Anti-vibration device for switch rocker of sulture hexafluoride gas density relay

A technology of sulfur hexafluoride gas and density relay, which is applied in electrical switches, circuits, electrical components, etc., can solve problems such as accidents, relay failures, displacement detachment, etc., and achieve the effect of simple structure and convenient manufacturing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

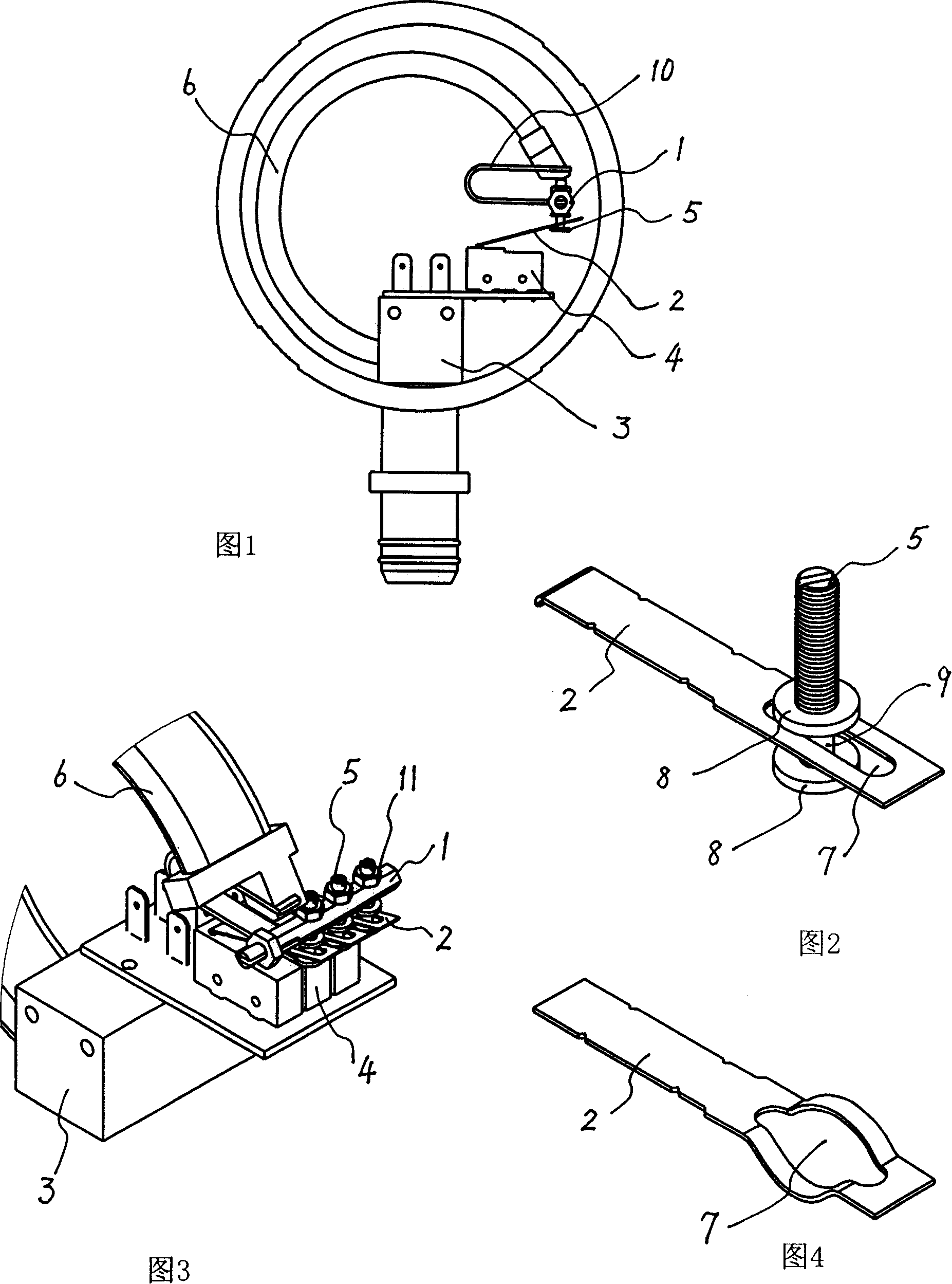

[0015] Referring to Fig. 1, Fig. 2 and Fig. 3, a kind of anti-vibration device of switch pendulum for sulfur hexafluoride gas density relay, comprises push rod 5, switch pendulum 2, one end of expansion tube 6 is connected on fixing base 3, the other end Connected to the connecting seat 1, a section of the ejector rod 5 is threaded, locked and installed on the connecting seat 1 through the nut 11, the switch swing rod 2 is installed on the micro switch 4 to drive the micro switch 4, and the micro switch 4 is installed on the mount 3. There is a groove 9 at the head of the push rod 5, and there is a long hole 7 on the switch swing rod 2. move, so that the head of the ejector rod and the switch swing rod can also be realized; a better embodiment is that there are cylindrical bosses 8 at both ends of the groove 9, and the cylindrical bosses 8 at the head of the ejector rod 5 are clamped Hold the switch swing rod 2 with the long hole 7; in this way, the displacement of the expans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com