Printed circuit board unit

A technology of printed circuit boards and printed circuit boards, which is applied in the direction of printed circuits, printed circuits, printed circuit manufacturing, etc., and can solve the problems of time-consuming bending of wires and increased production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] FIG. 1 schematically shows a server computer 11 as a specific example of electronic equipment according to an embodiment of the present invention. The server computer 11 is mounted on a rack, for example. The server computer 11 includes a housing 12 . A printed circuit board unit or motherboard unit is housed within the housing 12 .

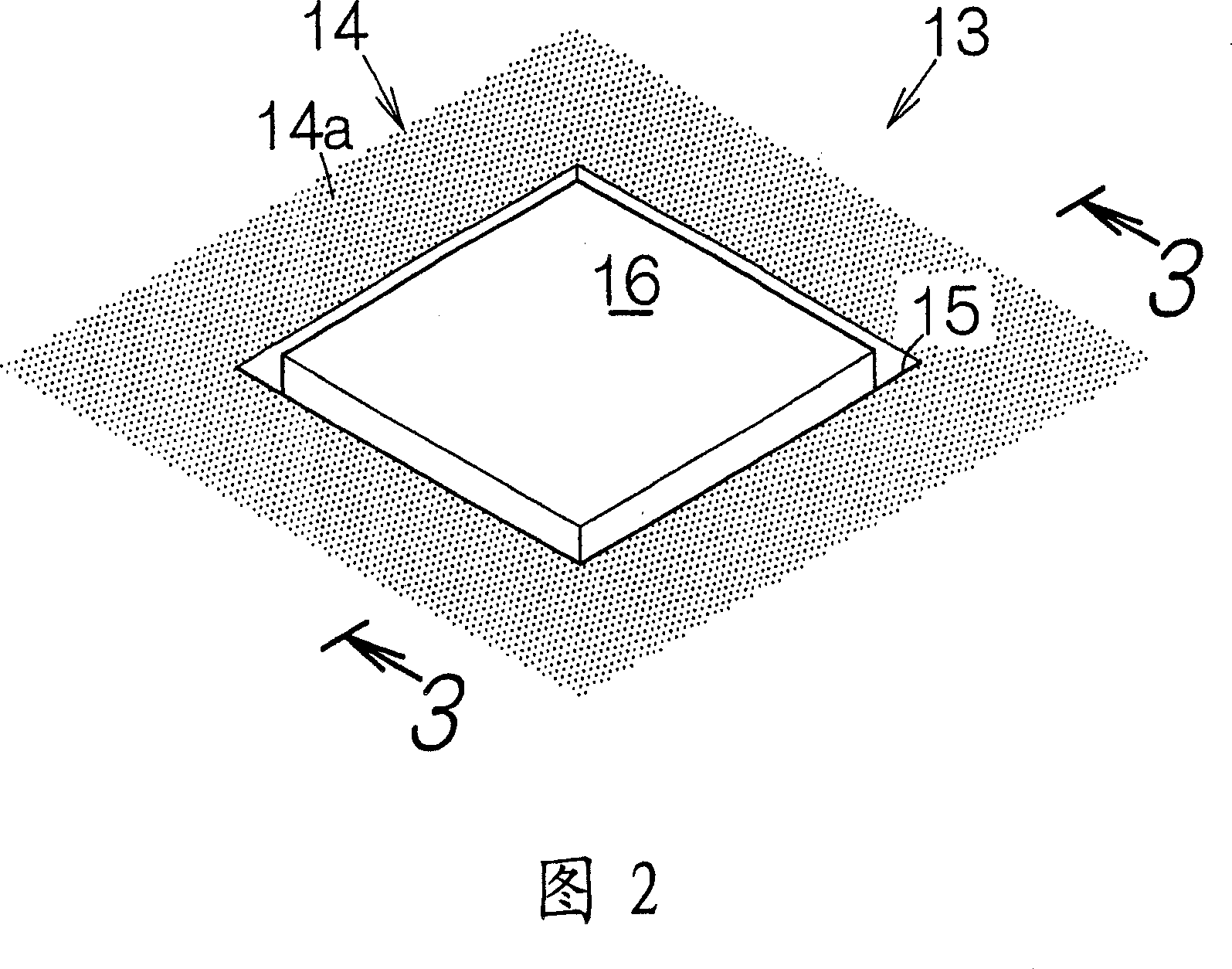

[0030] As shown in FIG. 2 , the motherboard unit 13 includes a printed wiring board 14 . The printed wiring board 14 includes a substrate 14a. A recess 15 is formed in the front surface of the substrate 14a. The depression 15 forms, for example, a cuboid-shaped space. Electronic components or large scale integration (LSI) chips 16 are accommodated in the recess 15 . The LSI chip 16 is a so-called Insert Mounted Device (IMD).

