Electric suction cleaner

A vacuum cleaner and electric technology, applied in the direction of vacuum cleaners, suction nozzles, suction hoses, etc., can solve the problems of non-rotating rotating brushes, inability to obtain air flow, blockage, etc., and achieve the effect of easy operation, low cost and light cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

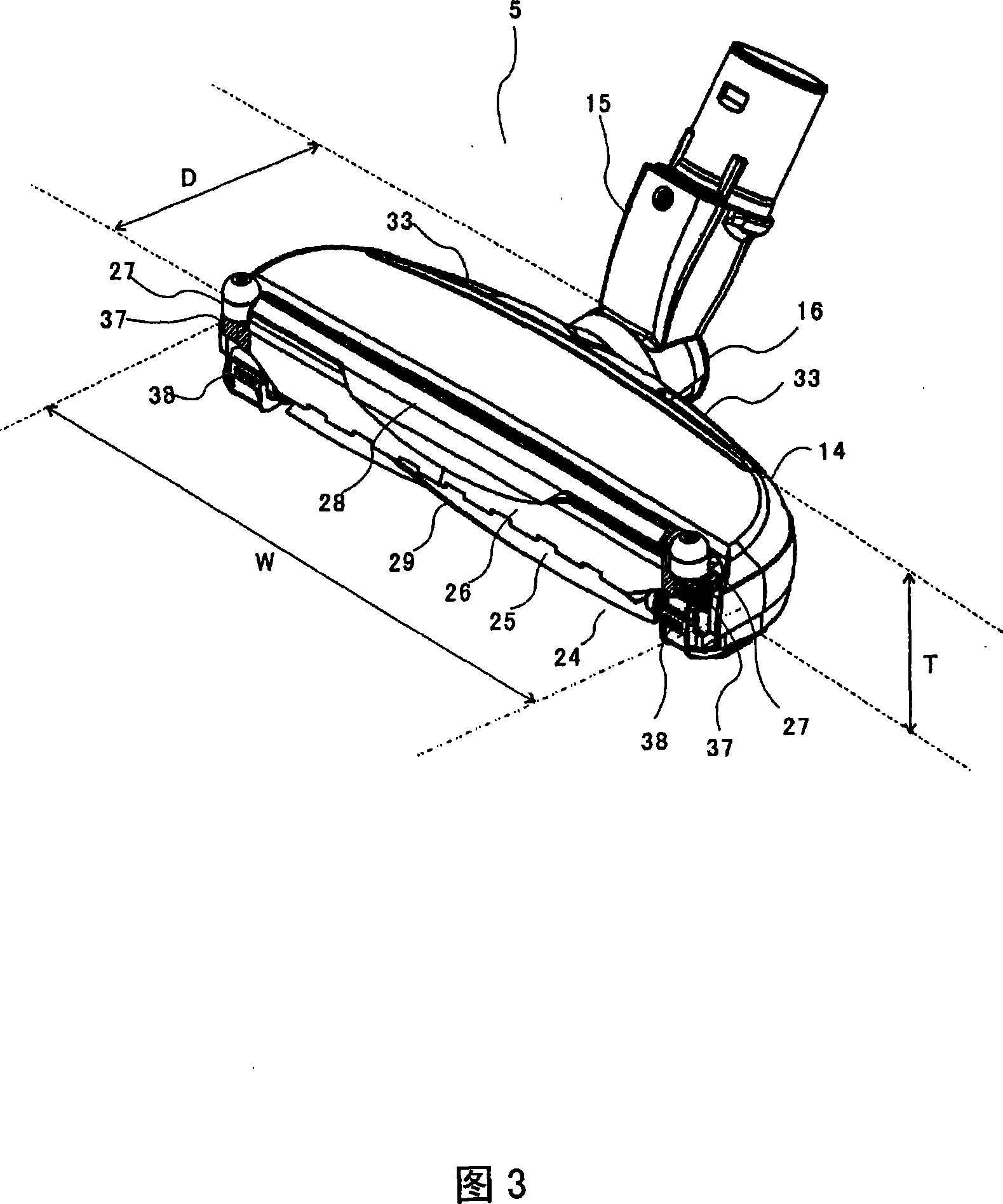

[0037] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings.

