Elimination of first wafer effect for pecvd films

A technology of heating gas and radio frequency power, applied in metal material coating process, coating, gaseous chemical plating, etc., can solve the problems of uneven heating of the panel, low deposition rate, uneven deposition on the substrate surface, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

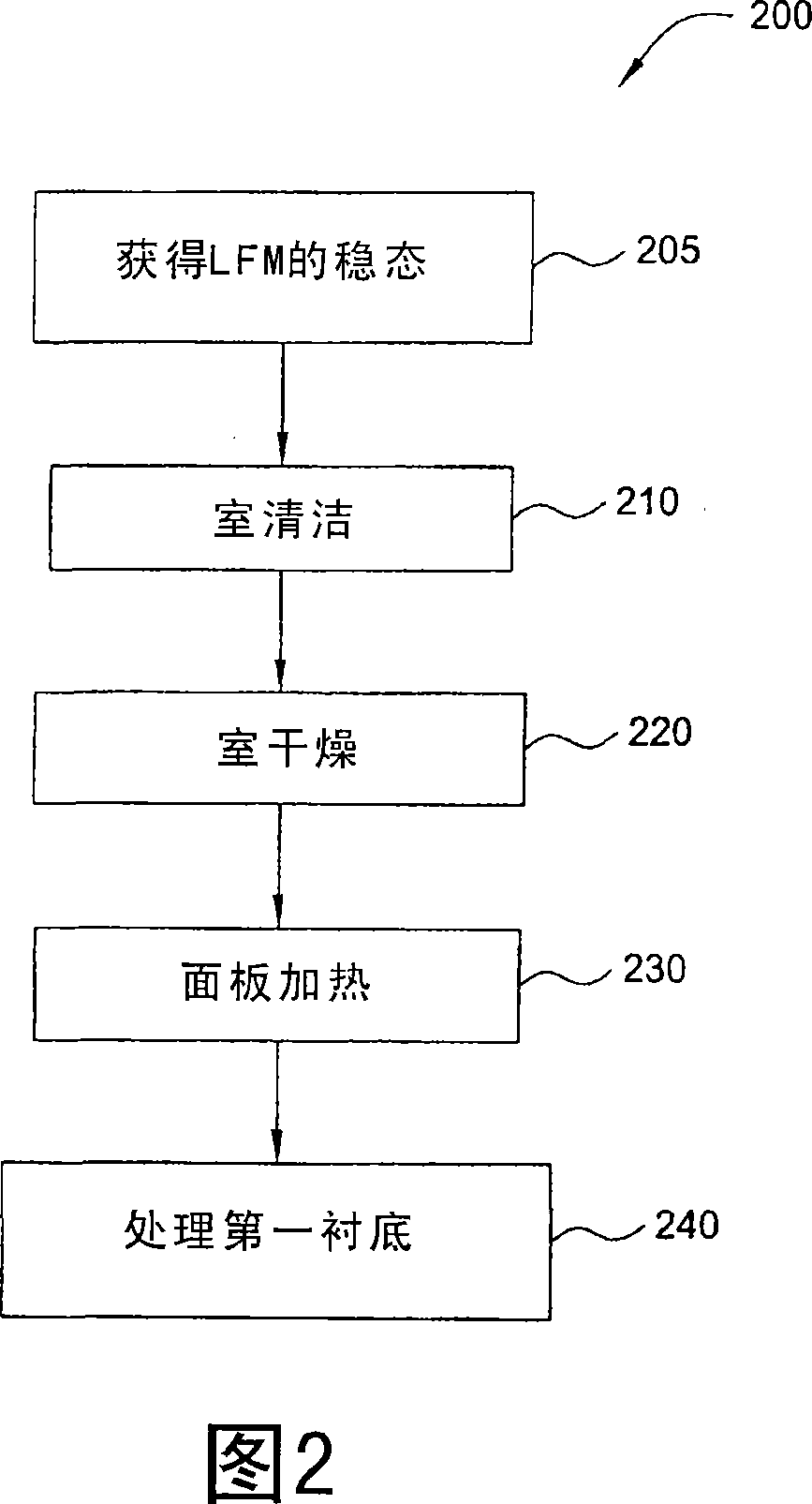

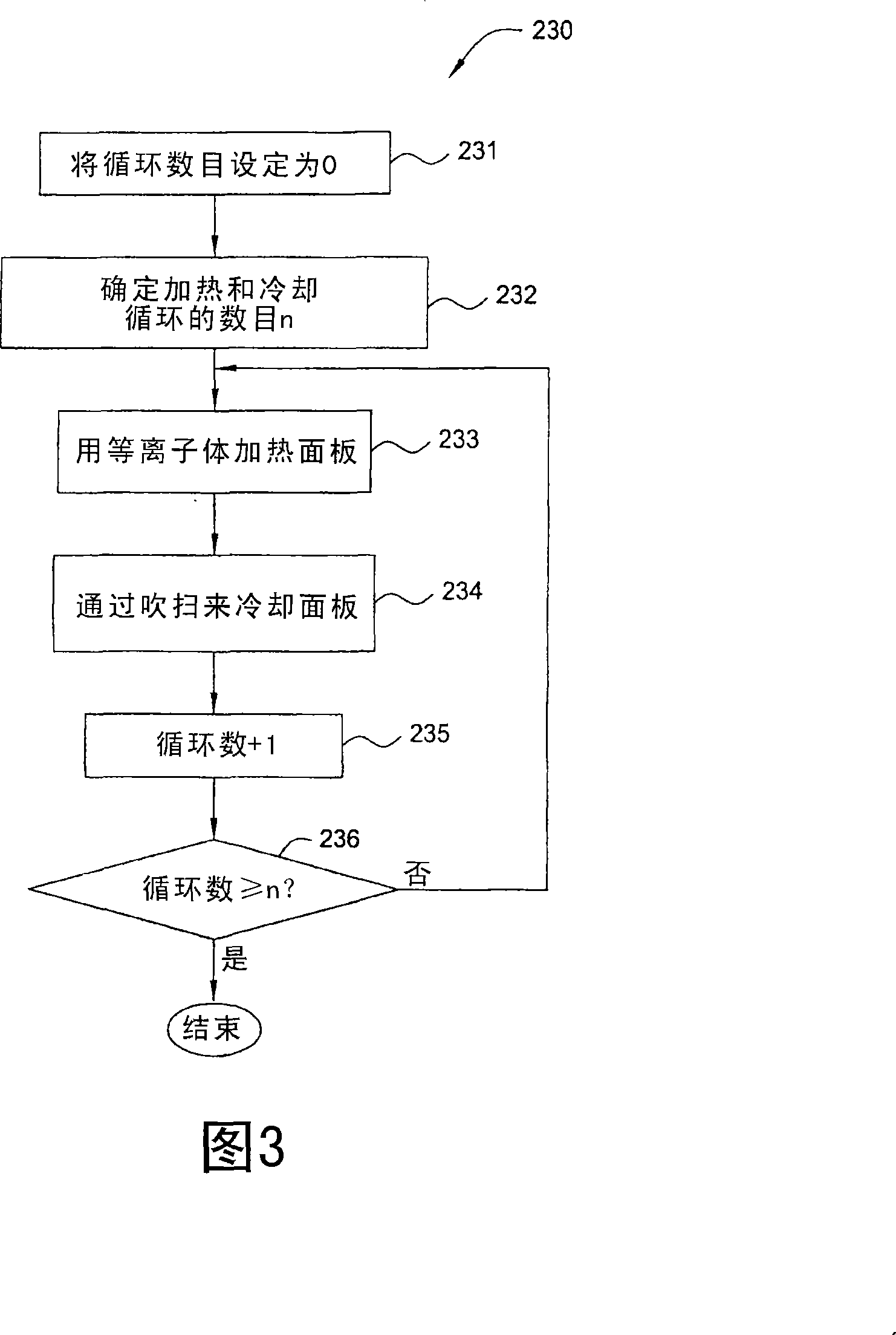

[0015] The present invention generally provides an apparatus and method for eliminating the "first wafer effect". A new "priming" sequence for PECVD was developed. The new "start" sequence includes a cleaning step, a drying step, and a heating step adjusted for the length of idle time. The new "start" sequence takes less time and requires less energy. In addition, the present invention also provides a device and a method for obtaining steady-state performance of the liquid flow meter. The present invention combines a new "start-up" sequence with making the LFM obtain a steady state, greatly reducing or even eliminating the "first wafer effect".