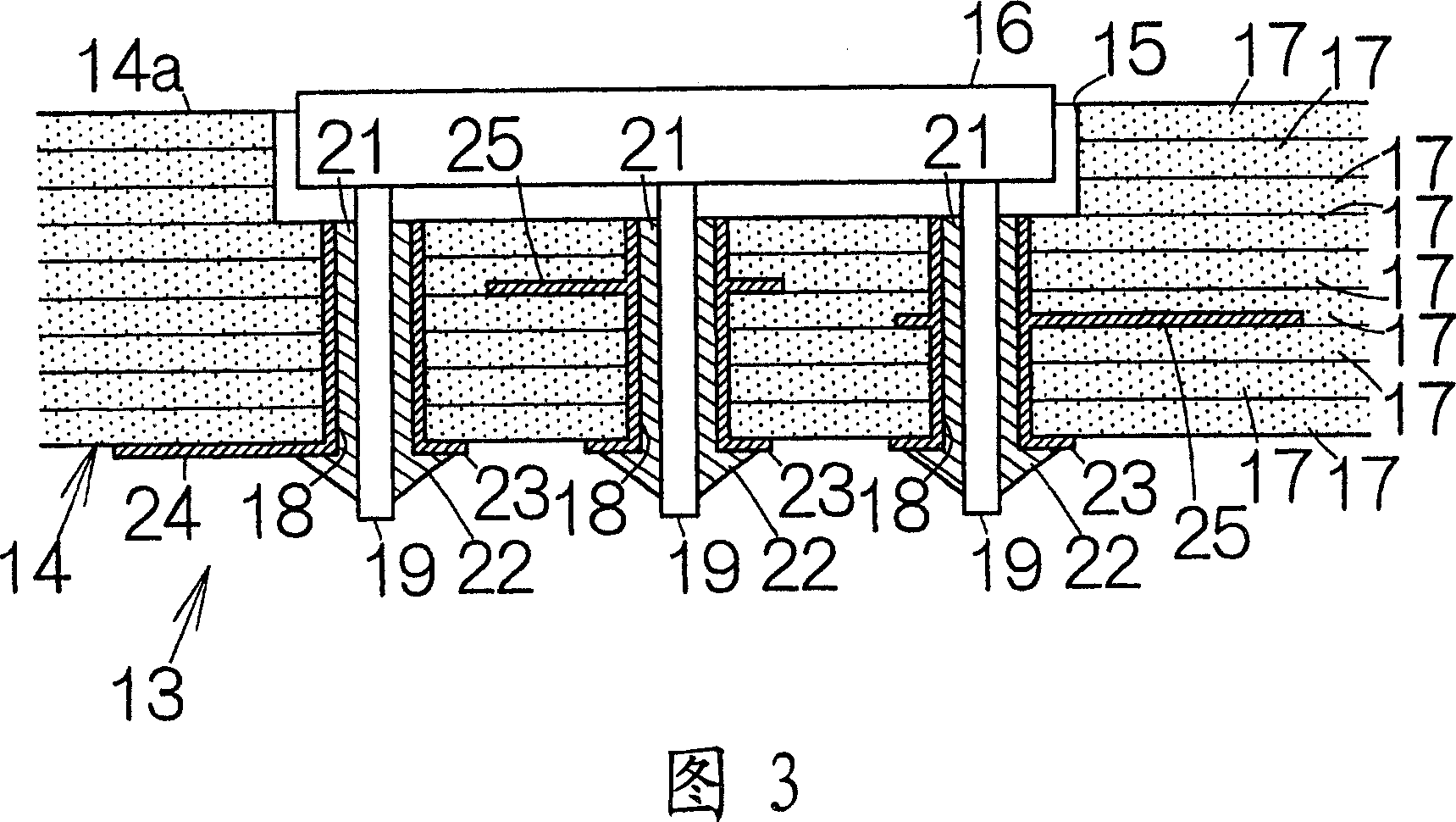

[0031] As shown in FIG. 3 , the substrate 14 a has a layered structure including a plurality of insulating layers 17 . The insulating layer 17 can be made of a resin material, for example. For example, a thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com