Boosting oil cylinder

An oil cylinder and force-increasing technology, which is applied in the field of hydraulic devices, can solve the problems of increasing the structural size of the piston and the oil cylinder, difficulty in transportation and construction, and leakage of seals, and achieves the effect of avoiding the increase in the size of the oil cylinder.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below with reference to specific examples.

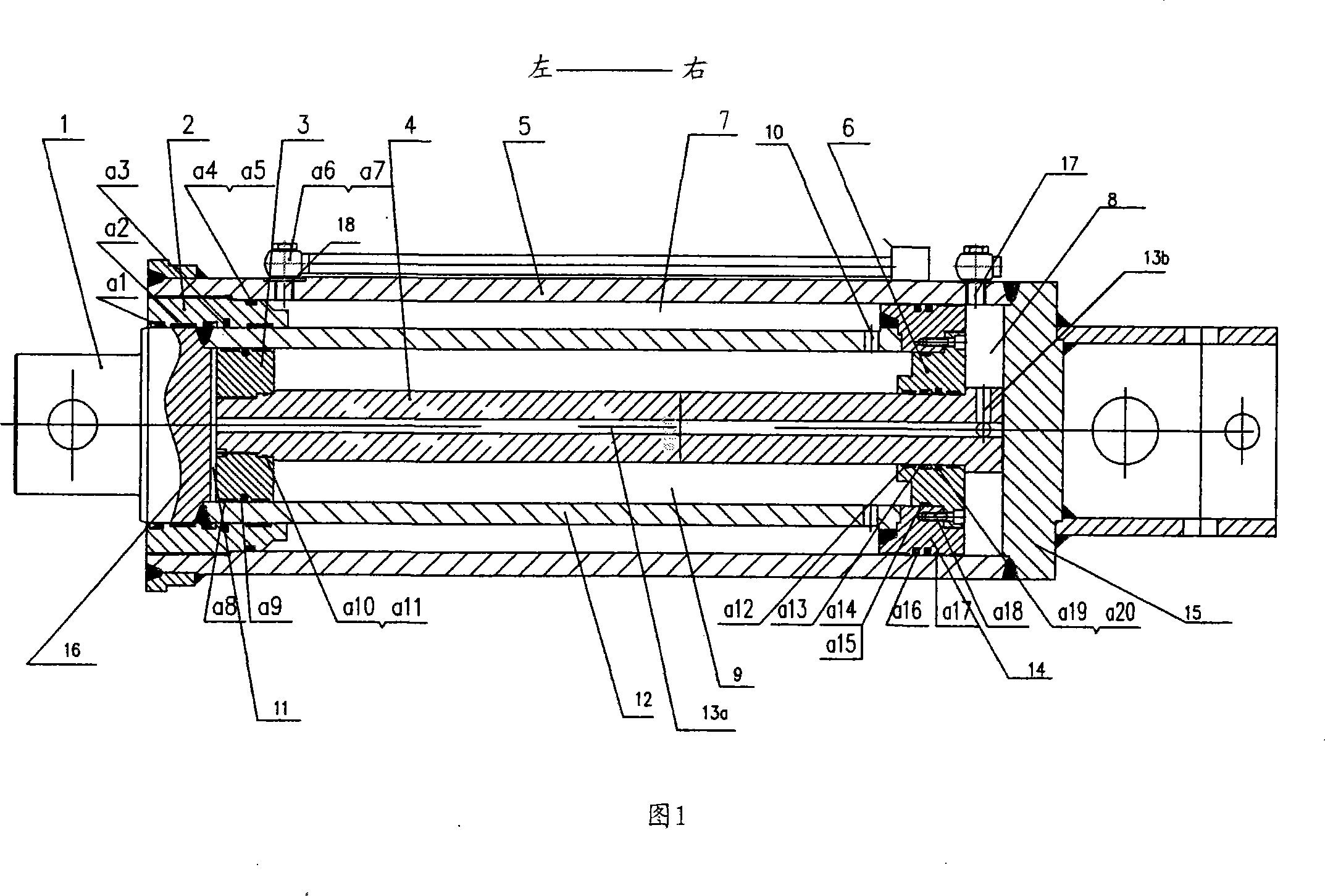

[0023] As shown in Figure 1, Figure 1 is a longitudinal sectional view of the booster cylinder of the present invention. The booster oil cylinder comprises a cylindrical cylinder body 5, the cylinder body 5 has two ends opposite to each other in the axial direction, one end is closed by the cylinder head 15 by being welded into one with the cylinder head 5, and the other end is provided with a large body fixed therewith. The guide sleeve 2, the outer surface of the large guide sleeve 2 and the inner surface of the cylinder body 5 are sealed by an O-ring back-up ring a4 and an O-ring seal a5.

[0024] A large piston rod 1 that is substantially coaxial with the cylinder body 5 is provided. The large piston rod 1 includes a large piston rod main body 12 and a connecting portion 16. The large piston rod main body 12 is cylindrical with a cylindrical cavity inside. A cylindrical s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com