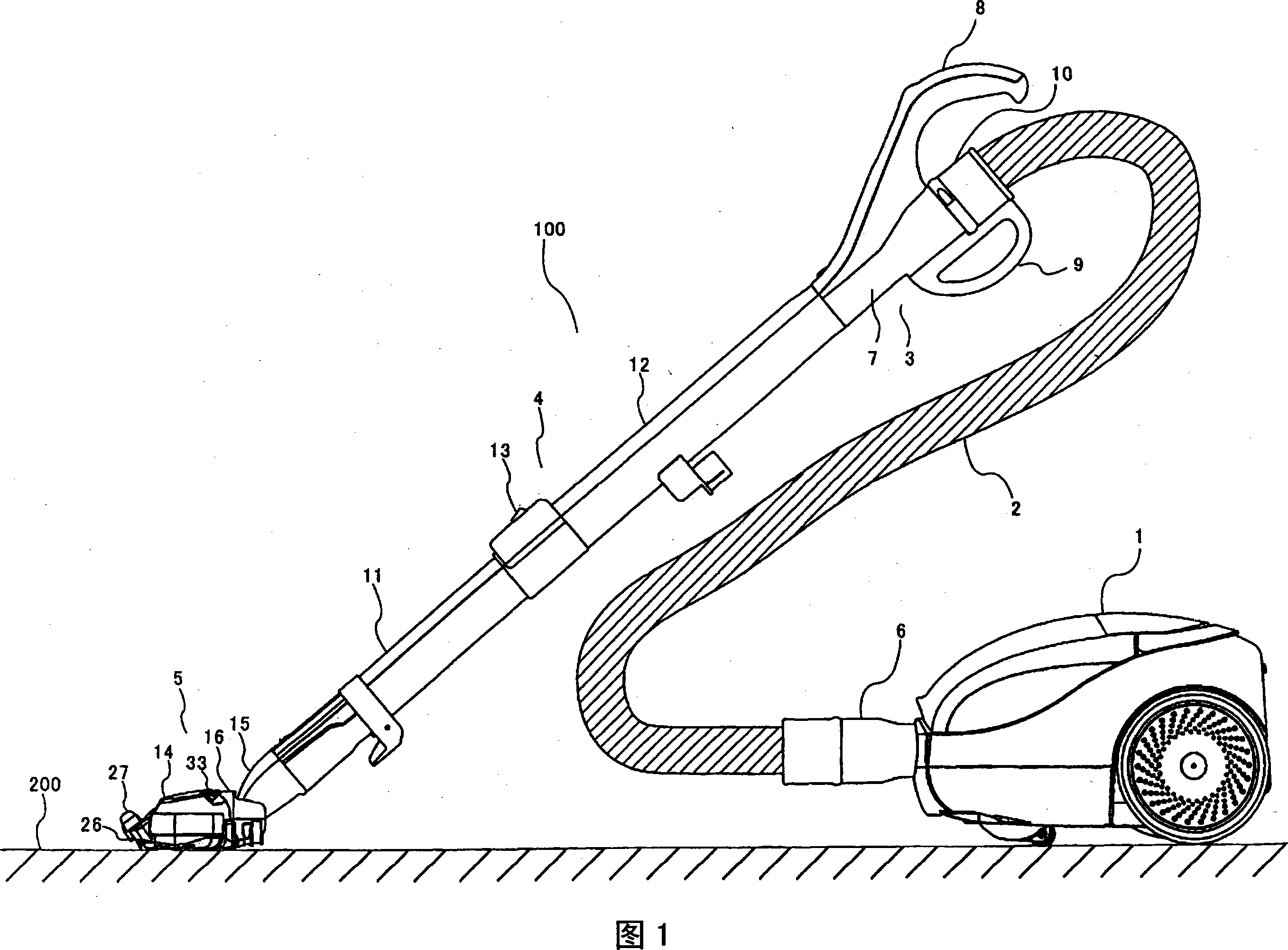

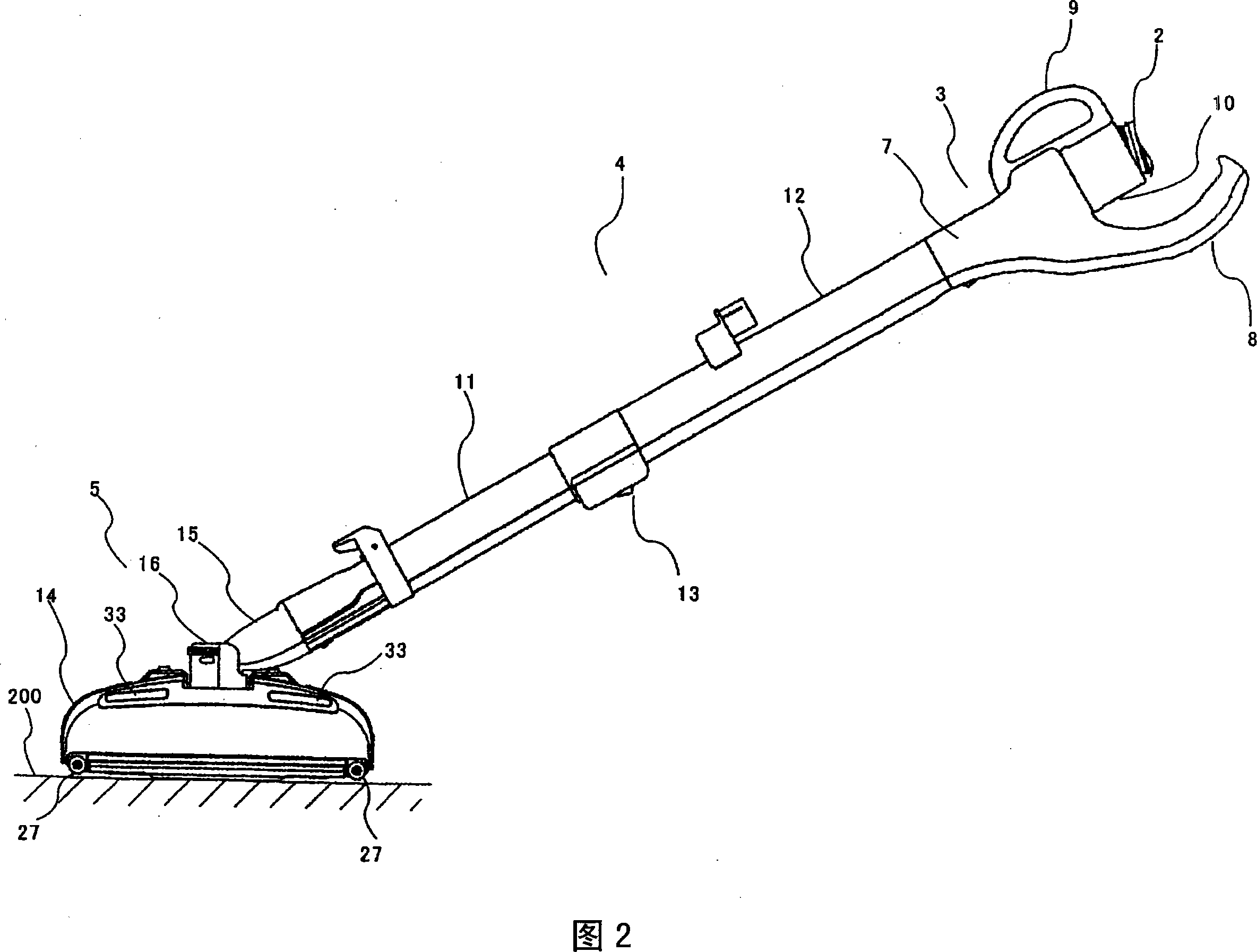

[0038] Fig. 1 is a left side view of an electric vacuum cleaner according to an embodiment of the present invention. Hereinafter, for convenience of description, in FIG. 1, the left side is referred to as the front, the right side is referred to as the rear, the front side is referred to as the left, and the rear side is referred to as the right. , left and right, and up and down, and explain them at the same time.

[0039] This electric vacuum cleaner 100 includes a canister-shaped vacuum cleaner main body 1 , a suction hose 2 , an operation part 3 , a suction pipe 4 , and a suction tool 5 . An electric blower (not shown) is built in the vacuum cleaner main body 1, and suction is generated by the electric blower.

[0040] The connection part 6 attached to the rear end side of the suction hose 2 is detachably connected to the front side of the cleaner main b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com