End profile on slide bearing complementary elements for reducing surface pressure

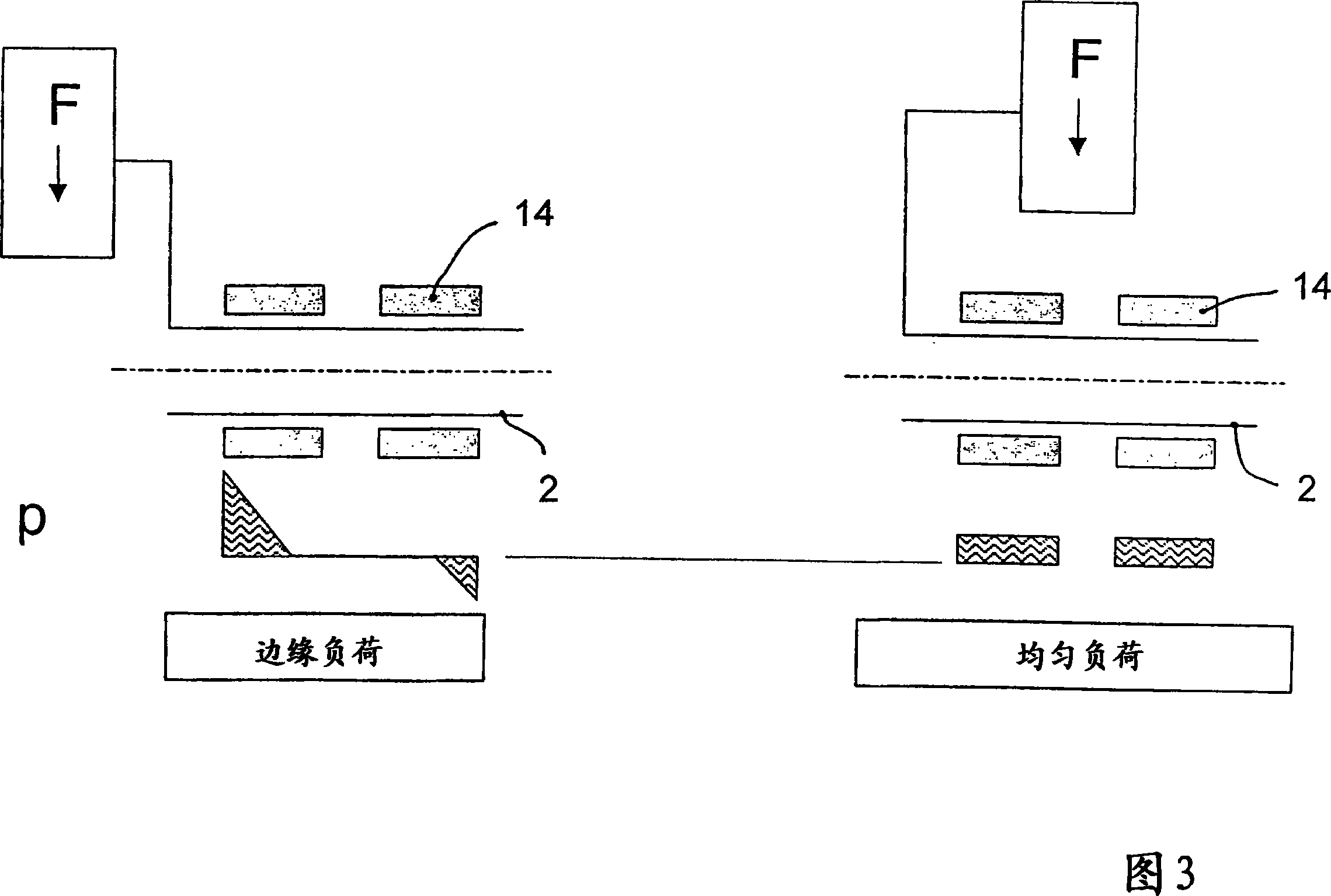

一种端部成型、轮廓结构的技术,应用在滑动接触轴承、旋转运动的轴承、抗离心力的转动部件等方向,能够解决成本和使用寿命影响、滑动轴承使用寿命短等问题,达到提高使用寿命、磨损现象减小、使用寿命提高的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