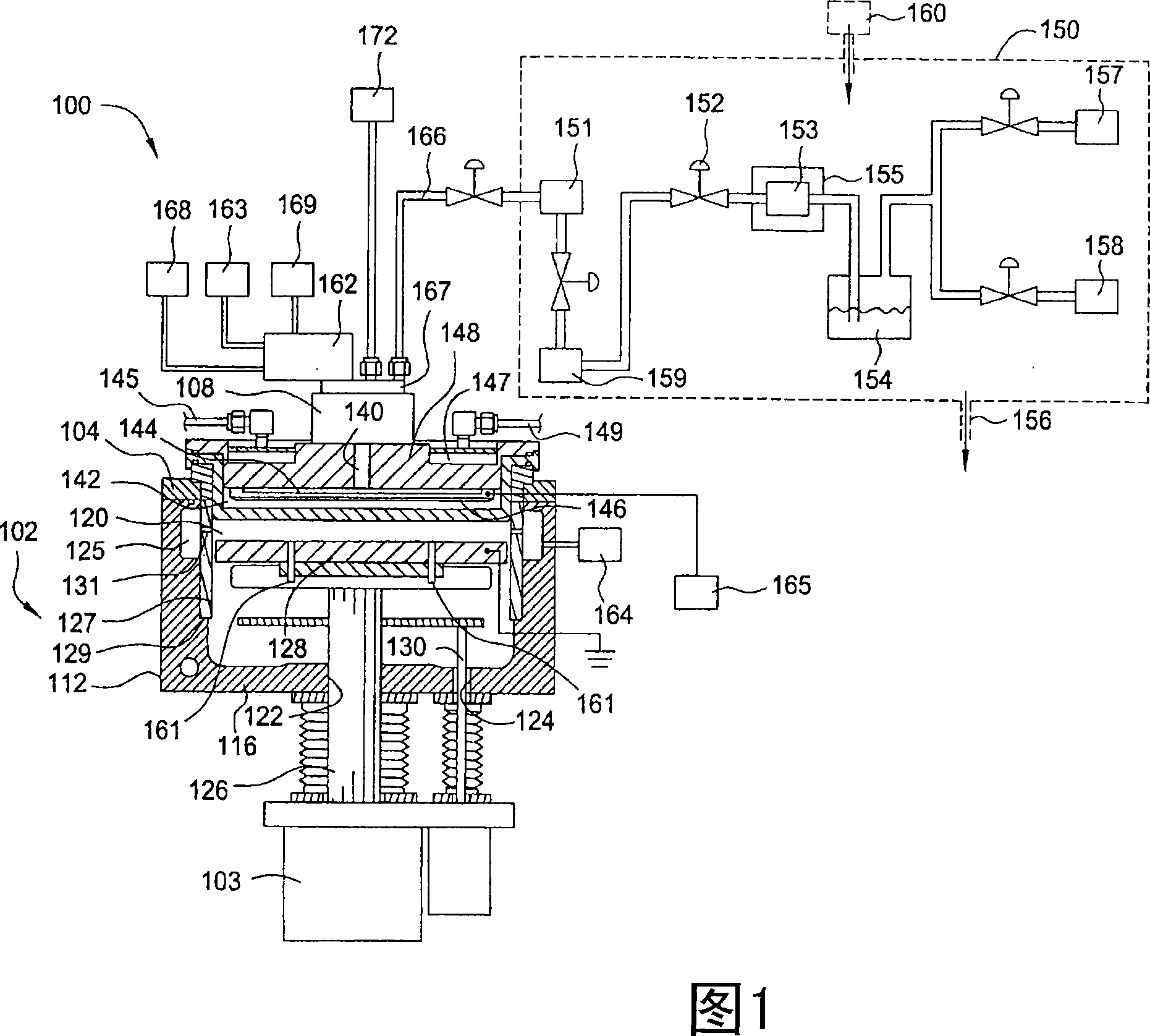

[0016] The following exemplary description of the invention is referenced to PRODUCER SE CVD system or DXZ CVD systems available from Applied Materials, Inc. of Santa Clara, California. Producer SE CVD systems (e.g., 200mm or 300mm) have two isolated process regions that can be used to deposit carbon-doped silicon oxide o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com