Adjustable axial piston machine having a bearing shell for the pivot cradle

A technology of axial plunger machine and bearing bush, which is applied in the field of axial plunger machine, can solve problems such as machine failure and bearing bush failure, and achieve the effects of restraining fracture, safe and reliable support, and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

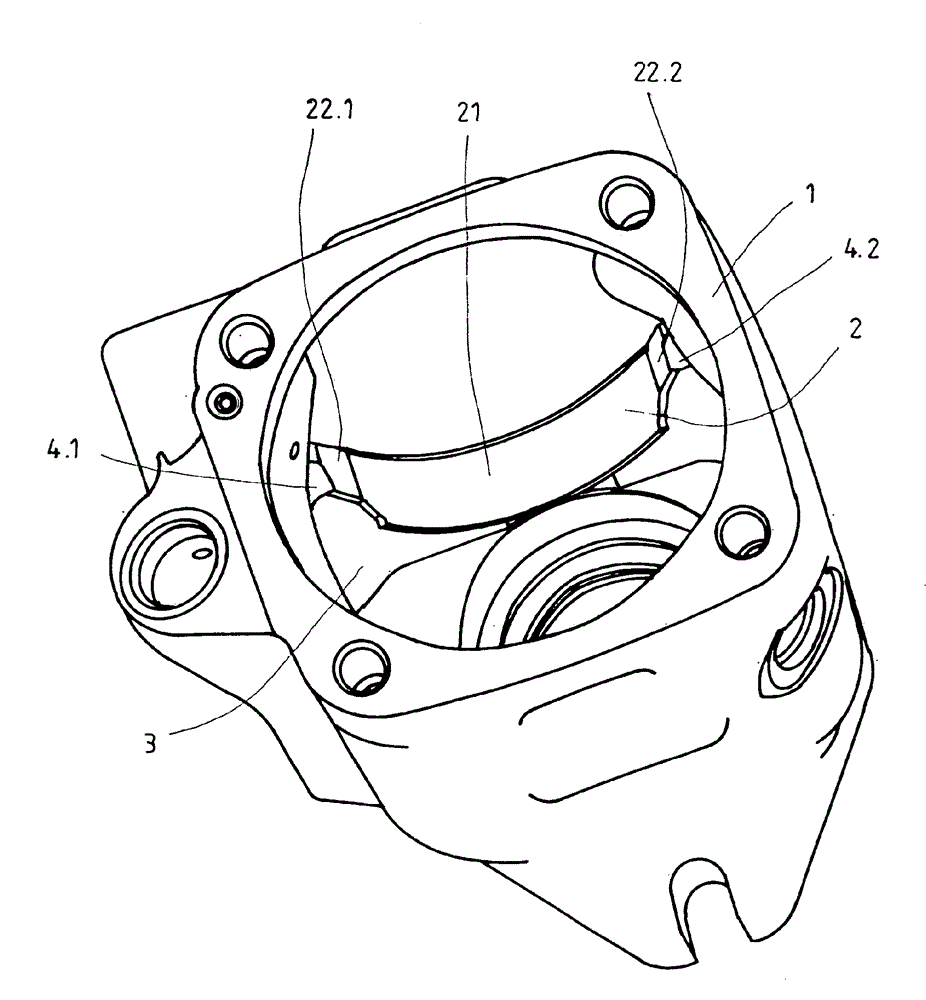

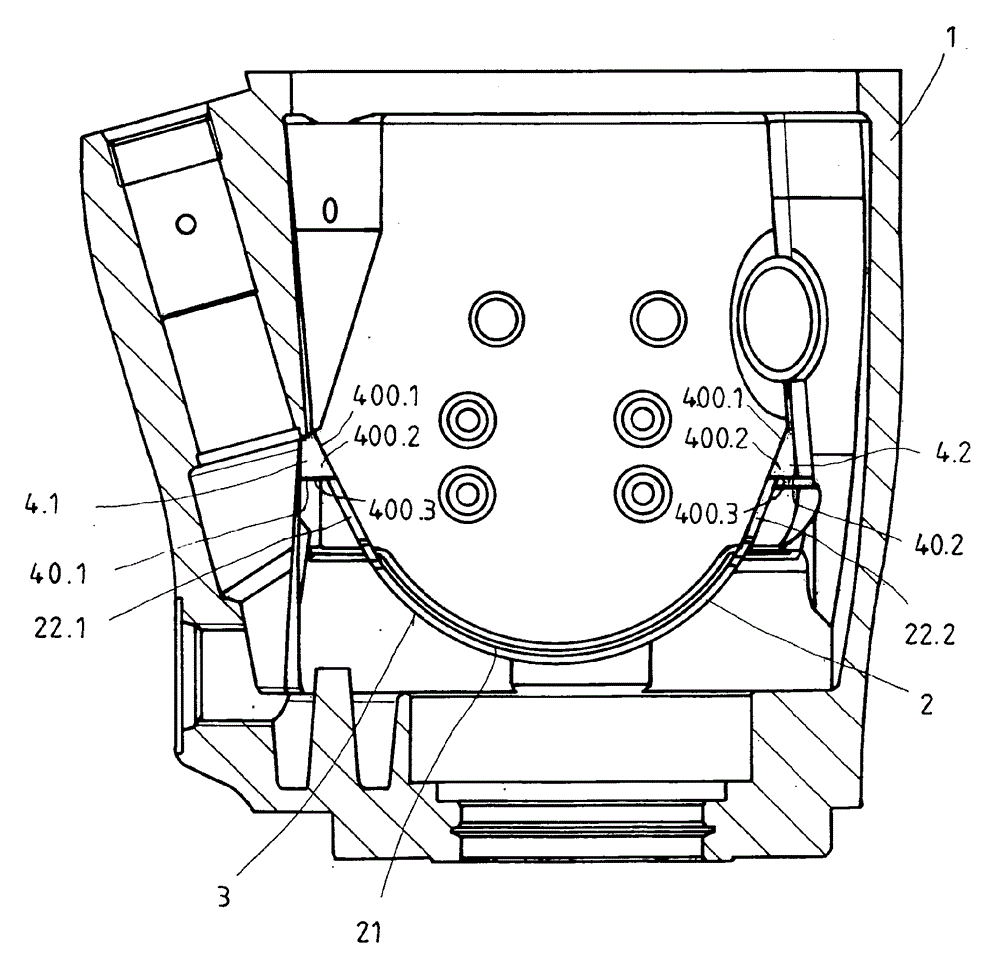

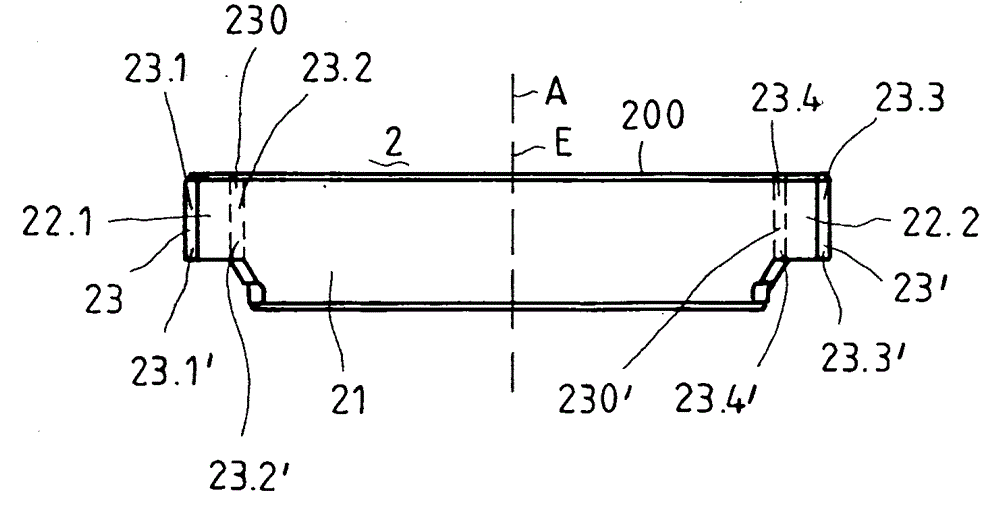

[0025] figure 1 A perspective view of the housing 1 of the adjustable axial piston machine according to the invention is shown. In the housing 1 , a bearing shell 2 is arranged in an interior space 3 . For reasons of clarity, the cradle is not shown. However, the cradle is supported on the housing 1 via the bearing shell 2 in a known manner. The bearing shell 2 has for this purpose an annular segment-shaped bearing segment 21, a straight first bearing shell end region 22. l extending in one plane and a straight second bearing shell end also extending in one plane Area 22.2. The first bearing shell end region 22.1 bears in the event of circumferential forces occurring in the bearing section 21 on first positioning lugs 4.1, which in turn are formed on the housing. The second bearing shell end region 22.2 bears in the event of circumferential forces occurring in the bearing section 21 on a second positioning lug 4.2, which is likewise formed on the housing. The illustrated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com