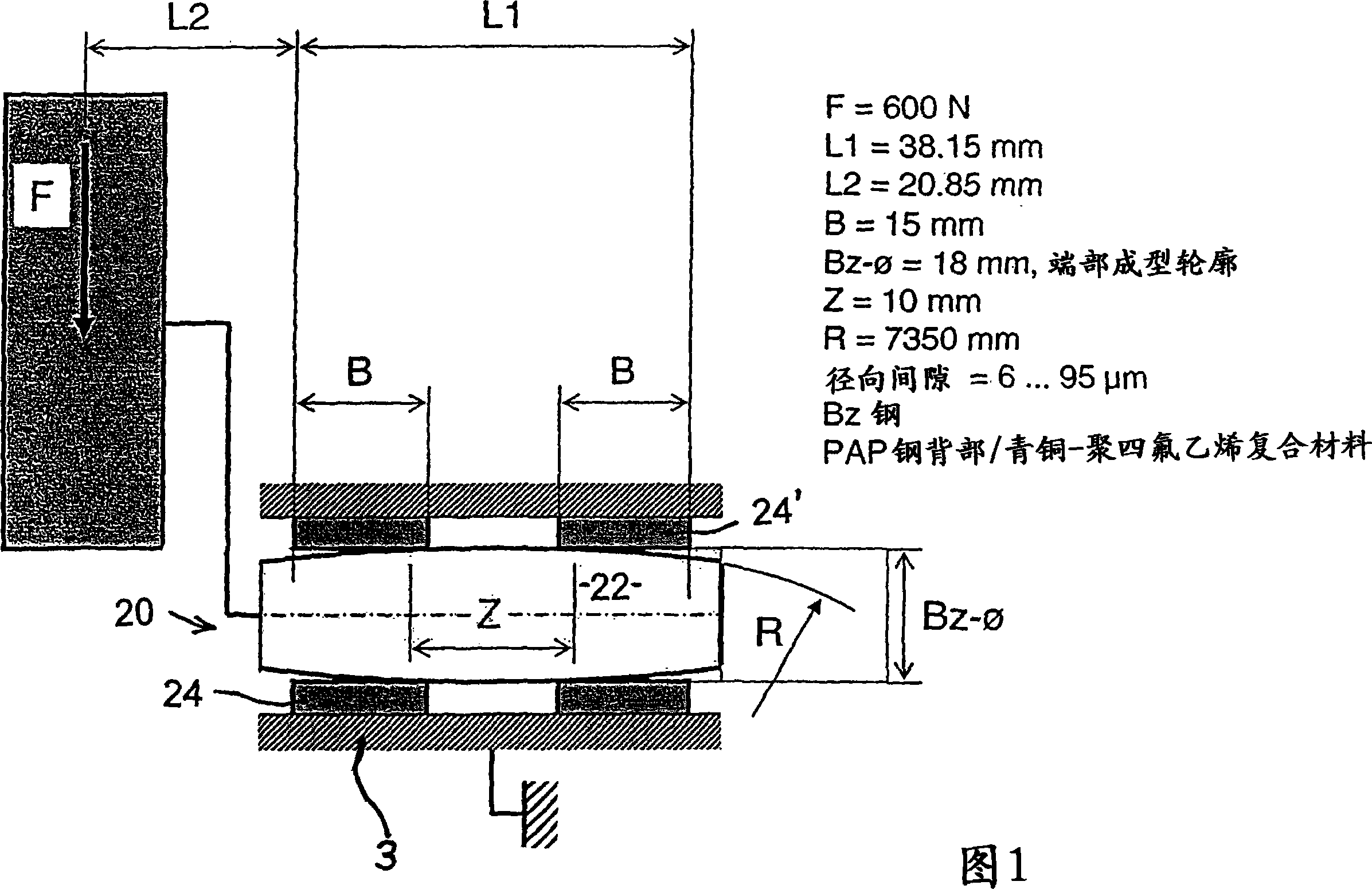

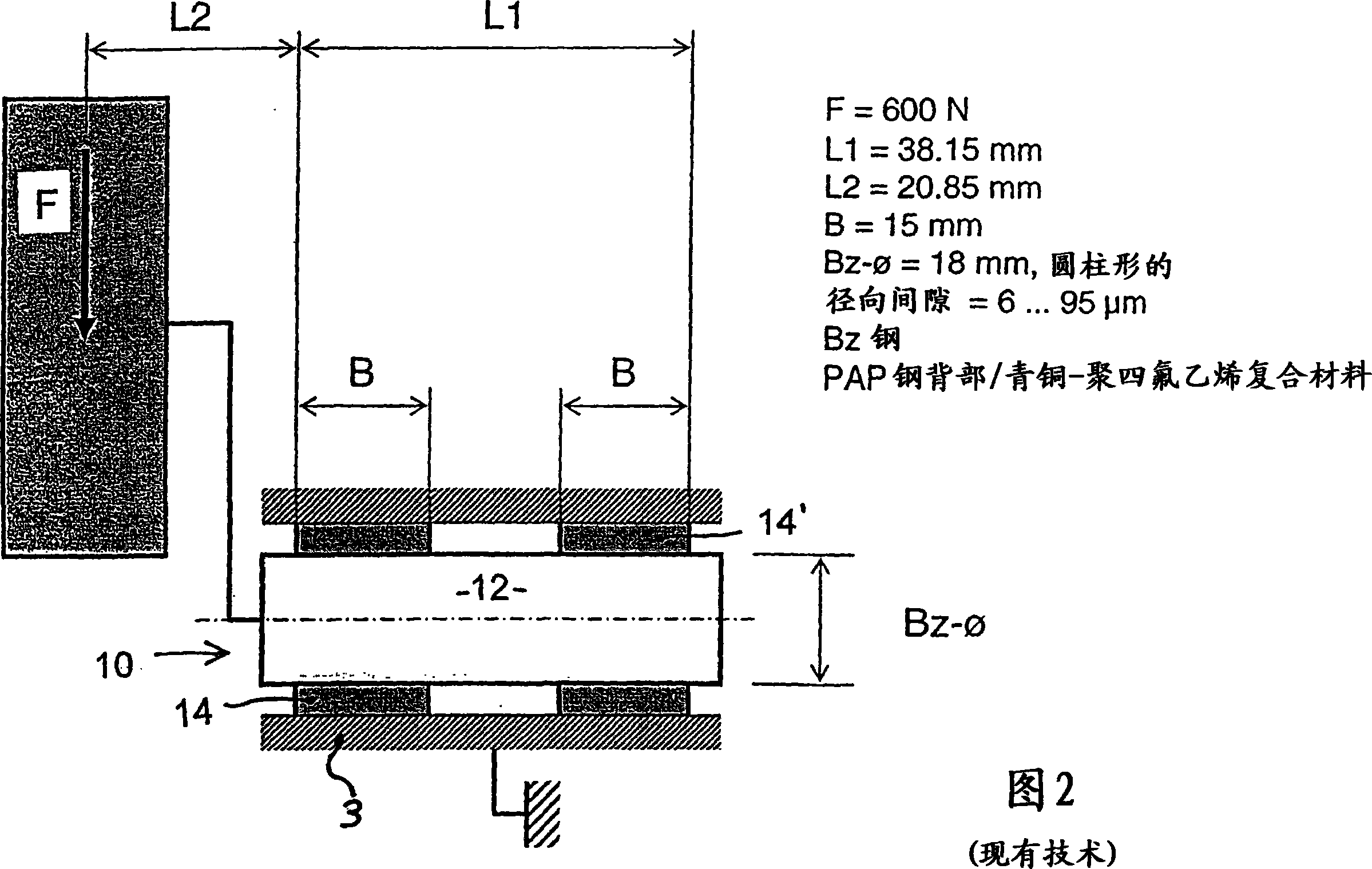

[0027] FIG. 4 therefore shows a cross section through a belt tensioning system 1 with eccentrically arranged tensioning pulleys. The belt tensioning system 1 comprises a lower cylindrical housing 3 and an upper cylindrical housing 5 which have an outer diameter and an inner diameter which are as equal as possible. The cylindrical housings 3 and 5 interact axially in such a way that they can rotate relative to each other about a longitudinal axis 6 . The upper cylindrical housing 5 contains a side-mounted lever 8 , where the tensioning wheel is fastened by a screw 9 .

[0028] The radial inner surface of the upper cylindrical housing 5 is connected in a rotationally fixed manner to the axial end of a hollow pin 2 . The outer pin 2 has a rotationally fixed disk 4 on its other end, a friction plate 13 is arranged on its circular surface towards the lower cylindrical housing 3, and the friction plate 13 is mounted on the upper cylindrical housing 5, During the rotational movemen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com