Hydraulic disk type integrated arrestor with adjustable braking force

A hydraulic brake and braking force technology, applied in the direction of hydraulic brakes, brake types, brake components, etc., can solve the problems of high price, hidden danger of brake failure, cumbersome friction plate replacement procedures, etc., to achieve convenient replacement and maintenance, accurate estimated effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

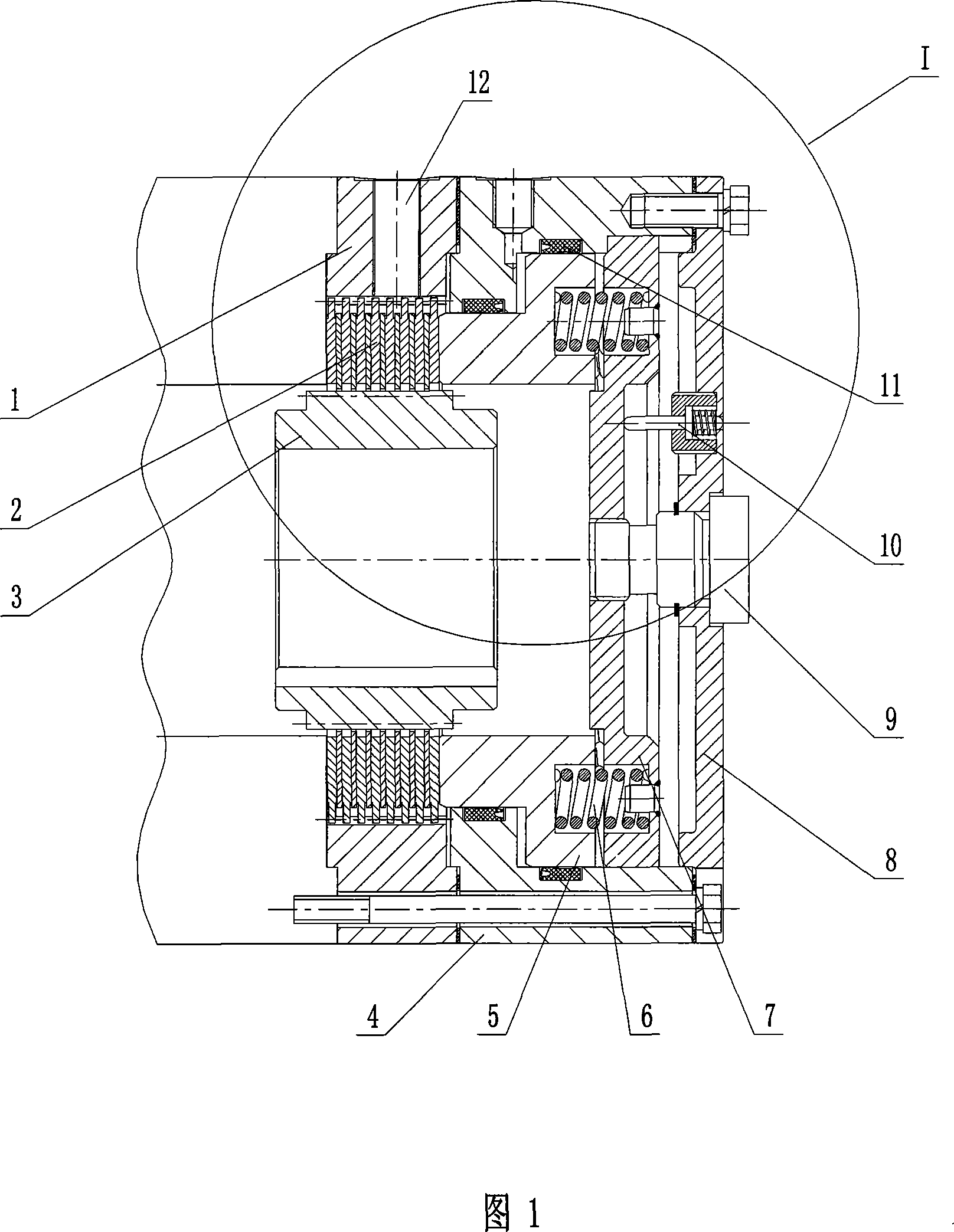

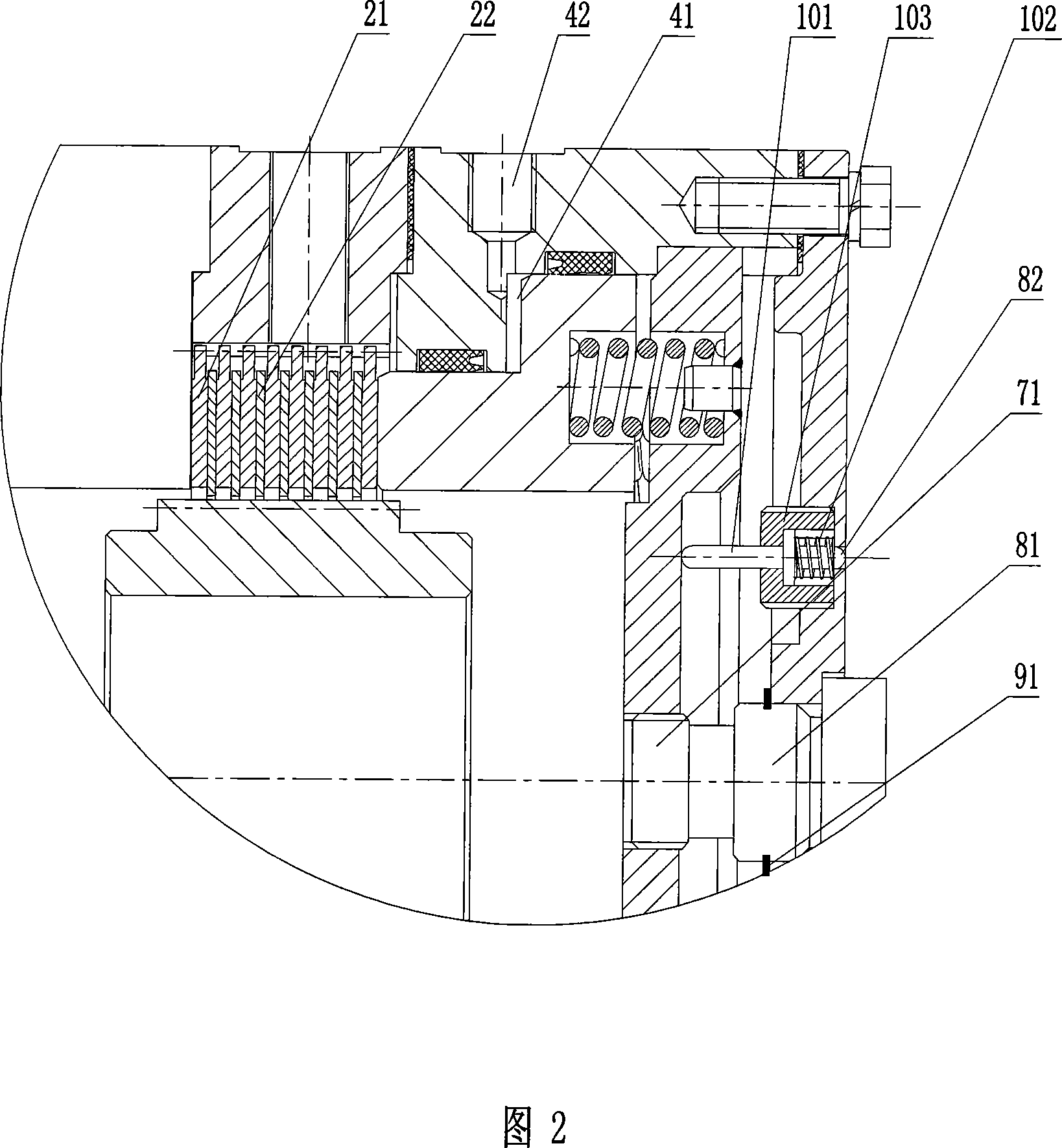

[0025] As shown in Figures 1 and 2, the disc hydraulic brake with adjustable braking force of the present invention includes a working device and a power device. The shaft outer gear 3 is located in the inner gear ring 1, and the friction plate group 2 is arranged between the shaft outer gear 3 and the inner gear ring 1; the power device consists of a casing 4, a piston 5, a compression spring 6, a baffle plate 7 and a seal 11 Composition, the piston 5 and the baffle 7 are sleeved in the casing 4, one end of the piston 5 is connected to the friction plate set 2, and the other end is connected to the baffle 7 through a compression spring 6, and the seal 11 is arranged on the outer wall of the piston 5 and the casing Between the inner walls of 4, the shell 4 is connected with the inner gear ring 1 through fasteners. The present invention also includes an adjustment device, which is composed of an end cover 8, a detection device 10 and an adjustment screw 9. The end cover 8 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com