Ink jet printing

An inkjet module and ink nozzle technology are applied in inkjet printing. field, to achieve the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

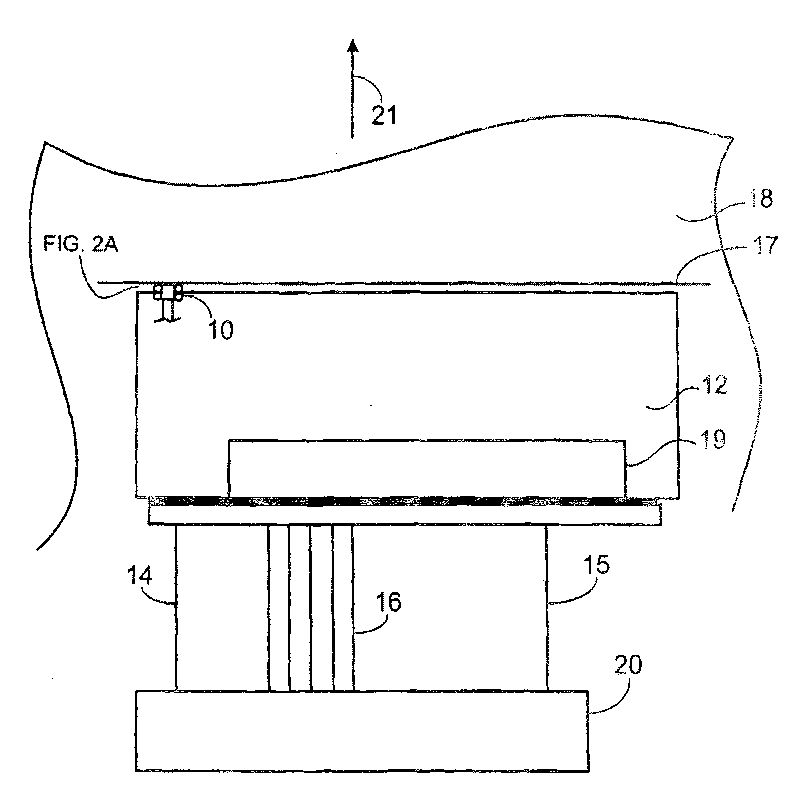

[0036] Refer to attached figure 1 , the inkjet module 12 includes a plurality (eg, 16, 64, 128, 256, 512 or more) of ink nozzles 10 driven by electrical drive pulses (in the attached figure 1 Only one is shown in ), the electrical drive pulses are provided on signal lines 14 and 15 and distributed by an on-board control circuit 19 in order to control the firing of the ink nozzles 10 . External controller 20 provides drive pulses on lines 14 and 15 and control data and logic power and timing to onboard control circuitry 19 on additional line 16 . Ink ejected by ink nozzles 10 may be delivered to form one or more print lines 17 on substrate 18 moving relative to inkjet module 12 (eg, in the direction indicated by arrow 21 ). In some embodiments, the substrate 18 moves past the stationary head module 12 in a single-pass mode. Optionally, inkjet module 12 may also be moved across substrate 18 in a scanning manner.

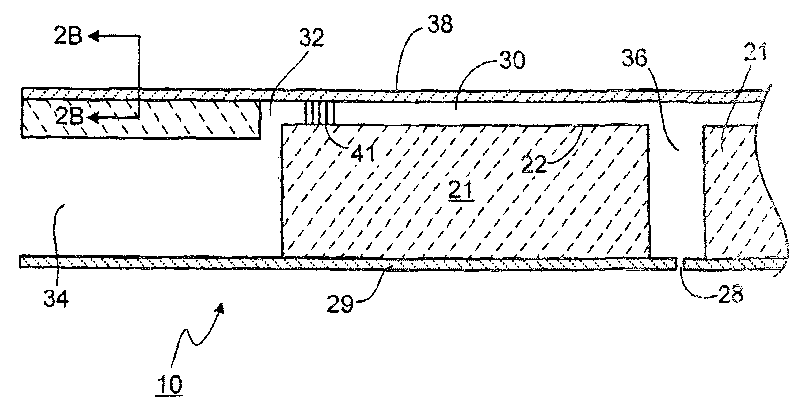

[0037] Refer to attached Figure 2A(Illustrating vertical sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com