Cyclone separating device and cyclone separating assembly provided with the same for dust collector

A technology of cyclone separation device and cyclone separator, which is applied in the direction of suction filter, etc., can solve the problems of affecting the separation efficiency and the deterioration of the separation effect of the vacuum cleaner, and achieve the effect of high separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

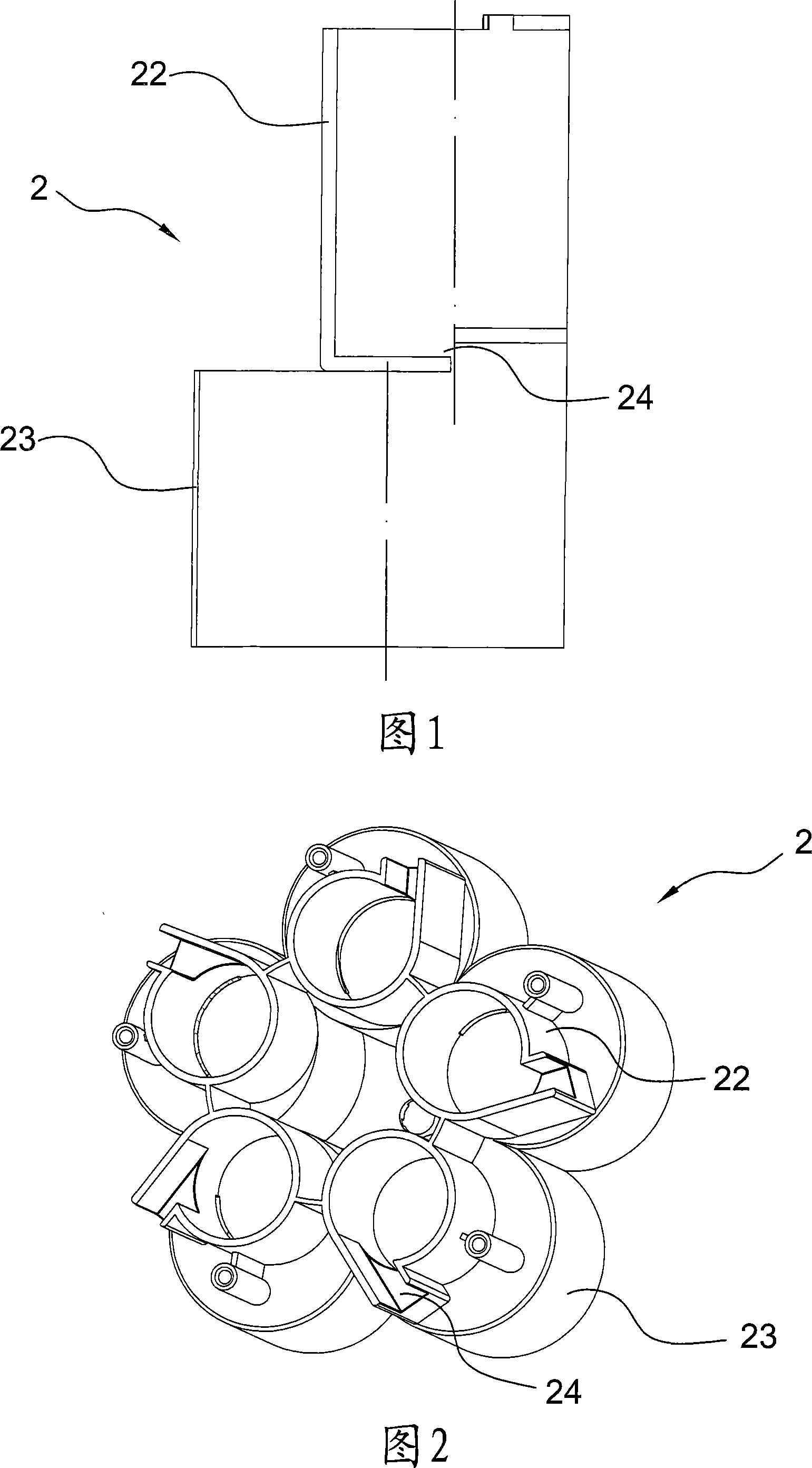

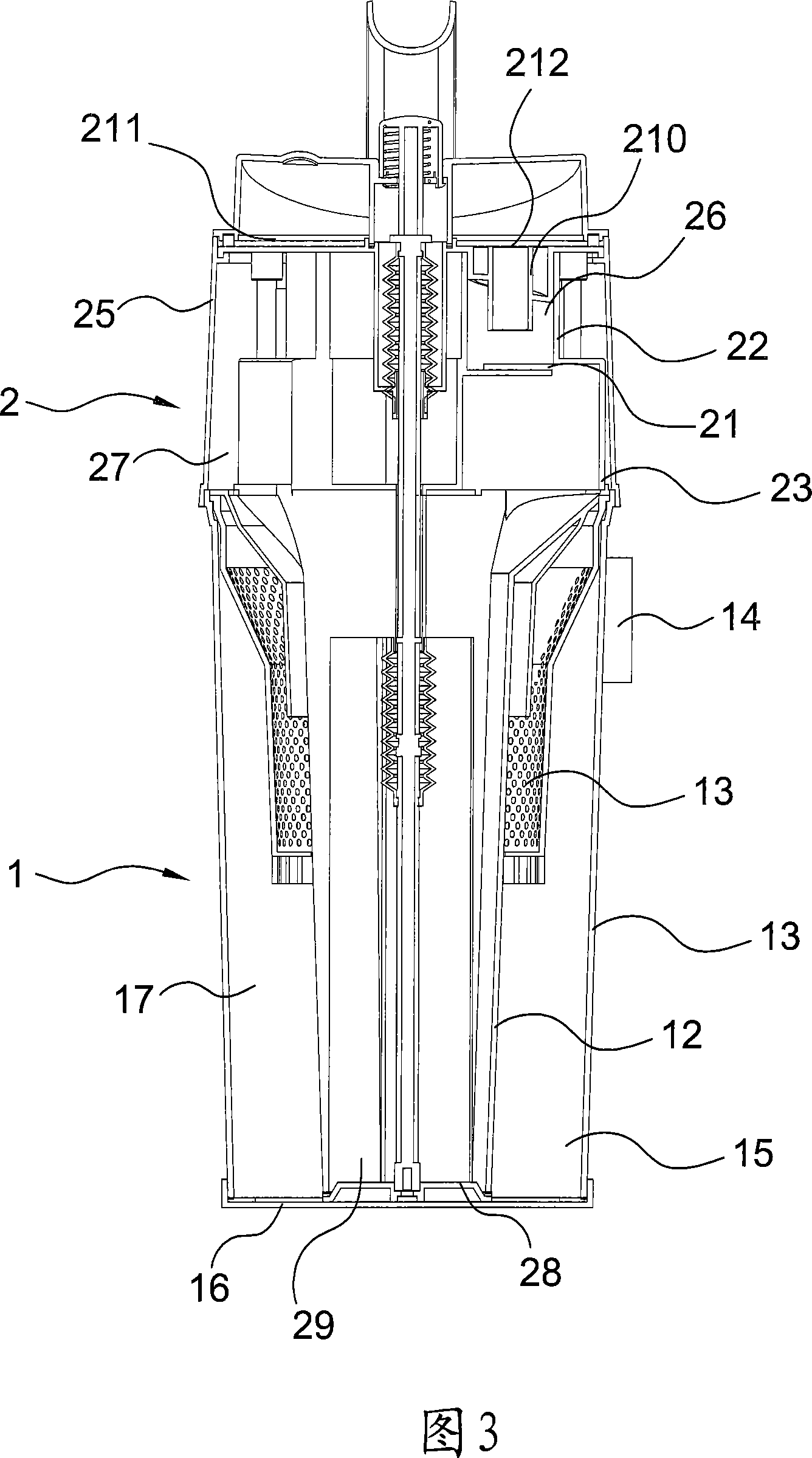

