Flow sensor transducer with dual spiral wheatstone bridge elements

A technology of temperature sensor and heating element, applied in the field of resistance temperature detector, flow sensor and sensor system, which can solve the problem of expensive platinum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific values and configurations discussed in these non-limiting examples may vary and are cited merely to illustrate at least one embodiment and are not intended to limit the scope thereof. In general, the drawings are not drawn to scale.

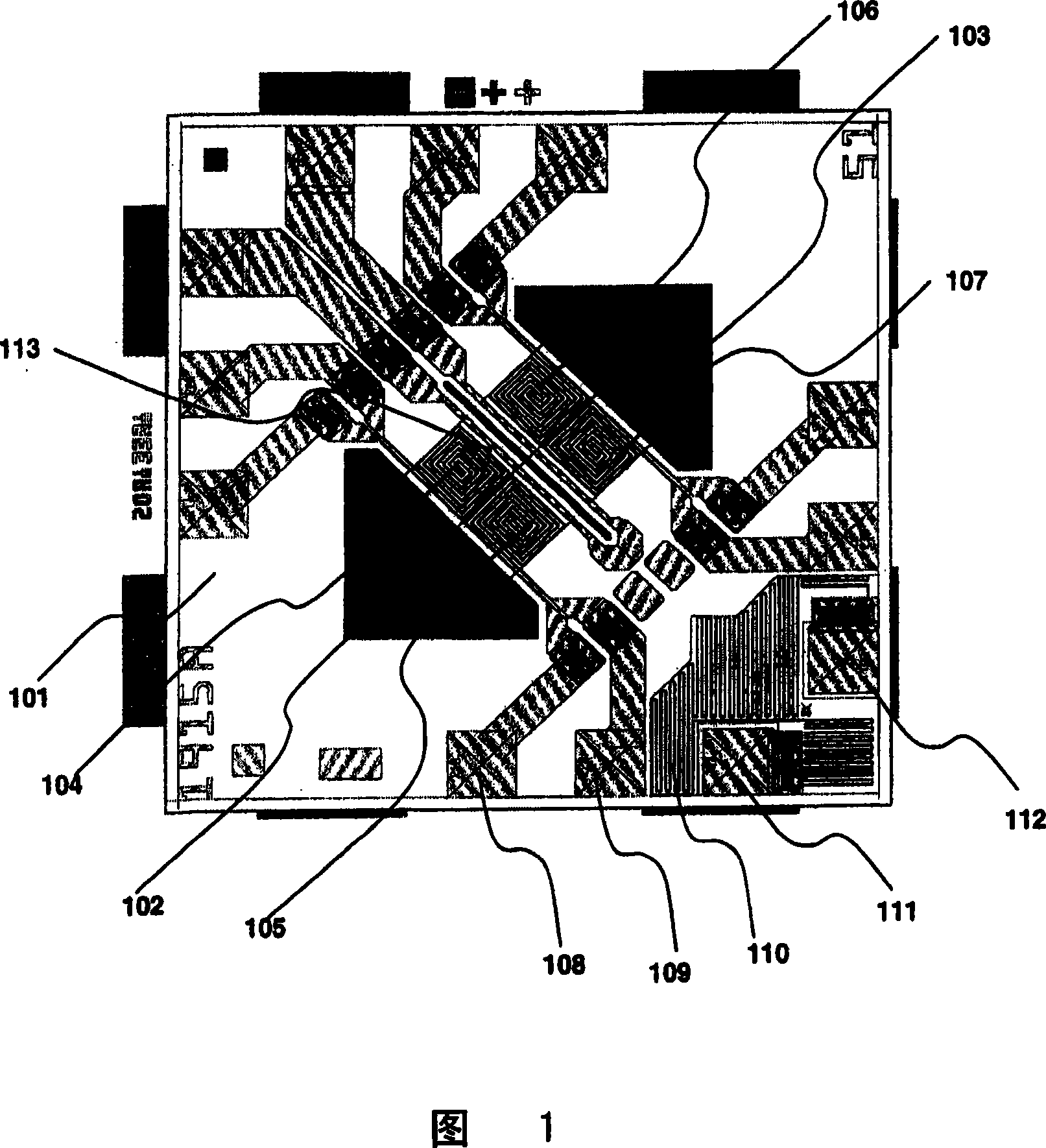

[0023] Figure 1 illustrates a composite top view of all layers residing on a substrate 101 representing a complete flow sensor in accordance with aspects of these embodiments. Fluid may flow from channel inlet 102 to channel outlet 103 . As the fluid flows, it passes the first upstream temperature sensor 104 and the second upstream temperature sensor 105 . The fluid may then be heated by heater 113 . The heated fluid then flows through the first downstream temperature sensor 106 and the second downstream temperature sensor 107 .

[0024] The first contact pad 108 and the second contact pad 109 are electrically connected to the second upstream temperature sensor 105 . Current can flow into the first contact pad 108 , thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com