A kind of mud for repairing semi-finished sanitary ware and its preparation method

A technology of sanitary ware and semi-finished products, applied in the field of ceramic production, can solve problems such as insufficient compactness, easy cavity, and influence on product market sales, and achieve the effect of dense and firm repair parts, easy sliding, and smooth movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

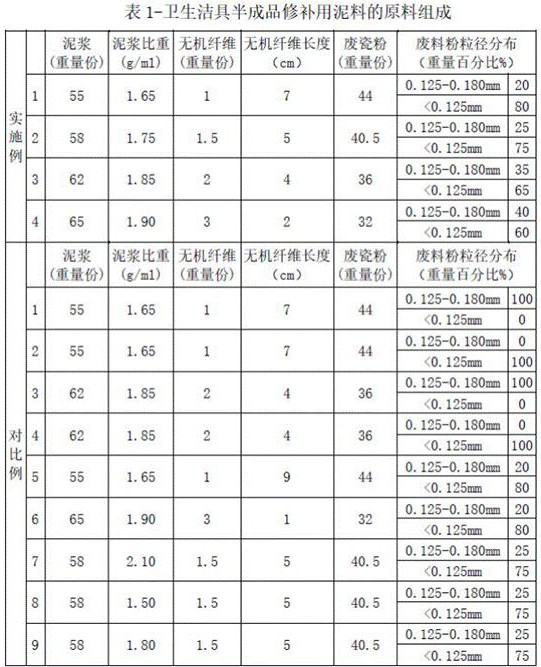

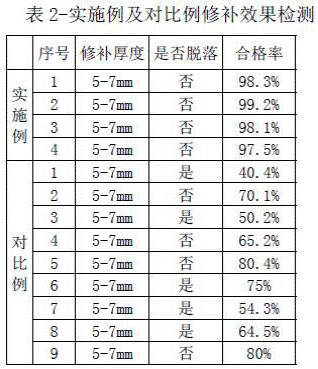

Embodiment 1-4 and comparative example 1-8

[0046] Embodiment 1-4 and comparative example 1-8 prepare sanitary ware semi-finished product repair mud material according to the following steps:

[0047] Step 1, weighing according to the proportion, wherein, then adding mud and stirring the mud;

[0048] Step 2. Add the inorganic fiber three times, and keep stirring, so that the inorganic fiber is evenly dispersed in the mud;

[0049] Step 3. Add the waste porcelain powder three times and stir until uniform;

[0050] In steps 2 and 3, the stirring blades of the stirrer perform plane reciprocating and circular translation to stir the mud, inorganic fibers and waste porcelain powder.

[0051] In step 1, the stirring speed of the mud is 80r / min, in steps 2 and 3, the linear speed of stirring is 5cm / s, and the angular speed is 1rad / s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com