Integral tester for electric vehicle

A comprehensive tester and electric vehicle technology, applied in the field of comprehensive testers, can solve the problems of lack of comprehensive test equipment and heavy test workload.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

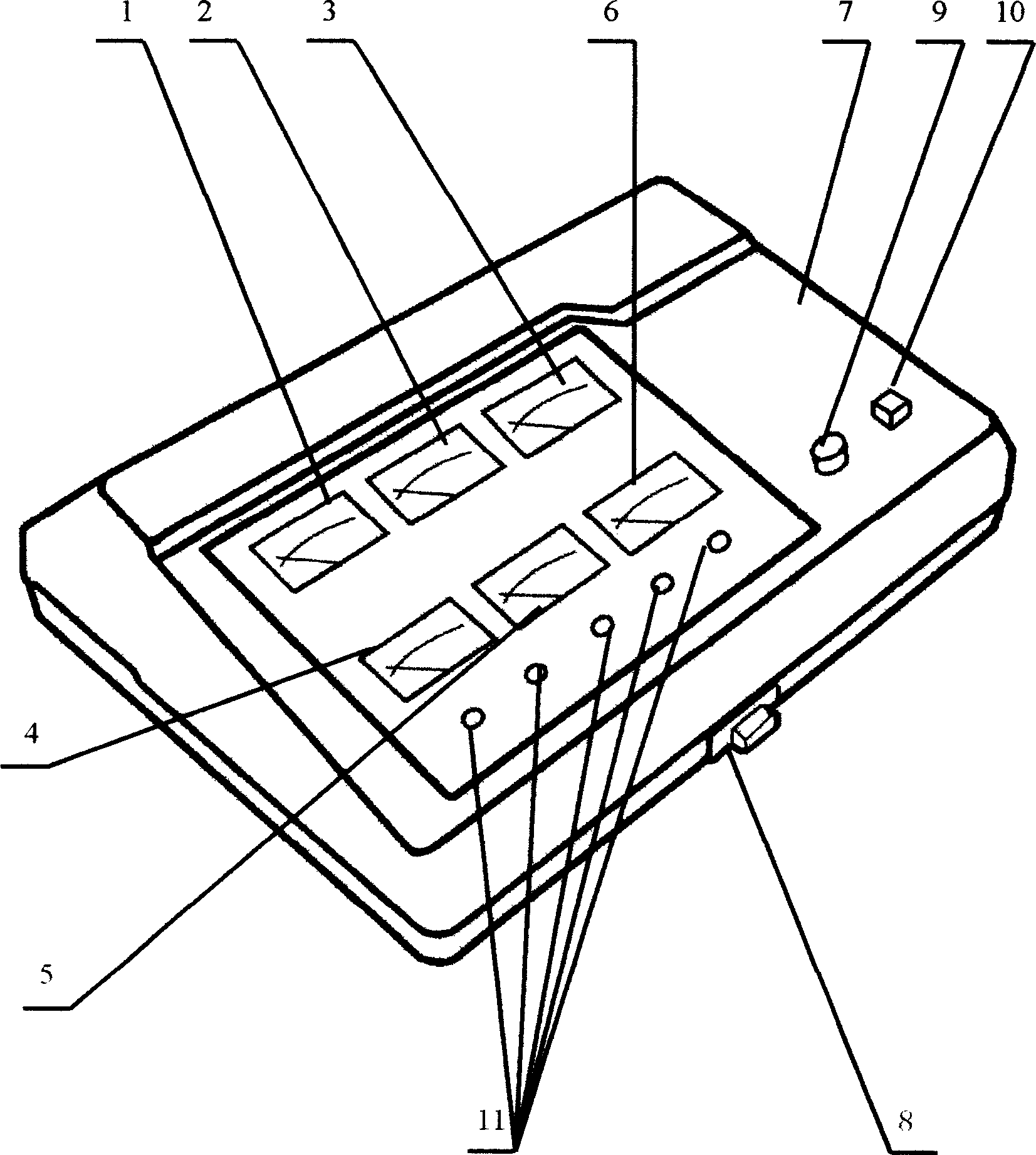

[0012] In the accompanying drawings: A Hall element test voltmeter 1, B Hall element test voltmeter 2, C Hall element test voltmeter 3, handlebar speed test voltmeter 4, handlebar brake test voltmeter 5, constant current power generation Test voltmeter 6, comprehensive tester shell 7, comprehensive tester input interface 8, comprehensive tester power switch 9, selection switch 10, five indicator lights 11.

[0013] The specific working method is as follows:

[0014] An embodiment of the present invention is: the input port 8 of the comprehensive tester can be connected to two test points on the electric vehicle respectively: they can test various performance indicators and failure conditions of the light control and motor control, and provide electric vehicle testing and maintenance services. Hall element A, B, C three lead wires, Hall element positive power supply, handlebar brake lead wire (low potential), handlebar speed control line, controller main power supply positive p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com