Board joint method of dual-side printed circuit board

A printed circuit board and double-sided printing technology, which is applied in the direction of assembling printed circuits, electrical components, electrical components, etc., can solve the problems of waste, low production efficiency, and time-consuming, etc., to reduce production costs and simplify Mounting process, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

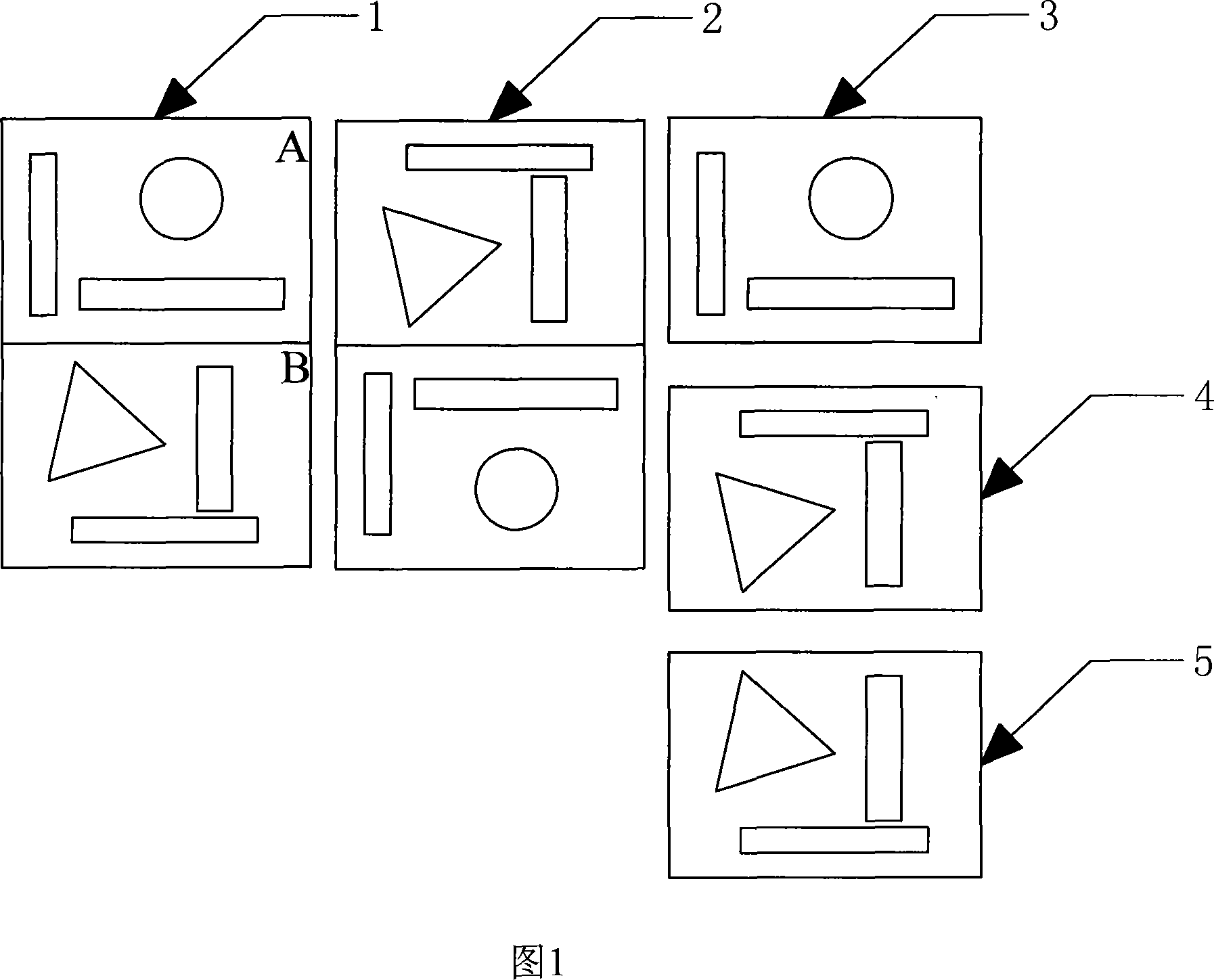

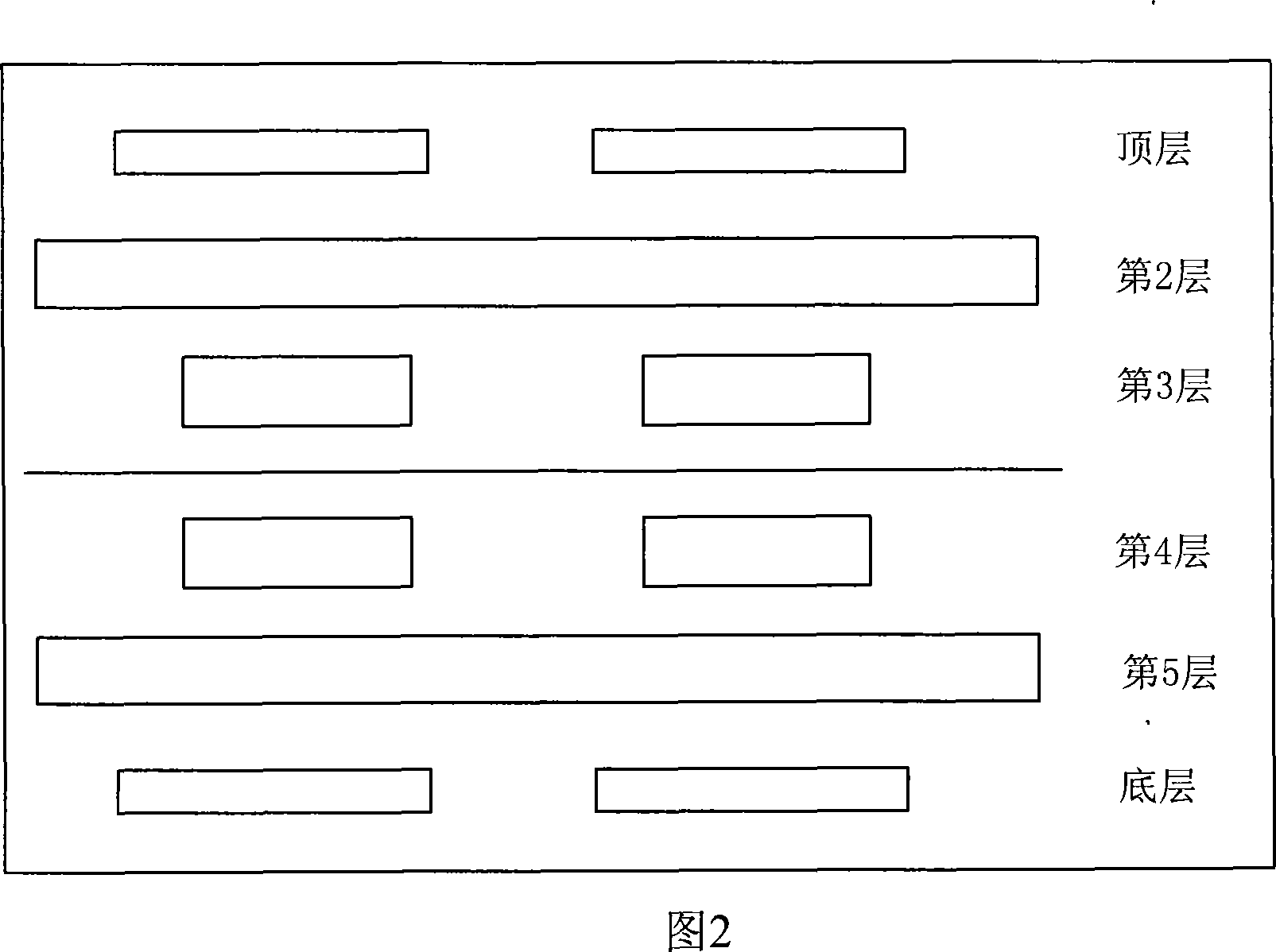

[0031] See Figure 1. In the figure, figure 3 is the bottom figure of the printed circuit board with smaller size, figure 4 is the top layer figure of the printed circuit board with smaller size, and figure 5 is the mirror image of figure 4 in the horizontal direction. In the figure, place figure 3 at position A, and figure 5 at position B, that is, figure 3 and figure 5 are spliced horizontally (the splicing direction can be determined according to the printed circuit board) to obtain figure 1, which constitutes a larger printed circuit board Figure 1 is mirrored in the horizontal direction to obtain Figure 2, which is the bottom layer figure of the larger printed circuit board.

[0032] In Fig. 1, only the splicing situation of producing two smaller-sized double-sided printed circuit boards at a time is shown. According to the splicing method described above, larger printed circuit boards can be obtained, and more smaller printed circuit boards can be produced at one time....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com