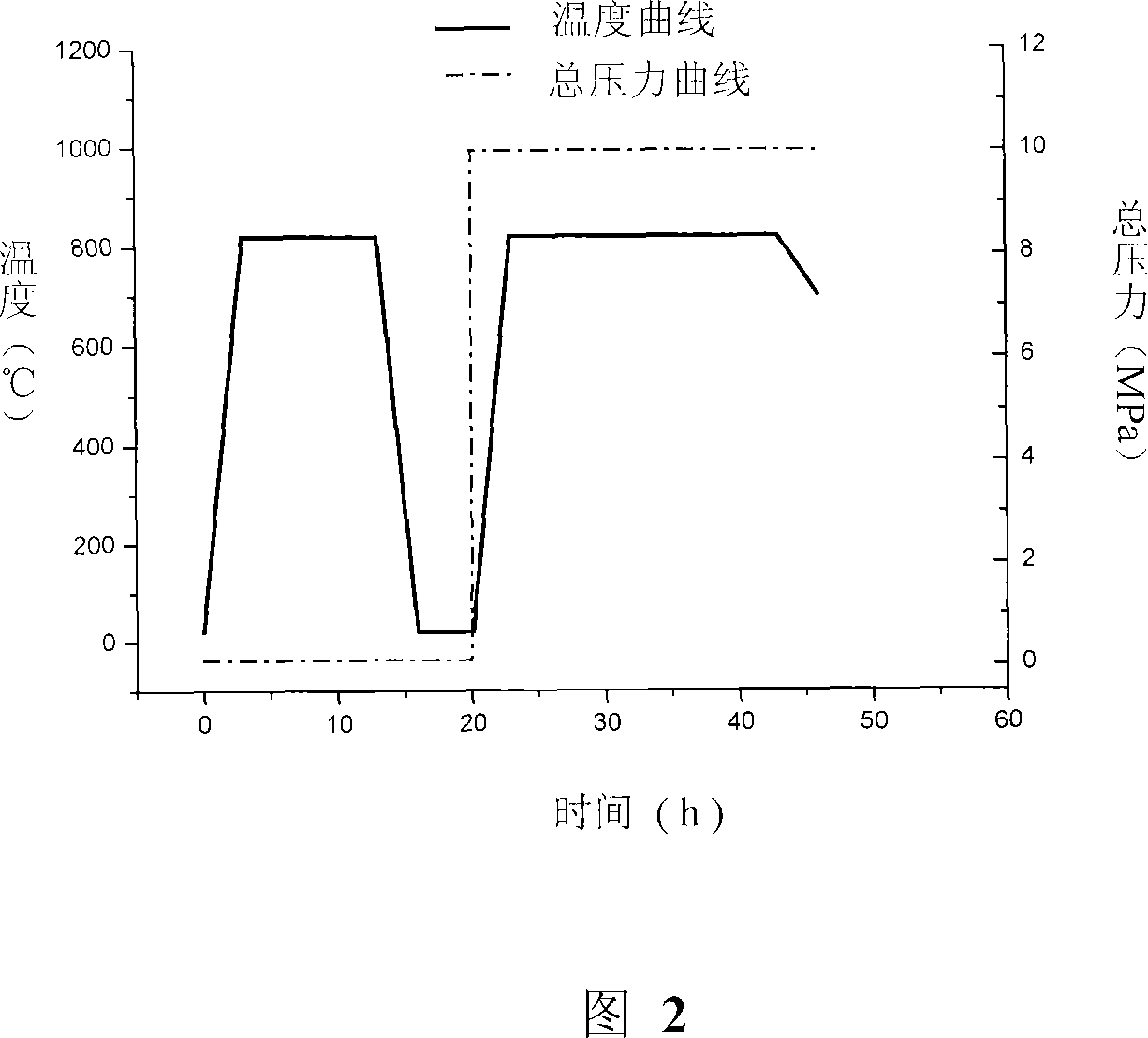

[0040] The wire prepared above was pressurized to 10MPa at room temperature, heated to 825°C and kept for 20 hours, and finally cooled to room temperature. During the high pressure process, the total pressure is always kept at 10MPa, while the oxygen p...

Embodiment 2

[0045] Heat treatment of the rolled wire. The 61-core superconducting wires whose main phase is BSCCO-2223 after rolling were divided into 12 types, with 4 samples for each type, and the length of each sample was 1m, and then put into high-temperature and high-pressure equipment respectively. First, under the conditions of normal pressure and oxygen partial pressure of 0.01 MPa, it is heated to 830° C. and kept for 10 hours, and then cooled to room temperature.

[0046] Pressurize the wires prepared above to different total pressures at room temperature, and perform high-pressure heat treatment under the conditions of different oxygen partial pressures, holding temperatures and holding times. During the high pressure process, the total pressure and oxygen partial pressure are always kept constant.

[0047] The performance indicators of the final wire are shown in Table 2.

[0048] High pressure heat treatment process

Embodiment 3

[0050] Heat treatment of drawn wires.

[0051] The schematic diagram of the structure of the single-core superconducting wire whose main phase is BSCCO-2212 after drawing is shown in Figure 4. The cross-section of Type 3 samples is shown as a circle in Figure 4(a), and the cross-section of Type 2 samples is shown in Fig. Figure 4(b) is an ellipse, in which 1 is a superconducting core, and 2 is pure silver. The length of the above-mentioned samples is 2m, and they are respectively put into high-temperature and high-pressure equipment. Firstly, under normal pressure and an oxygen partial pressure of 0.009MPa, the temperature is raised from room temperature to different holding temperatures, and then cooled to room temperature after holding for 8 hours.

[0052] The wire prepared above was pressurized to 10MPa at room temperature, heated to 825°C and kept for 20 hours, and finally cooled to room temperature. In the process of high pressure, the total pressure is always maintaine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com