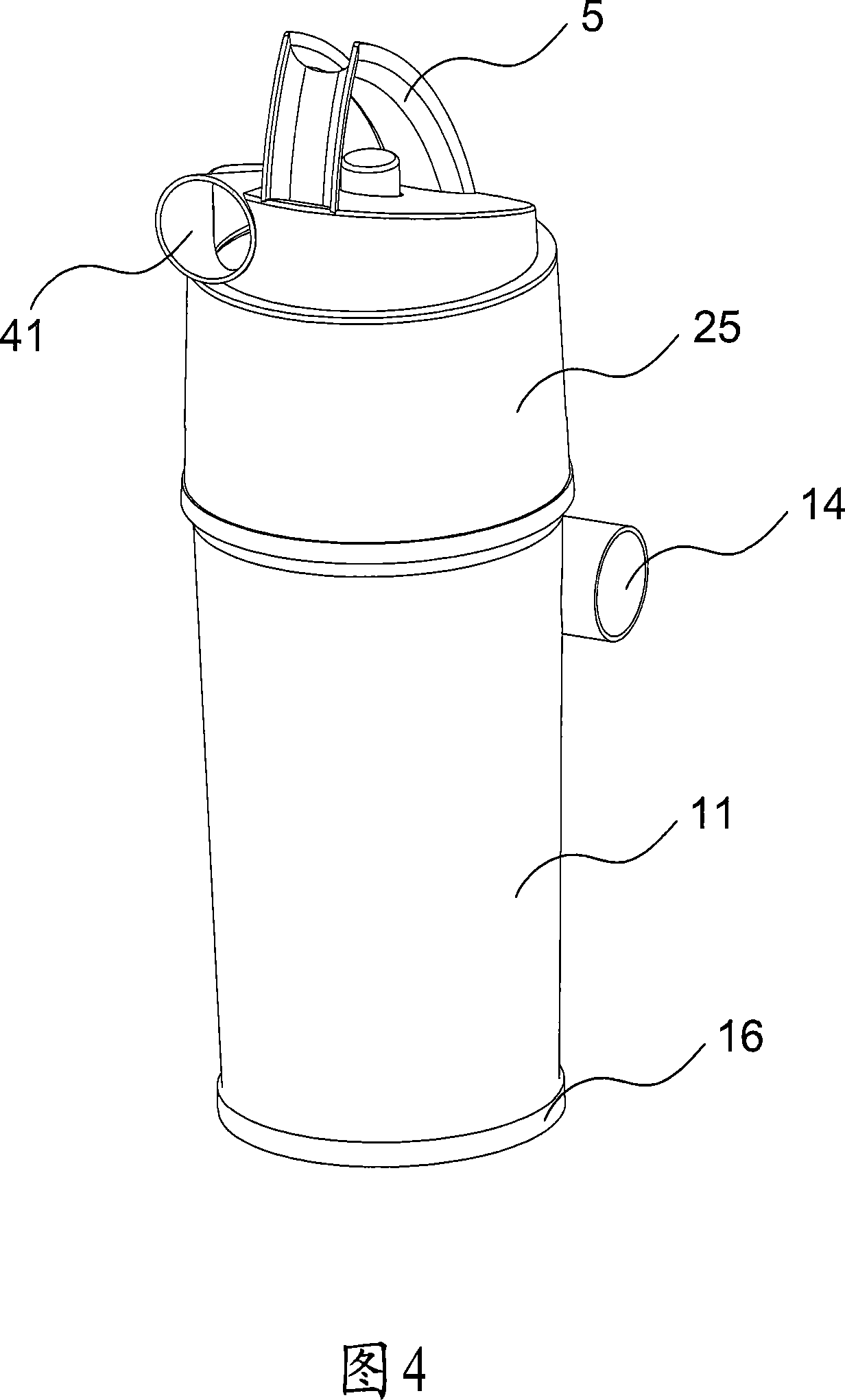

[0024] A cyclone separator 2 as shown in Figures 1-2, the cyclone separator 2 includes a first outer shell 22 with an air inlet 21, a second outer shell 22 connected in series with the first outer shell 21, the first The outer shell 21 and the axis line of the second outer shell 22 deviate from the arrangement, and the first outer shell 22 and the second outer shell 23 are provided with an ash drop port 24 at their junction, and the inner cavity of the first outer shell 22 and the The inner cavity of the second outer casing 23 is connected through the ash-falling opening 24, and the second outer casing 23 has at least a part of the side wall from the ash-falling opening 24 and is arranged in the following structure: the inner wall surface of the part of the side wall reaches the first shell The distance from the body axis is greater than the distance from the inner wall surface of the side wall of the first outer shell 22 to the axis of the first outer shell. As shown in the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com